Pulverized fuel ash light-weight wallboard and preparation method thereof

A lightweight wallboard, fly ash technology, applied in sustainable waste treatment, solid waste management, climate sustainability and other directions, can solve the problems of air pollution, dust generation, biological hazards, etc., achieve good anti-aging performance, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

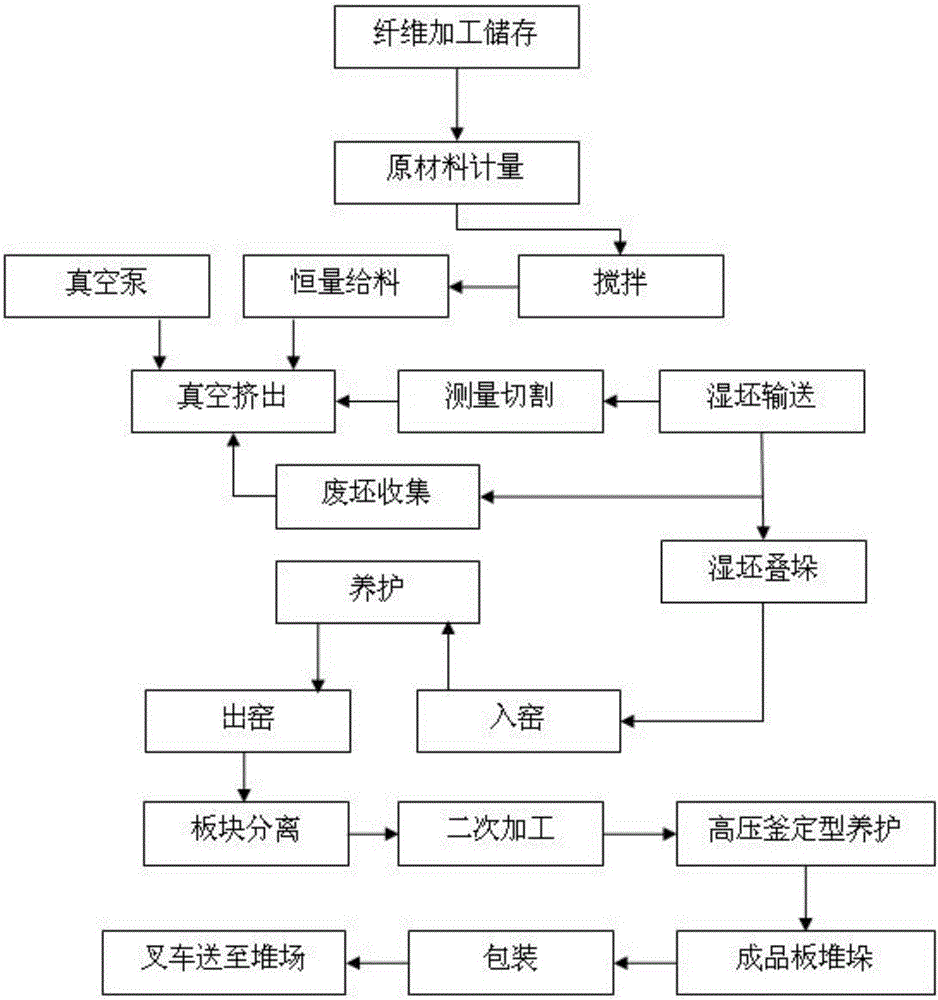

Image

Examples

Embodiment 1

[0020] refer to figure 1 , the fly ash lightweight wallboard of the present invention is calculated in parts by weight. The lightweight wallboard is composed of 70 parts of fly ash, 20 parts of cement, and 5 parts of basalt fiber. The specific preparation method includes the following steps:

[0021] Step 1: carry out dry mixing of fly ash, cement and fibrous material according to the proportion;

[0022] Step 2: The dry mixed material is input into the wet mixer, and an appropriate amount of water is added at the same time for wet mixing;

[0023] Step 3: Transport the material to the extrusion molding machine to extrude and form the wet billet wallboard;

[0024] Step 4: Measure and cut the extruded wet billet wallboard;

[0025] Step 5: Transport the wet wallboard to the steam curing system for 12 to 16 hours. The steam curing system is composed of curing kiln, heating, humidification, temperature measurement, kiln door and control system. The product is kept at a certain...

Embodiment 2

[0029] The fly ash lightweight wallboard of the present invention is calculated in parts by weight. The lightweight wallboard is composed of 70 parts of fly ash, 20 parts of cement, and 5 parts of bamboo fiber. The specific preparation method includes the following steps:

[0030] Step 1: carry out dry mixing of fly ash, cement and fibrous material according to the proportion;

[0031] Step 2: The dry mixed material is input into the wet mixer, and an appropriate amount of water is added at the same time for wet mixing;

[0032] Step 3: Transport the material to the extrusion molding machine to extrude and form the wet billet wallboard;

[0033] Step 4: Measure and cut the extruded wet billet wallboard;

[0034] Step 5: Transport the wet wallboard to the steam curing system for 12 to 16 hours. The steam curing system is composed of curing kiln, heating, humidification, temperature measurement, kiln door and control system. The product is kept at a certain temperature in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com