Method for producing colored glass bottle by centrifugal casting

A centrifugal casting, glass bottle technology, applied in glass forming, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of single color, can not fully meet the production, and have a great impact, and achieve improved quality, high fluidity, and reduced The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

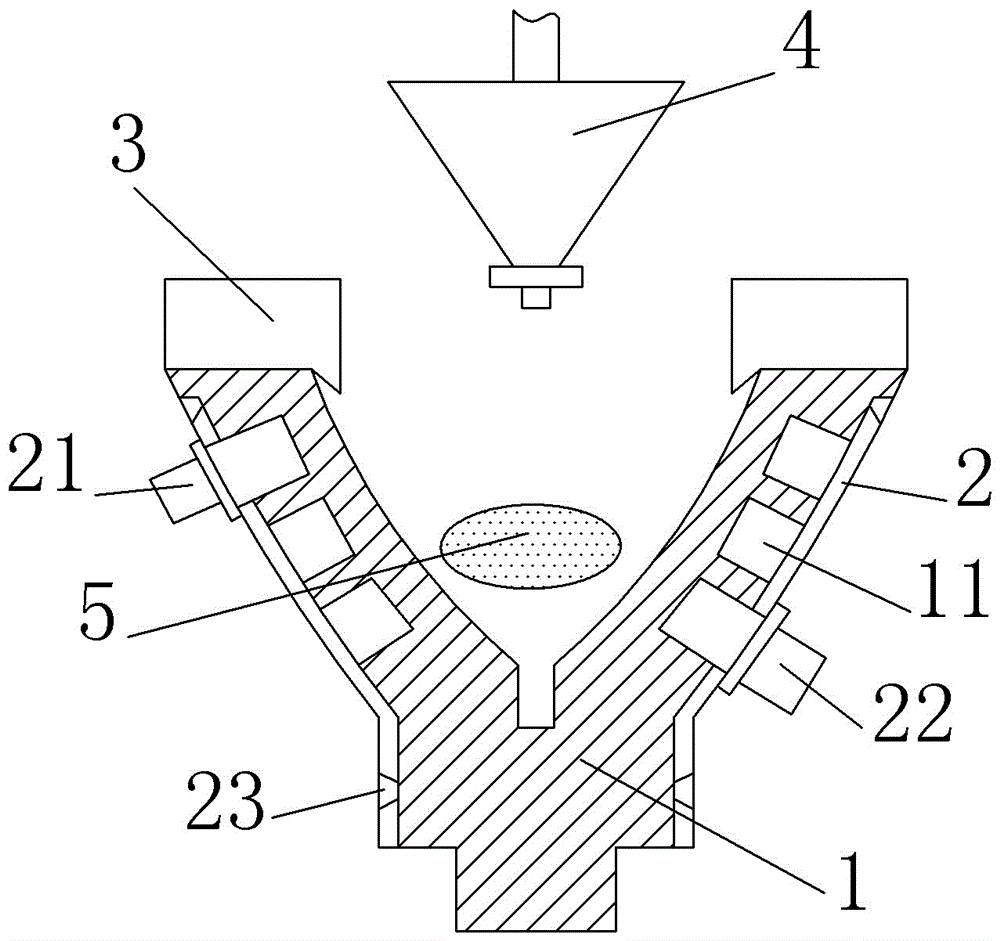

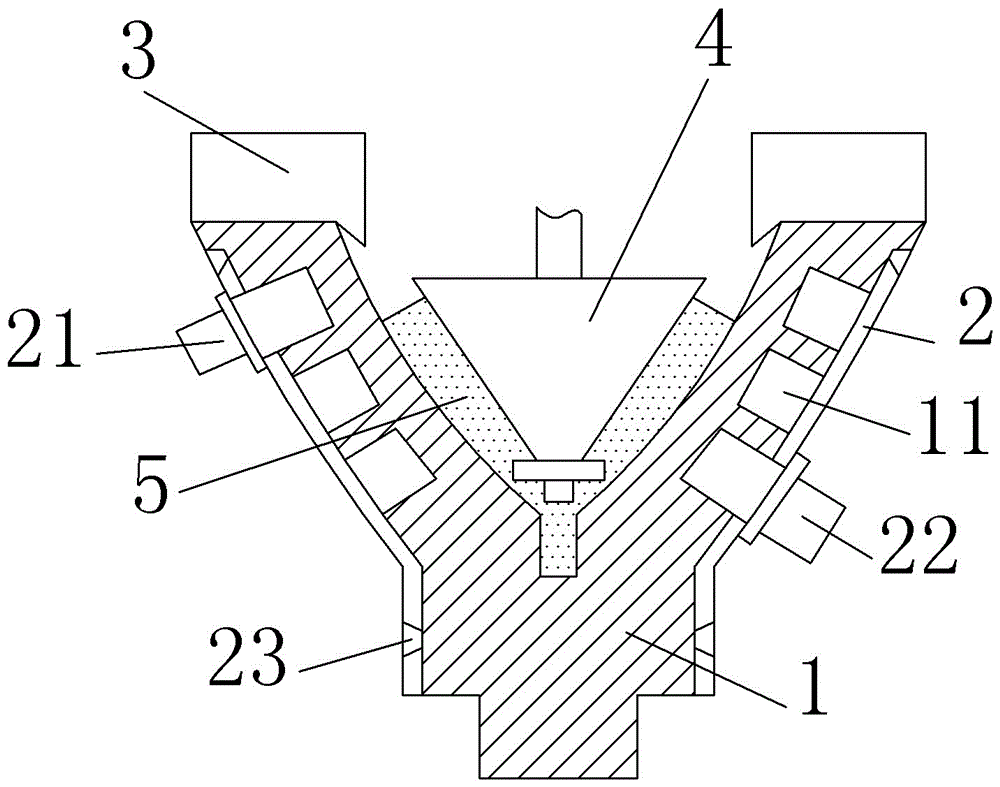

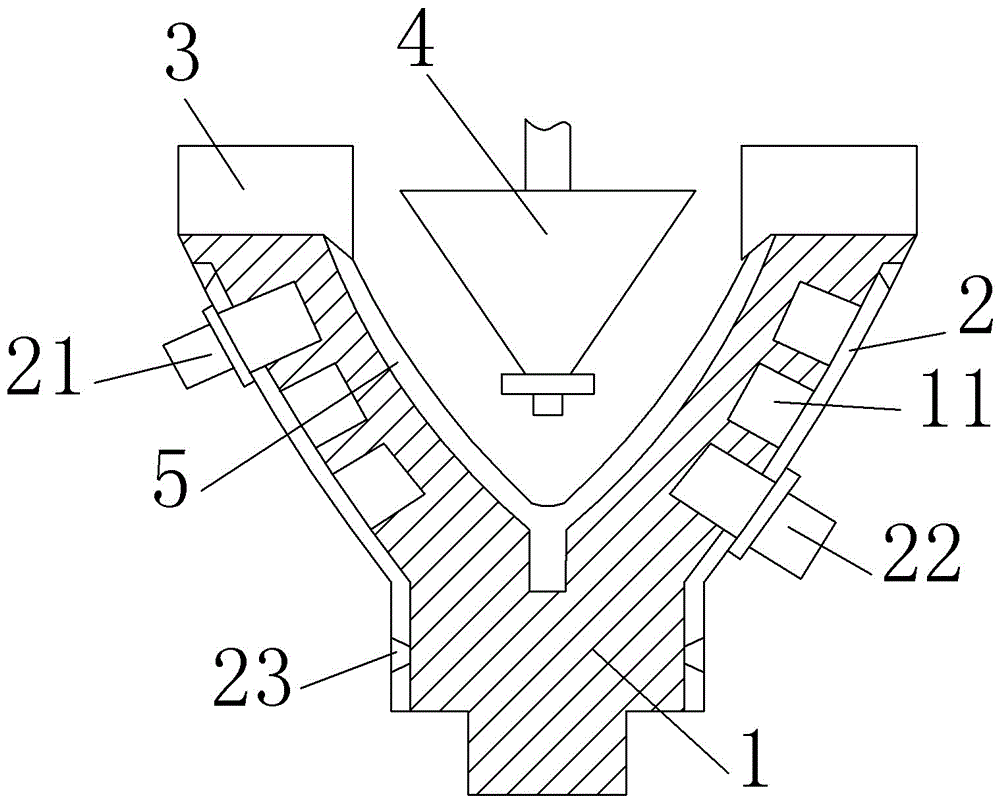

[0027] The reference signs in the drawings of the description include: bottom inner mold 1, cooling water channel 11, bottom outer mold 2, water inlet pipe 21, water outlet pipe 22, welding groove 23, ring mold 3, punch 4, first vertical rod 41 , the second vertical bar 42, the third vertical bar 43, the conical head 44, the water inlet 45, the first drain hole 46, the second drain hole 47, the nut 48, the glass liquid 5.

[0028] A forming method for manufacturing colored glass bottles by centrifugal casting, the method adopts centrifugal casting mold forming, comprising the following steps:

[0029] (1) Install the ring mold on the bottom mold. When the glass liquid is cooled to 800-1000°C and drip into the forming cavity, turn the conical head so that the second drainage hole is staggered from the first drainage hole. Within this temperature range High-quality molten ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap