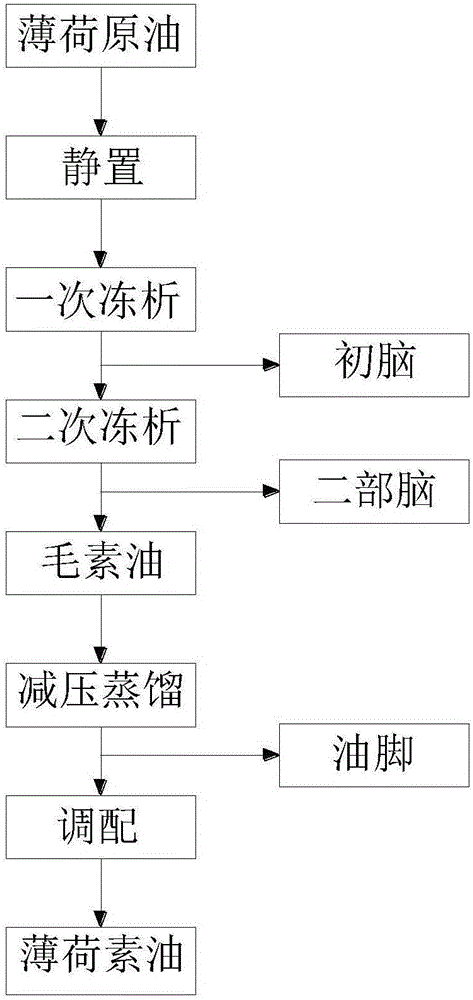

Production process of peppermint oil

A production process, the technology of mint oil, applied in the field of chemical industry, can solve the problems of complex components of mint oil, loss of volatile oil, low quality, etc., and achieve the effect of narrowing the range of collected fractions, uniform product phase, and uniform product phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Stand still: put the qualified peppermint crude oil in a static tank, keep the temperature at 40-60°C, keep the mint crude oil in a liquid state without freezing, and let it stand for 24 hours. After the standing is completed, separate the water and impurities at the bottom, and remove The water impurities in the raw materials are beneficial to freeze-out to obtain a purer product.

[0022] 2), one-time freeze-out: adopt the mixture of the mint crude oil and ice oil after standing, the ice oil is the mother liquor after crystallization in the process of producing menthol, and the mixing mass ratio of the mint crude oil and ice oil is 2:0.8 , input the mixed material into the freeze-out tank, feed low-temperature brine into the coil of the freeze-out tank, and turn on the frozen brine pump to cool down gradually, and the amount of brine pumped increases from small to large. When the temperature of the brine reaches -26 to -30°C, the refrigeration is stopped, and the b...

Embodiment 2

[0027] 1) Stand still: put the qualified peppermint crude oil in a still tank, keep the temperature at 40-60°C, let stand for 23 hours, and separate the water and impurities at the bottom after the stand is completed.

[0028] 2), one-time freeze-out: adopt the mixture of mint crude oil and ice oil after standing, the mixing mass ratio of described mint crude oil and ice oil is 2:0.5, the material after mixing is input in the freeze-out tank, gradually cool down, By controlling the freeze-out temperature, the amount of secondary oil is 40% to 50% of the total mass of raw materials.

[0029] 3), secondary freeze-out: adopt the mixture of two parts oil and ice oil, the mixing mass ratio of described two parts oil and ice oil is 1:1, input two parts oil and ice oil mixture in the freeze-out tank, and The primary freeze-out is similar, and the amount of crude oil is 50% to 60% of the total mass of the secondary oil and ice oil by controlling the freeze-out temperature.

[0030] 4...

Embodiment 3

[0033] 1) Stand still: put the mint crude oil that has passed the inspection in a still tank, keep the temperature at 40-60°C, and let it stand still for 25 hours. After the standing is completed, separate the water and impurities at the bottom.

[0034] 2), one-time freeze-out: adopt the mixture of mint crude oil and ice oil after standing, the mixing mass ratio of described peppermint crude oil and ice oil is 2:1, the material after mixing is input in the freeze-out tank, gradually cool down, By controlling the freeze-out temperature, the amount of secondary oil is 40% to 50% of the total mass of raw materials.

[0035] 3), secondary freeze-out: adopt the mixture of two parts oil and ice oil, the mixing mass ratio of described two parts oil and ice oil is 1:1.5, input two parts oil and ice oil mixture in the freeze-out tank, and The primary freeze-out is similar, and the amount of crude oil is 50% to 60% of the total mass of the secondary oil and ice oil by controlling the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com