Metal-organic framework imprinted material and preparation method thereof

A technology of imprinting material and metal frame, which is applied in the field of metal frame imprinting material and its preparation, can solve the problem that the detection trend of organophosphorus pesticide residues cannot be satisfied, and achieves simplified pretreatment process, high environmental friendliness, good dispersibility and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

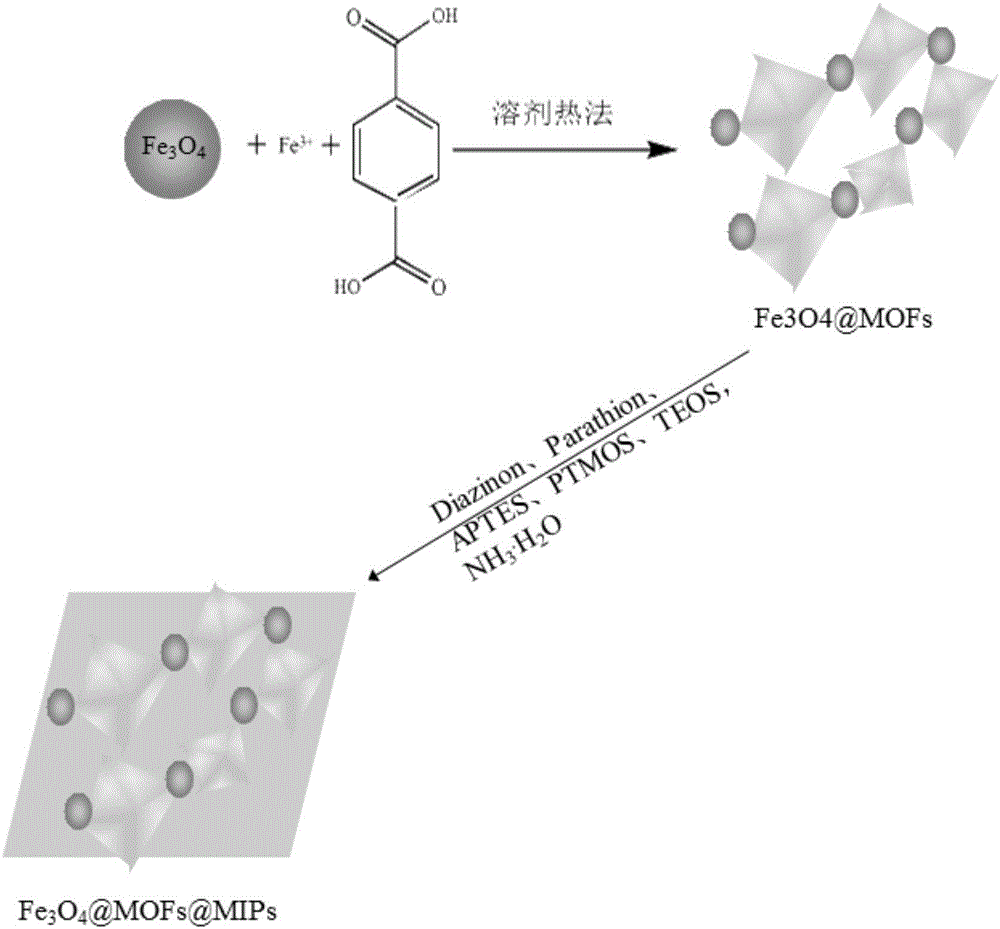

[0020] A method for preparing a metal frame imprinted material provided by an embodiment of the present invention includes the following steps:

[0021] Preparation of magnetic metal organic framework compounds;

[0022] Magnetic Fe 3 o 4 Ultrasonic dispersion of nanoparticles into FeCl-containing 3 Add the DMF solution containing terephthalic acid to the DMF solution of terephthalic acid. After the ultrasonic dispersion is uniform, the mixed solution is placed in the inner liner of the reaction kettle and reacted at 110-150°C for 16-24 hours. After the reaction is completed, the reaction product is washed with absolute ethanol to remove ethanol-soluble matter in the reaction product, and dried at 55-65° C. for 10-14 hours to obtain a magnetic metal organic framework compound. Because FeCl 3 It is easy to absorb water and has strong water absorption. It can absorb moisture in the air and deliquescence, so FeCl 3 Optional FeCl 3 ·6H 2 O. Preferably, the magnetic Fe 3 o...

Embodiment 1

[0035] Please refer to figure 1 , this embodiment provides a metal frame imprinted material, which is prepared by the following steps:

[0036] 4mmolFeCl 3 , 2mmolFeCl 2 and 100 mL of deionized water were placed in a 250 mL three-necked flask, mechanically stirred for 20 min under nitrogen protection at 70°C, and then 5 mL of ammonia water was added. Cool to 20°C after the reaction, and collect magnetic Fe with an external magnetic field 3 o 4 nanoparticles and washed with ultrapure water and ethanol.

[0037] 50mg magnetic Fe 3 o 4 Nanoparticles were ultrasonically dispersed to contain 2.5 g of FeCl 3 ·6H 2 To the DMF solution of O, add the DMF solution containing 0.75g of terephthalic acid. The DMF solution is 50mL. After the reaction is finished, wash with absolute ethanol and dry at 55°C for 10 hours to obtain a magnetic metal organic framework compound.

[0038] Ultrasonic dispersion of 100 mg of magnetic metal-organic framework compound in 10 mL of acetonitrile...

Embodiment 2

[0040] Please refer to figure 1 , this embodiment provides a metal frame imprinted material, which is prepared by the following steps:

[0041] 6mmolFeCl 3 ·6H 2 O, 2.5 mmol FeCl 2 4H 2 O and 100 mL of deionized water were placed in a 250 mL three-necked flask, mechanically stirred for 30 min under nitrogen protection at 80°C, and then 5 mL of ammonia water was added. Cool to 25°C after the reaction, and collect magnetic Fe with an external magnetic field 3 o 4 nanoparticles and washed with ultrapure water and ethanol.

[0042] 75mg magnetic Fe 3 o 4 Nanoparticles were ultrasonically dispersed to contain 3.5 g of FeCl 3 ·6H 2 To the DMF solution of O, add the DMF solution containing 1.2g of terephthalic acid, the DMF solution is 100mL, after the ultrasonic dispersion is uniform, the mixed solution is placed in the inner liner of the reaction kettle, and reacted at 130°C for 20h. After the reaction is finished, wash with absolute ethanol and dry at 60° C. for 12 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com