Low dielectric constant liquid crystal polyester resin compound and preparation method thereof

A technology of resin composites and low dielectric constants, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of poor dielectric properties of liquid crystal polyester resin composites, and achieve the reduction of dielectric constant and good phase The effect of capacitive and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] And, an embodiment of the present invention provides a method for preparing a low dielectric constant liquid crystal polyester resin compound, comprising the following steps:

[0039] S01. Weigh each component according to the formula of the above-mentioned low dielectric constant liquid crystal polyester resin compound, wherein the additive is ultra-high molecular weight polyethylene, and the number-average molecular weight of the ultra-high molecular weight polyethylene is 1.15 million- 5.9 million;

[0040] S02. Drying the wholly aromatic liquid crystal polyester resin, additives, and fillers;

[0041] S03. Mix the dried additives and fillers uniformly to obtain a mixture;

[0042] S04. Feed the mixture and the wholly aromatic liquid crystal polyester resin, melt extrude through a twin-screw extruder, draw, cool, and granulate.

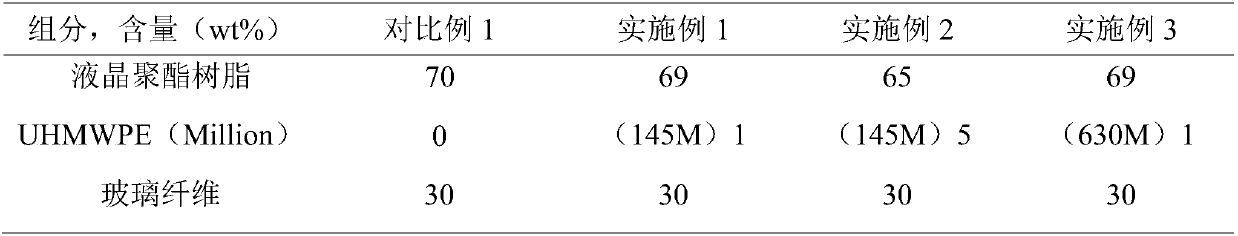

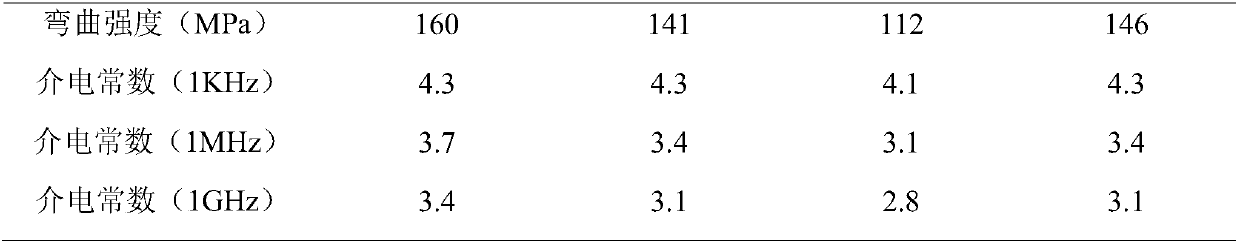

[0043] Specifically, in the above-mentioned step S01, the formulation of the low dielectric constant liquid crystal polyester resin compo...

Embodiment 1

[0056] A low dielectric constant liquid crystal polyester resin compound, containing the components shown in Table 1, Example 1, in weight percent.

[0057] The preparation method of described low dielectric constant liquid crystal polyester resin compound, comprises the following steps:

[0058] S11. Weigh each component according to the formula of the above-mentioned wholly aromatic liquid crystal polyester resin compound;

[0059] S12. Drying the wholly aromatic liquid crystal polyester resin, additives, and fillers at 130° C. for 4 hours;

[0060] S13. Put the dried additives and fillers into an automatic mixer and mix evenly to obtain a mixture;

[0061] S14. Feed the mixture and the wholly aromatic liquid crystal polyester resin, melt extrude through a twin-screw extruder, draw, cool, and granulate.

Embodiment 2

[0063] A low dielectric constant liquid crystal polyester resin compound, containing the components shown in Table 1, Example 2 in weight percentage.

[0064] The preparation method of the low dielectric constant liquid crystal polyester resin compound is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com