Method for degrading phenol by solid catalyst

A solid catalyst and phenol technology, which is applied in the field of environment and chemical engineering, can solve the problems of phenol technology and patents that have not yet been found, and achieve the effect of not being prone to secondary pollution and releasing less metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

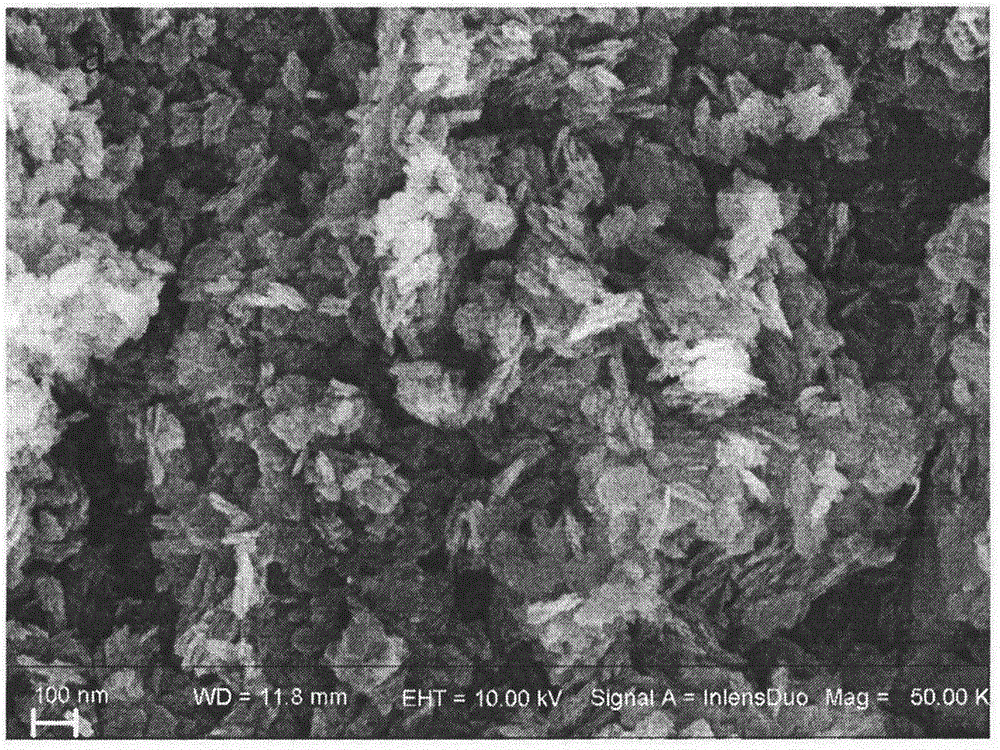

Image

Examples

Embodiment 1

[0025] (1) Fully dissolve 1.125g copper nitrate and 3.492g cobalt nitrate in 100mL pure water;

[0026] (2) Add 2M sodium hydroxide solution to obtain suspension in step (1);

[0027] (3) magnetically stirring the suspension obtained in (2) for 24 h;

[0028] (4) centrifuging the suspension liquid phase formed by the above reaction, then washing with water and ethanol 3 times to obtain a precipitate;

[0029] (5) Place the precipitate in step (4) in a drying oven for 24 hours at 80°C;

[0030] (6) The catalyst precursor formed in step (5) was fully ground and then calcined in a muffle furnace at 6°C min -1 Calcined at a heating rate of 200°C for 1 hour in an air atmosphere, and cooled naturally to room temperature to obtain the catalyst;

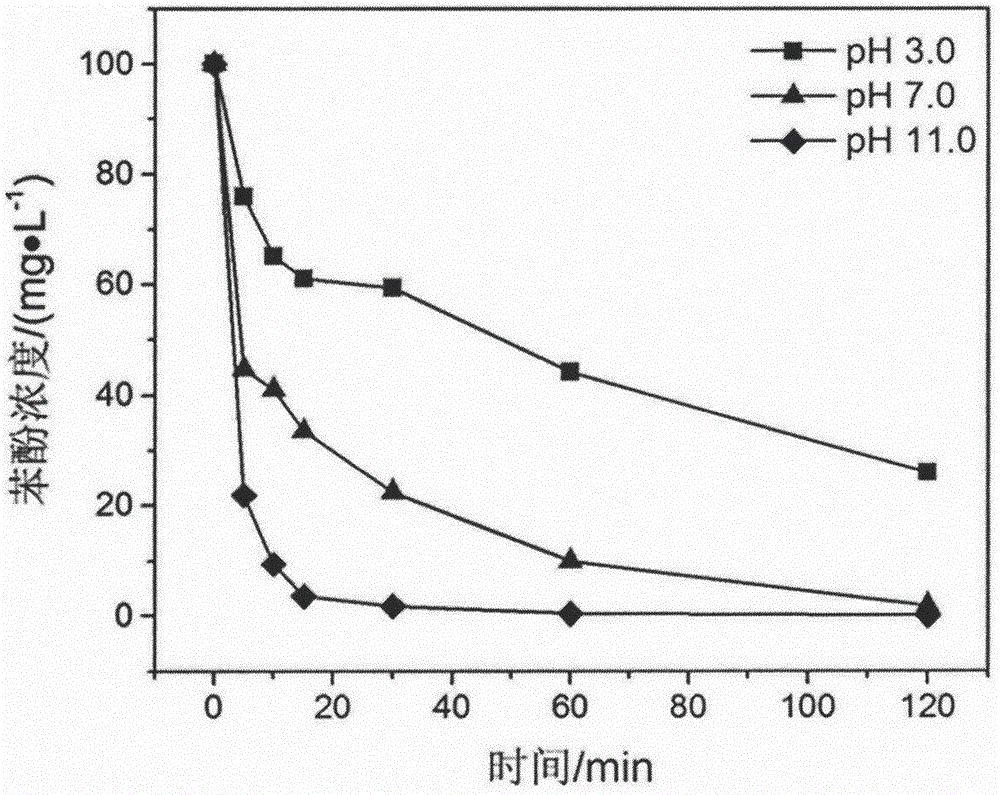

[0031] (7) Weigh 0.1g L -1 Pour the catalyst into a conical flask filled with 120mL of pure water, place it for 12h, and adjust the pH to a specific value when it is to be reacted;

[0032] (8) will contain 15mL 1.0g L -1 of phenol wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com