Coating for protecting aerostat capsule material and preparation method and application thereof

A technology of aerostats and coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low helium barrier properties, low helium barrier rate, poor UV aging resistance, etc., to improve helium gas barrier properties , no surface defects, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

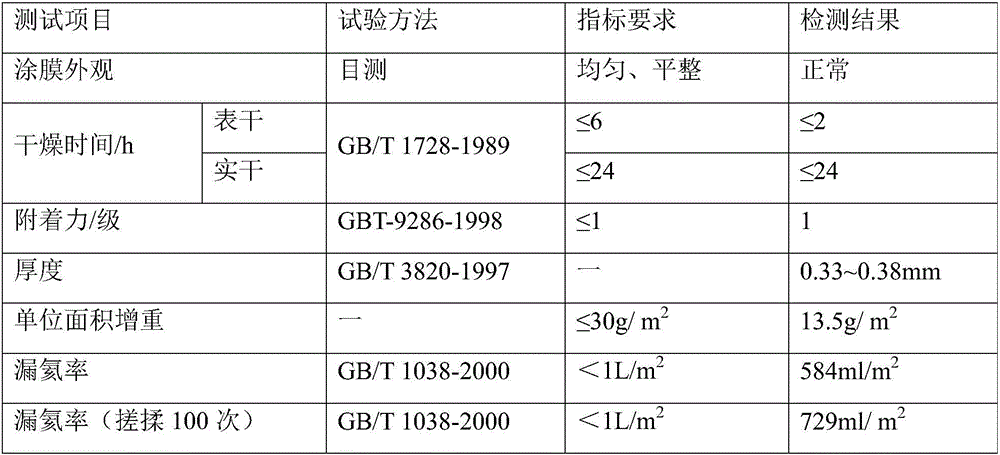

Embodiment 1

[0036] The NY-35 polyurethane resin of Yantai Huada Chemical Group Co., Ltd. was used to prepare the protective coating for the aerostat capsule material, and it was coated on the capsule substrate of 20×20mm with a 6 μm coating wire bar, and the properties were tested. test.

[0037] Aerostat capsule material protective coating:

[0038] It is prepared by mixing component A and component B, wherein the mass content of component B is 12.5% of that of component A, and the details of each component are as follows:

[0039] A component: polyurethane resin: 50 parts;

[0040] Titanium dioxide: 12 parts;

[0041] Defoamer: 1 part;

[0042] Dispersant: 1 part;

[0043] Solvent: 30 parts;

[0044] B component: curing agent.

[0045] Preparation method of aerostat capsule material protective coating:

[0046] (1) Add 50 parts of polyurethane resin to the batching tank, and add 12 parts of titanium dioxide, 1 part of dispersant, 1 part of defoamer, and 30 parts of solvent and ...

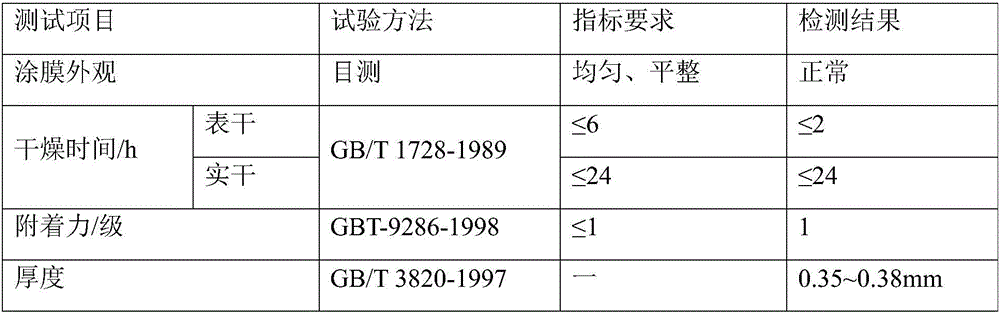

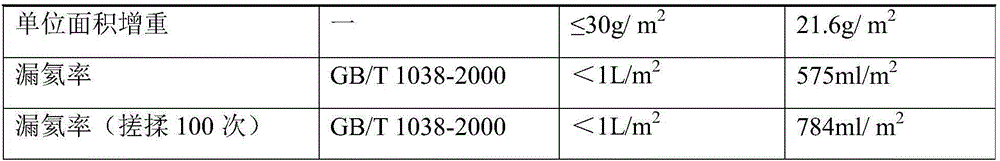

Embodiment 2

[0055] Similarly, the NY-35 polyurethane resin of Yantai Huada Chemical Group Co., Ltd. was used to prepare the protective coating for the aerostat capsule material, and coated it on the capsule substrate of 20×20mm with a 6 μm coating wire bar , for performance testing.

[0056] Aerostat capsule material protective coating:

[0057] It is prepared by mixing component A and component B, wherein the mass content of component B is 12.5% of that of component A, and the details of each component are as follows:

[0058] A component: polyurethane resin: 50 parts;

[0059] Titanium dioxide: 20 parts;

[0060] Defoamer: 1 part;

[0061] Dispersant: 1 part;

[0062] Solvent: 30 parts;

[0063] B component: curing agent;

[0064] Preparation method of aerostat capsule material protective coating:

[0065] (1) Add 50 parts of polyurethane resin to the batching tank, and add 20 parts of titanium dioxide, 1 part of dispersant, 1 part of defoamer, and 30 parts of solvent and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com