Fluoro-rubber adhesive tape and manufacturing method thereof

A production method and technology of fluororubber, which is applied to rubber layered products, chemical instruments and methods, and other household appliances, etc., can solve problems such as difficulty in bonding, hardening of the hand, and delamination of protective materials, achieving obvious functional advantages and production The effect of low cost and high protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

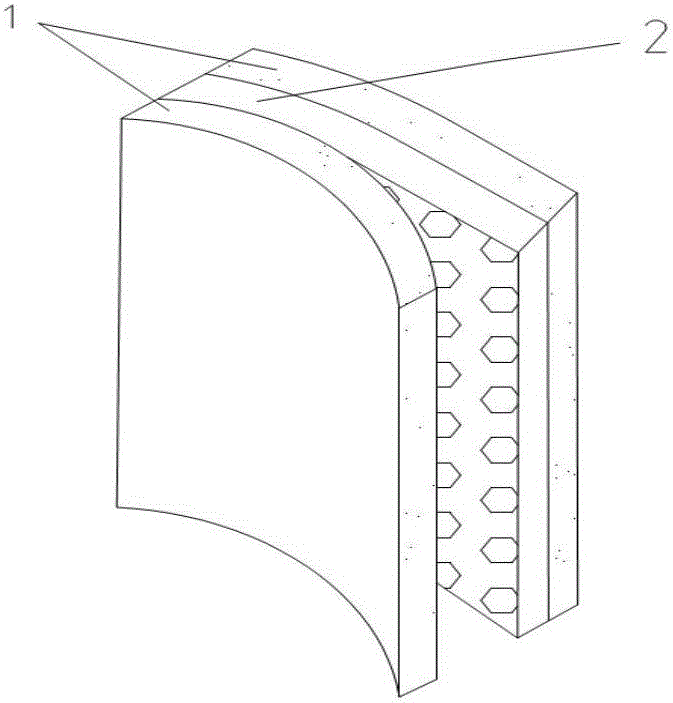

Image

Examples

Embodiment 1

[0019] 100 parts of fluororubber, 10 parts of magnesium hydroxide, 15 parts of calcium hydroxide, 3 parts of anti-aging agent, 5 parts of vulcanizing agent, and 30 parts of titanium dioxide are masticated and kneaded to form a rubber compound;

[0020] The mixed rubber is calendered to prepare a continuous tape with a thickness of 0.15mm, the calendering temperature is 80°C, and the speed is 20m / min;

[0021] Place the grid fabric between two layers of rubber cloth, and carry out drum vulcanization at a temperature of 170°C for 10 minutes, so that the calendered rubber cloth and the grid fabric can be vulcanized and bonded to form a fluororubber rubber cloth.

[0022] The thickness of the fluorine rubber adhesive plaster prepared by the above method is 0.40mm, and the weight is 550g / m 2 . The peeling fastness to the base fabric is 0.81N / m, the limiting oxygen index is 29, and the breaking strength can reach 350N / 5cm. It is resistant to 98% sulfuric acid, 40% sodium hydroxide,...

Embodiment 2

[0024] Plasticize and knead 100 parts of fluororubber, 15 parts of calcium hydroxide, 2 parts of anti-aging agent, 6 parts of vulcanizing agent and 20 parts of titanium dioxide to form a mixed rubber.

[0025] The mixed rubber is calendered into a continuous rubber cloth with a thickness of 0.18mm by calendering, the calendering temperature is 80°C, and the speed is 20m / min.

[0026] Vulcanization lamination: Put the aramid mesh fabric between two layers of fluororubber tapes, enter the drum for vulcanization, and apply slight tension to the three layers of materials to ensure smoothness when entering the drum vulcanization equipment. The vulcanization temperature is 180°C, and the guaranteed vulcanization time is 10 minutes.

[0027] The thickness of the fluorine rubber adhesive plaster that present embodiment makes is 0.45mm, and limiting oxygen index is 36.4, and breaking strength can reach 500N / 5cm, and the nitric acid of 98% concentrated sulfuric acid, 40% sodium hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com