Flame-retardant corrosion-resistant watertight door

A watertight door and corrosion-resistant technology, which is applied to the layout of watertight doors, door leaves, fire doors, etc., can solve the problems of large corrosion damage to the hull, easy fire accidents, weak impact resistance, etc., and achieve fire prevention and corrosion resistance. Long-lasting and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

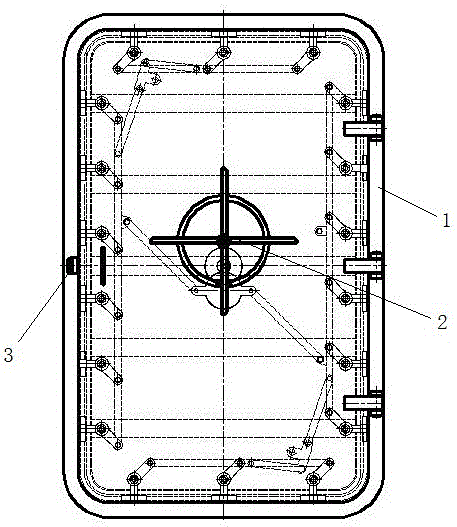

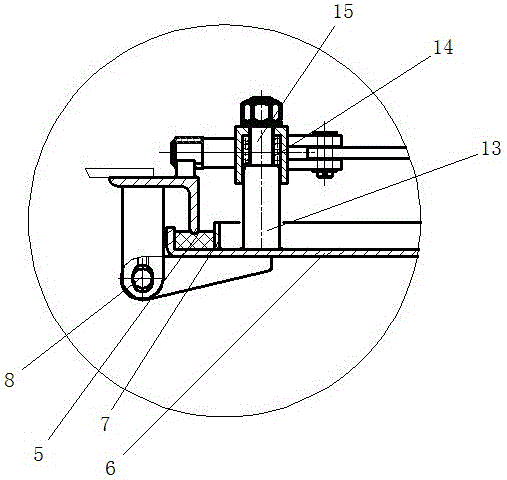

[0023] Such as figure 1 , 2 A fireproof and pressure-resistant watertight door shown in . 3. A shroud 7 is arranged along the inner side of the edge of the door panel 6 along the circumference, and an installation groove 9 is formed between the shroud 7 and the edge of the door panel 6, and the installation groove 9 is filled with a gasket 5, and the gasket 5 5 includes a sponge body, a glue layer and a rubber foreskin, the glue layer is coated on the surface of the sponge body, and the rubber foreskin is wrapped on the outer surface of the glue layer;

[0024] The inside of the door panel 6 is provided with an inner cover 17, and the inner cover 17 is fixed on the enclosure 7, as Figure 6 As shown, a sound-absorbing layer 18 and a lightweight sound-insulating panel 19 are provided between the inner cover 17 and the door panel 6. Between, the surface of the door panel 6 is coated with an anti-corrosion paint layer, and the surface of the lightweight sound-insulating board ...

Embodiment 2

[0027] On the basis of Example 1, the raw material components and weight content of the anticorrosion coating layer are as follows: 20-30 parts of phenolic resin, 10-15 parts of soybean oil, 30-40 parts of petroleum pitch, 3-5 parts of red lead, 2-3 parts of zinc powder, 5-7 parts of mica iron oxide, 2-3 parts of talcum powder, 1-3 parts of diatomaceous earth, 3-5 parts of plasticizer, 1-3 parts of thixotropic agent, 2 parts of mold inhibitor -4 parts; We provide a kind of method for preparing described anticorrosion paint layer, comprise the following steps, earlier equip each component material according to quantity, phenolic resin is made the phenolic resin particle that diameter is less than 5mm by crusher, will prepare Put the standard petroleum asphalt into the reaction kettle, heat up to 200°C, stir continuously during the heating process until the petroleum pitch is completely melted; reduce the temperature of the reaction kettle to 100-120°C, add soybean oil, red lead,...

Embodiment 3

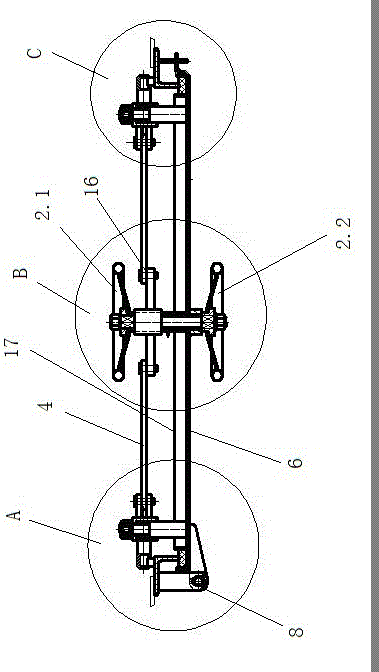

[0033] On the basis of Embodiment 1 or 2, a handwheel device is provided in the middle of the door panel 6, and the handwheel device 2 includes an inner handwheel 2.1, an outer handwheel 2.2 and a handwheel shaft 10, and the two ends of the handwheel shaft 10 are Respectively protrude the door panel 6 and install the inner handwheel 2.1 and the outer handwheel 2.2 respectively at both ends; a first mobile sleeve 11 is arranged between the inner handwheel 2.1 and the door panel 6, and the first mobile sleeve 11 is fixed There is an astrolabe 12, and a plurality of buckle seats 13 are arranged around the door panel, and a second moving sleeve 14 is arranged in the described buckle seat 13, and a guide shaft 15 is arranged in the second moving sleeve 14 to guide The top of the shaft 15 is provided with a guide hole along the radial direction of the guide shaft 15, and the astrolabe 12 is provided with a plurality of pins 16, and the astrolabe 12 is connected with one end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com