High-cyanide-content wastewater treatment system and treatment method

The technology of a treatment system and a treatment method is applied in the high cyanide wastewater treatment system and treatment field, which can solve the problems of difficult biochemical treatment, excessive chloride ions, and many input equipment, and achieves the effects of low cost, simple operation, and less input raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

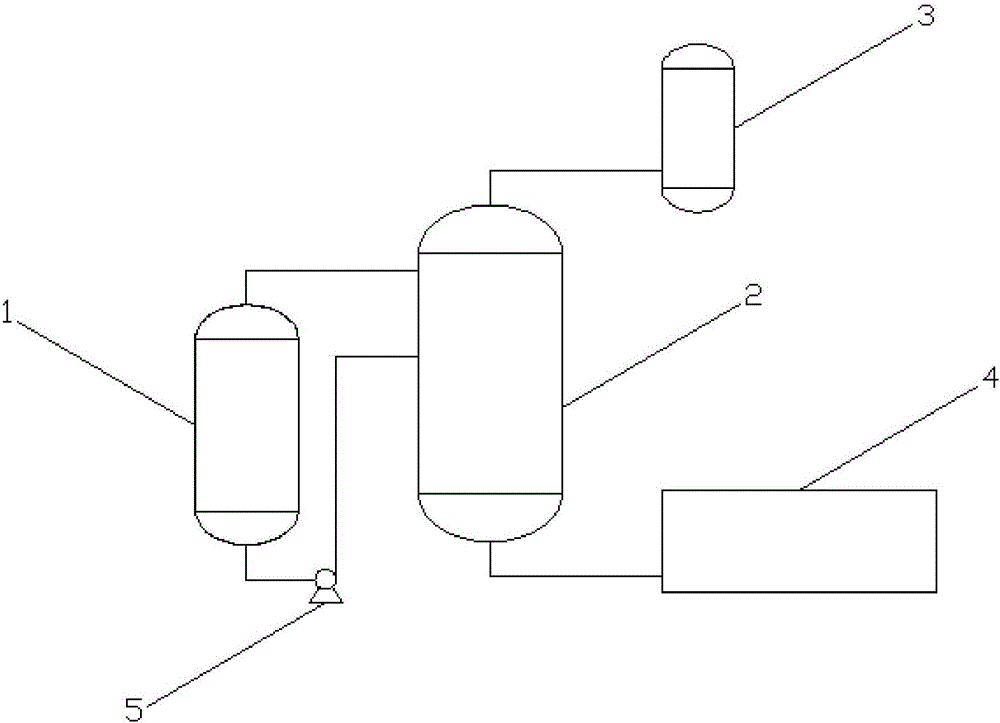

[0012] Such as figure 1 As shown, the high-cyanide wastewater treatment system includes a reactor 1, a deamination tower 2, an absorption device 3, and a water storage tank 4; the outlet of the reactor 1 is divided into a gas outlet and a liquid outlet, and the gas outlet at the top is connected to the deamination tower 2. The liquid outlet at the bottom is connected to the deamination tower 2 through the tank bottom pump 5; the deamination tower 2 is provided with an air inlet connected to the external air, and a fan is installed inside it; the air outlet of the deamination tower 2 is connected to the absorption device 3 , the liquid outlet of the deamination tower 2 is connected to the water storage tank 4, and the absorption device 3 is equipped with dilute sulfuric acid.

[0013] The method for treating high-cyanide wastewater comprises the following steps: firstly, the wastewater containing sodium cyanide is collected in a reactor 1, and the temperature in the reactor 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com