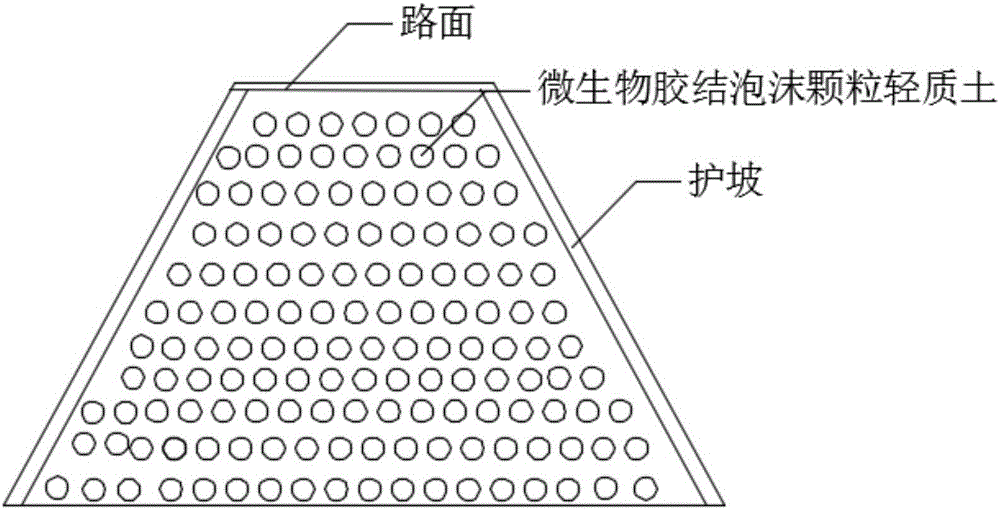

Geotechnical material of microbial granule and production method thereof

A technology of geotechnical materials and foam particles, applied in the field of materials, can solve the problems of difficult reuse of waste materials, difficult construction, high cost of building materials, etc., and achieve the effects of long-distance transportation and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1-1 Preparation of Bacillus pasteurian bacteria liquid:

[0043] 1) Inoculate the culture medium with Bacillus pasteurianum, and culture it in a constant temperature shaker at 30°C and 121r / min for 30-40 hours.

[0044] Each liter of culture medium contains 20g of yeast extract, 25mg of manganese sulfate, 5mg of nickel chloride, 15g of ammonium chloride, and the pH is adjusted to 9-10 with sodium hydroxide.

[0045] 2) Take out the culture solution and concentrate it in a centrifuge at 4°C to make a Bacillus pasteurian bacteria solution.

[0046] The concentration of Pasteurella in the obtained Pasteurella bacteria liquid is 10 8 CFU / mL

[0047] 1-2 A geotechnical material of microbial cemented foam particles, characterized in that it comprises the following raw materials and parts by weight thereof:

[0048] 4.3 parts of foamed plastic particles or fragments;

[0049] 87 parts of calcareous sand;

[0050] 8.7 parts of Bacillus pasteurian bacteria liquid.

[0051]...

Embodiment 2

[0061] 2-1 Preparation of Bacillus pasteurian bacteria liquid:

[0062] 1) Inoculate the culture medium with Bacillus pasteurianum, and culture it in a constant temperature shaker at 30°C and 121r / min for 30-40 hours.

[0063] Each liter of culture medium contains 20g of yeast extract, 25mg of manganese sulfate, 5mg of nickel chloride, 15g of ammonium chloride, and the pH is adjusted to 9-10 with sodium hydroxide.

[0064] 2) Take out the culture solution and concentrate it in a centrifuge at 4°C to make a Bacillus pasteurian bacteria solution.

[0065] The concentration of Pasteurella in the obtained Pasteurella bacteria liquid is 10 9 CFU / mL

[0066] 2-2 A geotechnical material of microbial cemented foam particles, characterized in that it comprises the following raw materials and parts by weight:

[0067] 1.3 parts of foamed plastic particles or fragments;

[0068] Calcareous sand 92.8 parts;

[0069] 6.9 parts of Bacillus pasteurian bacteria liquid.

[0070] The partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com