Concentrating and tar removing method of biomass gasification liquid (bamboo vinegar)

A processing method and technology of bamboo vinegar liquid are applied in the processing field of concentrating and detaring, and can solve problems such as affecting product promotion, bamboo vinegar liquid cannot be formed into large-tonnage consumer goods, and bamboo vinegar liquid has low content of active ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

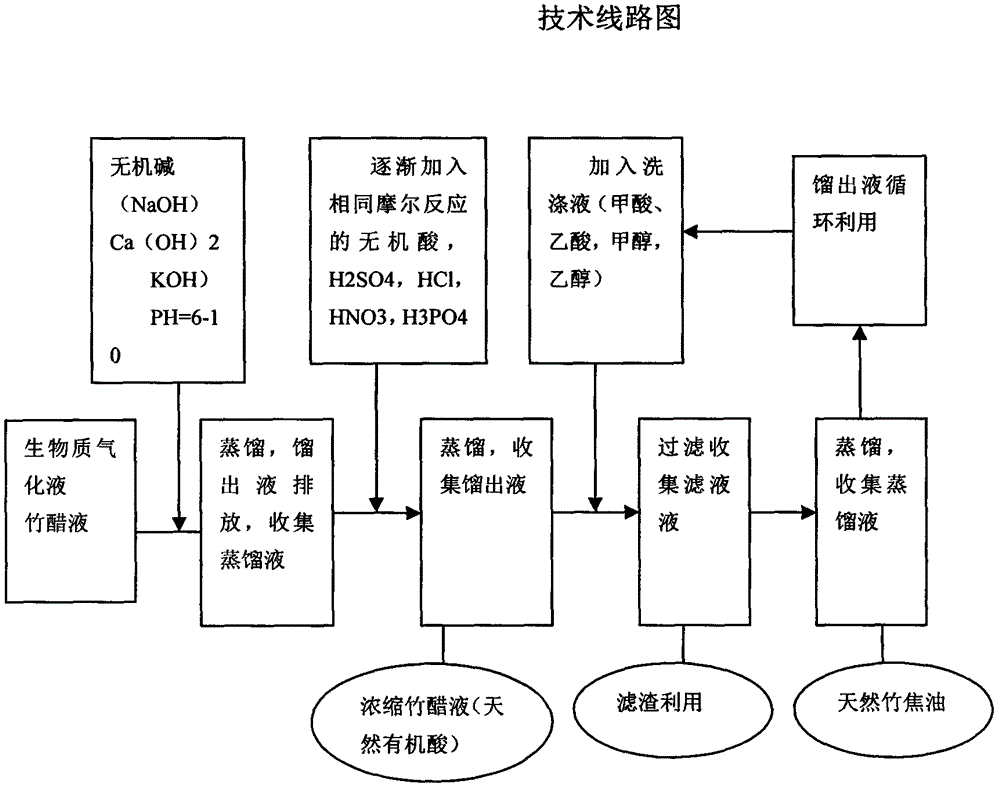

Method used

Image

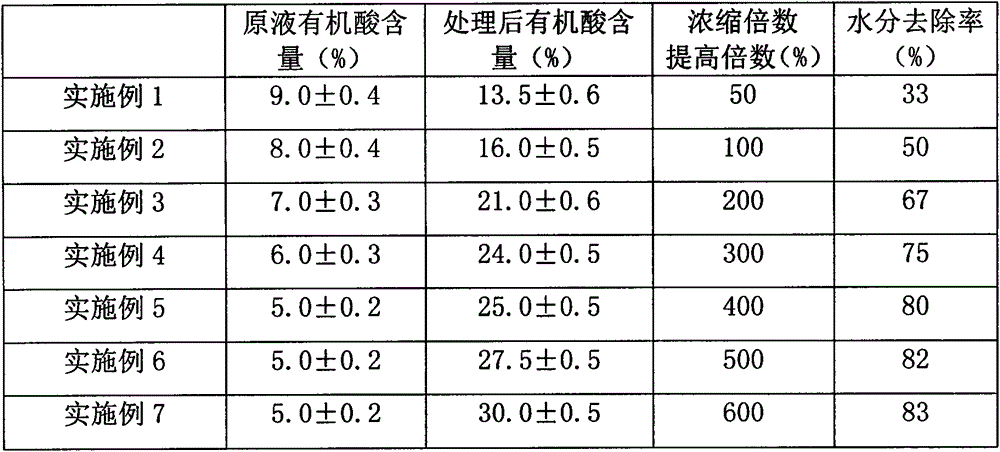

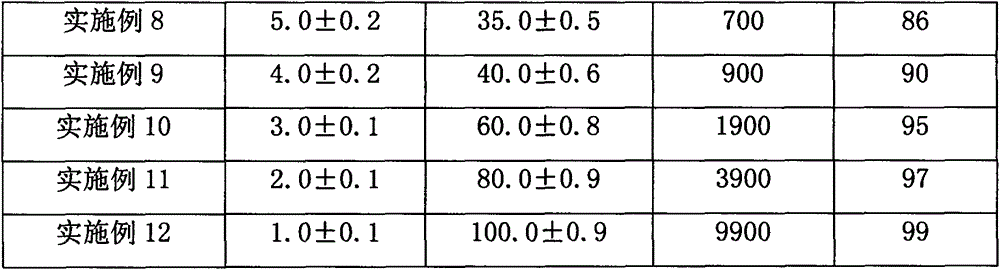

Examples

example 1

[0041] 1) Put 100 parts of bamboo vinegar into the enamel reaction kettle, then slowly add Ca(OH)2 (or CaO) into it and stir to dissolve completely until PH=6, record the amount of inorganic alkali added as 4 parts; 2) Distillation atmospheric pressure distillation for the first time, till 10% that distillate accounts for the ratio of bamboo vinegar liquid is 10 parts, distillate is discharged as waste water; The inorganic acid HCl (10.665 parts (37% hydrochloric acid aqueous solution), the calculation method is calculated according to the following method

[0042] Ca(OH)2+2HCl=CaCl2+2H2O;

[0043] 74 73

[0044] 4 x = ? X=73*4 parts / 74=3.946 parts (effective content)=10.665 parts (37% hydrochloric acid aqueous solution)

[0045] 2) The second distillation is at normal pressure until the distillation is complete (i.e. no distillate is produced), and the distillate is collected, which is concentrated bamboo vinegar.

[0046] 3) Washing and filtering, that is, distilling the...

example 2

