Formation method of contact hole

A contact hole and cushion technology, which is applied in the direction of semiconductor/solid-state device components, electrical components, circuits, etc., can solve the problems of increased contact hole resistance, and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

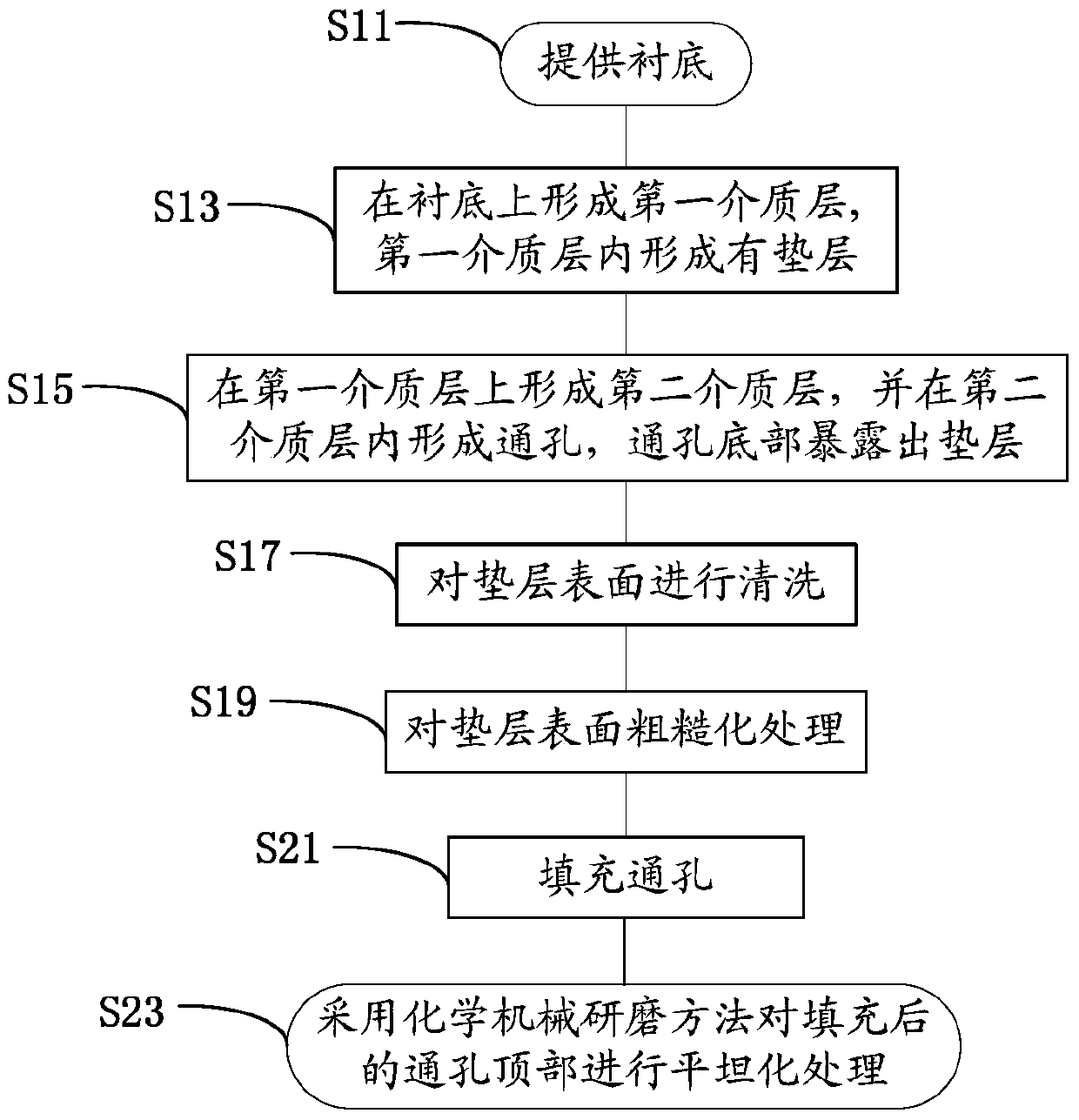

[0025] Embodiments of the present invention provide a method for forming a contact hole, which will be described in detail below with reference to the accompanying drawings:

[0026] It should be noted that in this embodiment, the formation of a single damascene structure is taken as an example for illustration, and the method of the present invention can also be applied to other via structures, such as plug or straight via structures, which will not be listed here.

[0027] refer to figure 1 In step S11 and Figure 4 , providing a semiconductor substrate 10 .

[0028] The semiconductor substrate 10 can be single crystal silicon or polycrystalline silicon; the semiconductor substrate 10 can also be selected from silicon, germanium, gallium arsenide or silicon germanium compound; the semiconductor substrate 10 can also be other semiconductor materials; The semiconductor substrate 10 can also be selected from having an epitaxial layer or a silicon-on-epitaxial structure; and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com