Odorless automotive upholstery material and preparation method thereof

A technology for automobile interior parts and odorless, which is applied in the field of automobile interior parts materials and its preparation to achieve the effects of light weight, low odor and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

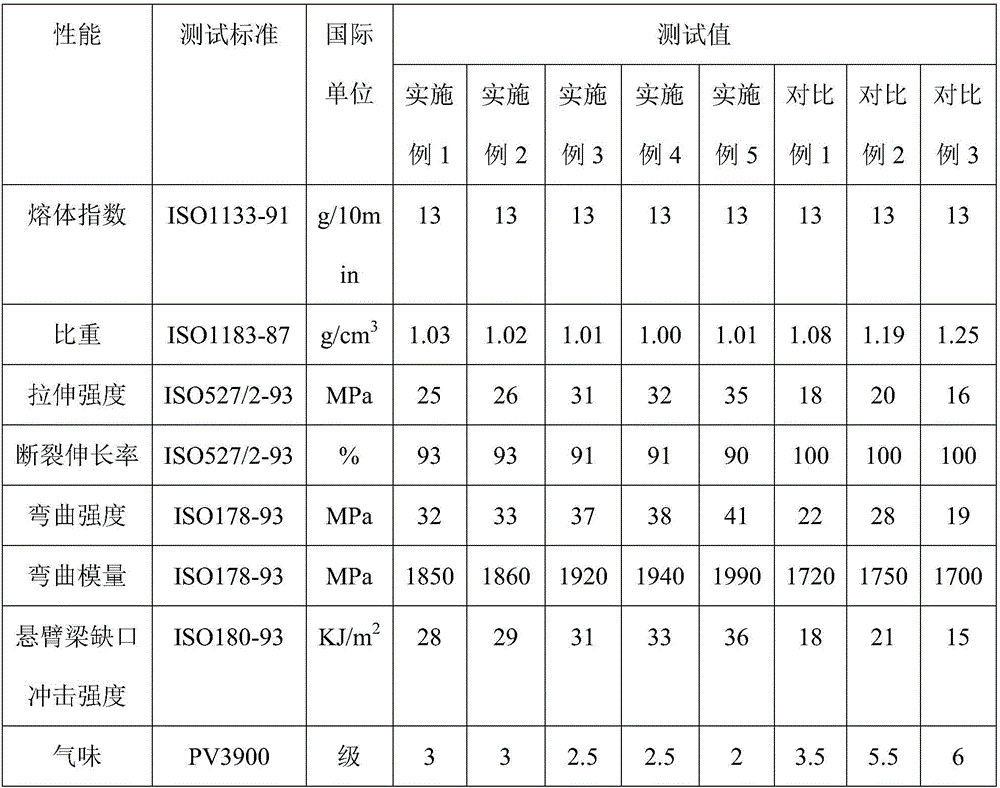

Examples

Embodiment 1

[0016] In the embodiment of the present invention, an odorless automotive interior trim material is composed of the following raw materials in parts by weight: 45 parts of polypropylene, 11 parts of polytetrahydrofuran ether glycol, 3 parts of N-alkyl-2-pyrrolidone, 5 parts of nano silver ion, 15 parts of cyanoethyl cellulose, and 1 part of yttrium oxide.

[0017] Mix polytetrahydrofuran ether glycol with 3.8 times its mass of 65% ethanol to prepare polytetrahydrofuran ether glycol solution; mix N-alkyl-2-pyrrolidone with 1.6 times its mass of isopropanol to prepare N-alkyl -2-pyrrolidone solution. The mixture A is obtained by mixing and grinding nano-silver ions and yttrium oxide, and passing through a 120-mesh sieve. Mix and grind polypropylene and cyanoethyl cellulose, pass through a 150-mesh sieve, put it into a polytetrafluoroethylene reaction kettle, then add polytetrahydrofuran ether glycol solution, seal it, and heat and stir it at 114°C for 35 minutes. Then add mixt...

Embodiment 2

[0019] In the embodiment of the present invention, an odorless automotive interior trim material is composed of the following raw materials in parts by weight: 55 parts of polypropylene, 19 parts of polytetrahydrofuran ether glycol, 7 parts of N-alkyl-2-pyrrolidone, 12 parts of nano-silver ions, 23 parts of cyanoethyl cellulose, and 5 parts of yttrium oxide.

[0020] Mix polytetrahydrofuran ether glycol with 3.8 times its mass of 65% ethanol to prepare polytetrahydrofuran ether glycol solution; mix N-alkyl-2-pyrrolidone with 1.6 times its mass of isopropanol to prepare N-alkyl -2-pyrrolidone solution. The mixture A is obtained by mixing and grinding nano-silver ions and yttrium oxide, and passing through a 120-mesh sieve. Mix and grind polypropylene and cyanoethyl cellulose, pass through a 150-mesh sieve, put it into a polytetrafluoroethylene reaction kettle, then add polytetrahydrofuran ether glycol solution, seal it, and heat and stir it at 114°C for 40 minutes. Then add m...

Embodiment 3

[0022] In the embodiment of the present invention, an odorless automotive interior trim material is composed of the following raw materials in parts by weight: 48 parts of polypropylene, 13 parts of polytetrahydrofuran ether glycol, 4 parts of N-alkyl-2-pyrrolidone, 7 parts of nano-silver ions, 17 parts of cyanoethyl cellulose, and 2 parts of yttrium oxide.

[0023] Mix polytetrahydrofuran ether glycol with 3.8 times its mass of 65% ethanol to prepare polytetrahydrofuran ether glycol solution; mix N-alkyl-2-pyrrolidone with 1.6 times its mass of isopropanol to prepare N-alkyl -2-pyrrolidone solution. The mixture A is obtained by mixing and grinding nano-silver ions and yttrium oxide, and passing through a 120-mesh sieve. Mix and grind polypropylene and cyanoethyl cellulose, pass through a 150-mesh sieve, put it into a polytetrafluoroethylene reaction kettle, then add polytetrahydrofuran ether glycol solution, seal it, and heat and stir it at 114°C for 38 minutes. Then add mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com