A Dynamic Observation and Control System of Air Flotation Microbubbles

A control system and micro-bubble technology, which is applied in the direction of measuring devices, water treatment parameter control, flotation water/sewage treatment, etc., can solve the problems of limitations, real-time monitoring powerlessness, and inability to respond to the size of bubbles in the contact area in time to achieve measurement The bubble size is accurate and the effect of enhancing the control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

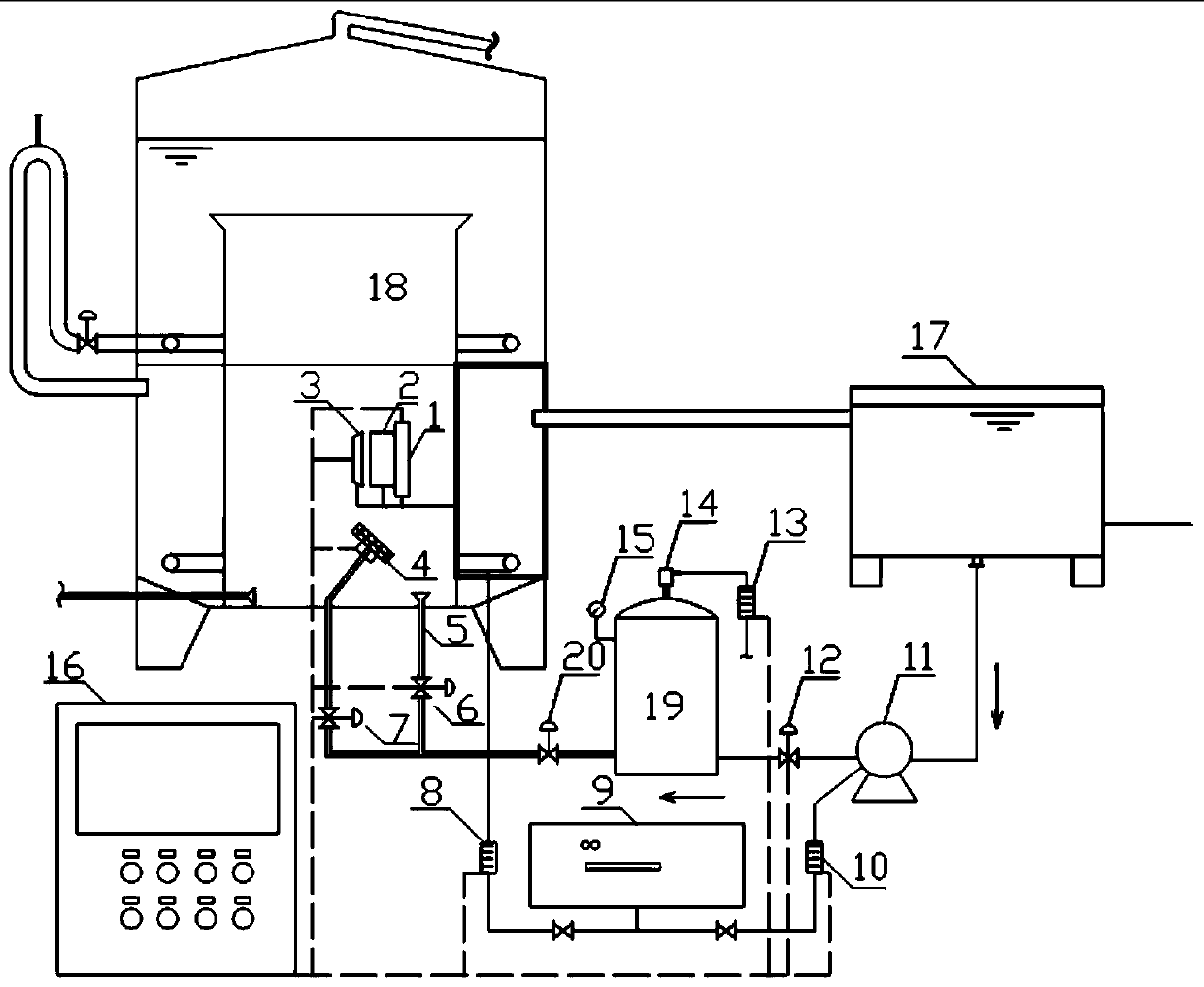

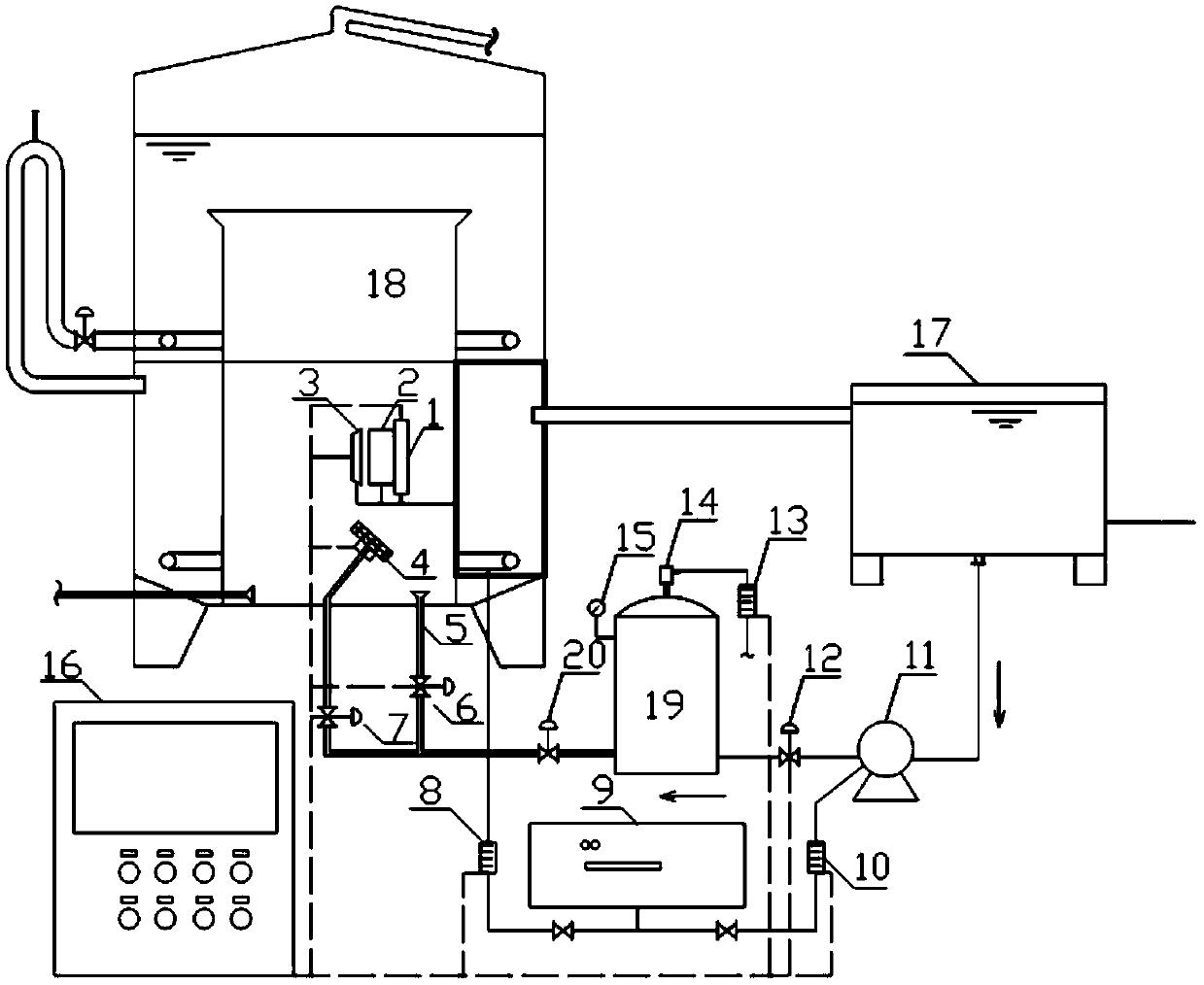

[0022] Such as figure 1 As shown, a dynamic observation and control system for air-floating microbubbles, including:

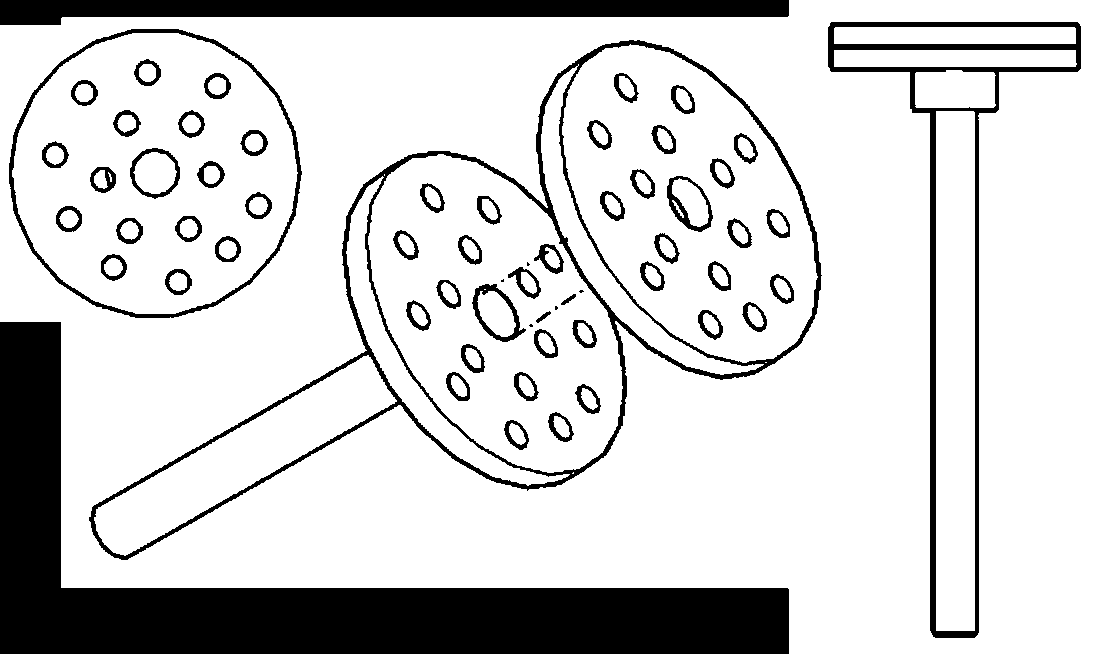

[0023] A bubble dynamic test device composed of a beam transmitter 3, a metering tank 2 and a photodiode receiver 1 arranged in the air flotation area 18; the metering tank 2 is a cuboid with a fixed volume, and the gas produced by passing through a unit volume in a unit time is measured. The pulse signal is used to represent the number of bubbles, and the density of the bubbles can be obtained. If the volume of the contact area is known, the total number of bubbles can be calculated.

[0024] The pressure relief valve gas meter 13 arranged on the pressure tank 19;

[0025] The air flotation gas meter 10 and the oxidation gas meter 8 are respectively installed on the two paths separated from the outlet of the ozone generator 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com