[0049]1) Put 100 parts of bamboo vinegar into the enamel reaction kettle, then slowly add NaOH therein and stir to dissolve completely until PH=7, record the amount of adding inorganic alkali as 4 parts; 2) Distill for the first time at atmospheric pressure, 20% of the ratio of the bamboo vinegar liquid that the distillate accounts for is 20 parts, and the distillate is discharged as waste water; 3) acidification reaction, under the situation of constantly stirring, gradually adds the mineral acid HCl (9.865 parts of ( 37% hydrochloric acid aqueous solution), the calculation method is calculated according to the following method

[0050] NaOH+HCl=NaCl+H2O

[0051] 40 36.5

[0052] 4 x = ? X=36.5*4 parts / 40=3.65 parts (effective content)=9.865 parts (37% hydrochloric acid aqueous solution)

[0053] 2) The second distillation is at normal pressure until the distillation is complete (i.e. no distillate is produced), and the distillate is collected, which is concentrated bamboo...

example 3

[0057] 1) Put 100 parts of bamboo vinegar into the enamel reaction kettle, then slowly add NaOH therein and stir to dissolve completely until PH=7, record the amount of adding inorganic alkali as 4 parts; 2) Distill for the first time at atmospheric pressure, 30% that distillate accounts for the ratio of bamboo vinegar liquid till 30 parts, distillate is discharged as waste water; 3) acidification reaction, under the situation of constantly stirring, gradually add the inorganic acid HCl (7.046 parts of 37% hydrochloric acid aqueous solution), the calculation method is calculated according to the following method

[0058] KOH+HCl=KCl+H2O

[0059] 56 36.5

[0060] 4 x = ? X=36.5*4 parts / 56=2.61 parts (effective content)=7.046 parts (37% hydrochloric acid aqueous solution)

[0061] 2) The second distillation is at normal pressure until the distillation is complete (i.e. no distillate is produced), and the distillate is collected, which is concentrated bamboo vinegar.

[0062]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com