Cmp slurry composition for polishing polycrystalline silicon and polishing method using same

A polysilicon and composition technology, applied in polishing compositions containing abrasives, chemical instruments and methods, other chemical processes, etc., can solve the problems of loss of polysilicon film, reduction of process reliability, inability to selectively remove protrusions, etc. , to achieve the effect of improving surface roughness and increasing removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

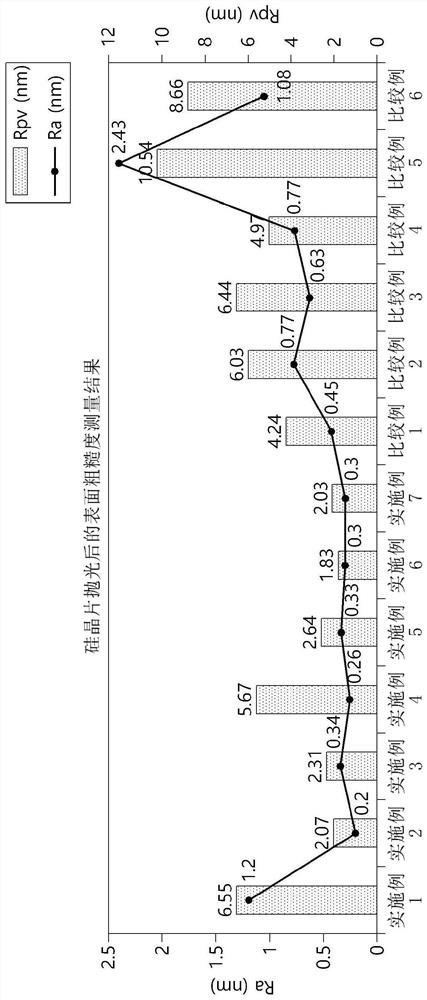

Embodiment 1

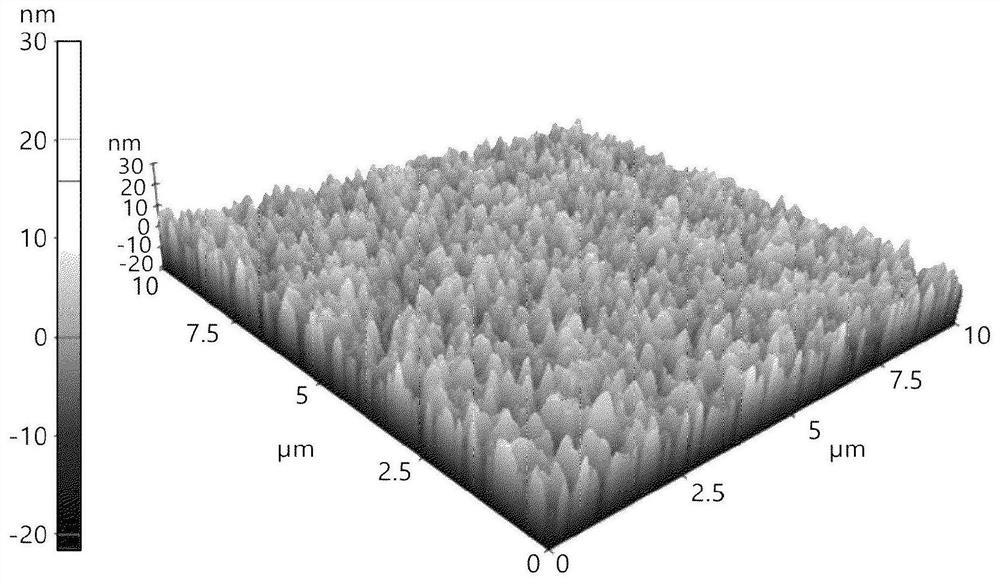

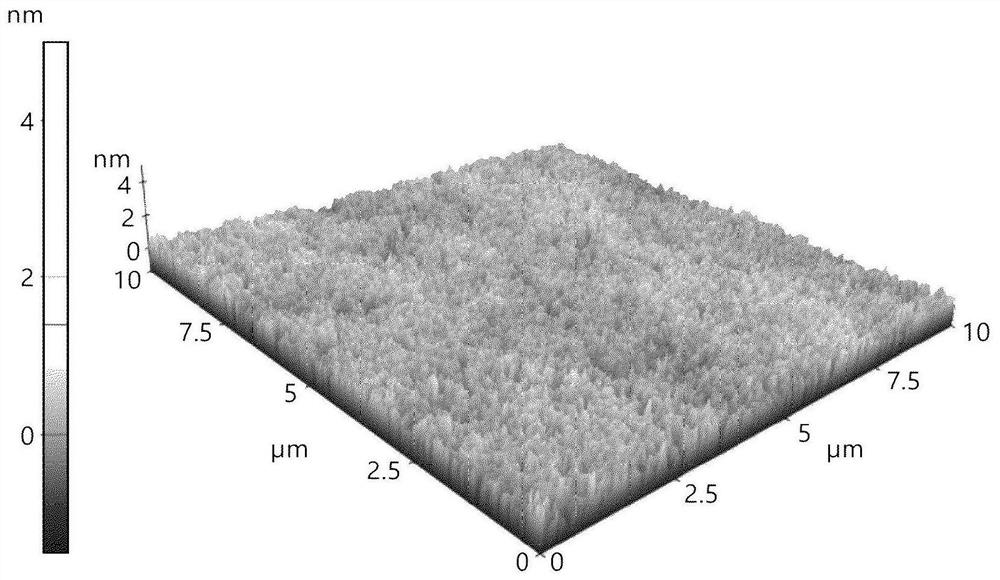

[0070] Add 1% by weight of surface-modified colloidal cerium oxide polishing particles (PL-3D) with a particle size of 80 nm, 0.3% by weight of succinic acid as a carboxylic acid, and hydroxyethyl ether with a weight average molecular weight of 90,000 as a surface roughness modifier. A CMP slurry composition for polishing polysilicon having a pH value of 4 was prepared by mixing 0.05% by weight of cellulose-based cellulose (HEC) with triethanolamine as a pH adjuster.

[0071] By using the CMP slurry composition for polishing polysilicon, under the evaluation conditions, the pressure was set to 1 psi, the carrier rotation speed (RPM) / platen rotation speed (RPM) was set to 78 / 83, and the polishing time was set to 15 seconds and carried out polishing.

Embodiment 2

[0073] Polishing was performed for 60 seconds by using the same CMP slurry composition for polishing polysilicon as in Example 1.

Embodiment 3

[0075] In Example 1, a CMP slurry composition for polishing polysilicon was prepared in the same manner as in Example 1 except that 0.1% by weight of hydroxyethylcellulose (HEC) was added.

[0076] In Example 1, polishing was performed in the same manner as in Example 1 except for polishing for 60 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com