Mutant short-chain dehydrogenase, recombinant expression vector, genetic engineering bacterium and application

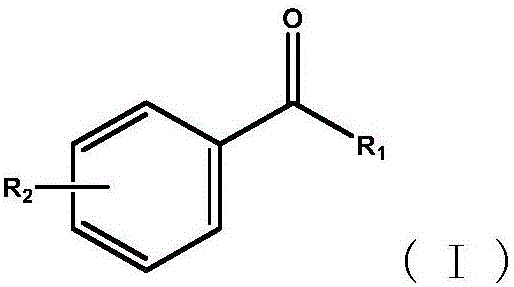

A technology of short-chain dehydrogenase and genetically engineered bacteria, which is applied in the application field of preparing optically pure chiral alcohol, can solve the problem that the catalytic activity of short-chain dehydrogenase cannot meet the requirements of industrial production, and achieves good development prospects for industrial application. , easy preparation, wide substrate adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the construction of mutant

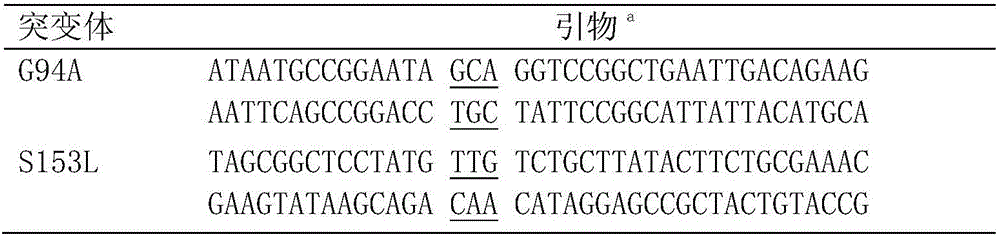

[0038] The pET-30a recombinant plasmid containing the short-chain dehydrogenase EbSDR8 gene was amplified using the QuickChangeTM method (Stratagene, La Jolla, CA) using the oligonucleotide fragment containing the mutation point as a primer (Table 1).

[0039] Table 1 Mutant construction primers

[0040]

[0041] a Mutation sites are underlined

[0042] PCR reaction system: 5×PrimerSTAR buffer (Mg2+plus), 5 μL; dNTPs (2.5 mM each), 2.0 μL; upstream primer (10 μM), 1.0 μL; downstream primer (10 μM), 1.0 μL; recombinant plasmid template, 15 ng; PrimerSTARpolymeraseTM HS (2.5U / μL), 0.5 μL; add ddH2O to a total volume of 25 μL.

[0043] PCR program: (1) 98°C, 1min; (2) 98°C, 10s; (3) 55°C, 10s; (4) 72°C, 7min. Steps (2)-(4) were cycled 20 times and then cooled to 4°C.

[0044] After the PCR product is washed, it is digested with the restriction endonuclease DpnI that specifically recognizes the methylation site to degrade t...

Embodiment 2

[0046] Example 2: Induced expression of short-chain dehydrogenase mutants

[0047] The engineered bacteria constructed in Example 1 were inoculated into LB liquid medium containing 50 μg / mL kanamycin, cultivated overnight at 37° C., and then inoculated into 50 μg / mL kanamycin containing 50 μg / mL kanamycin with 1% inoculum size (v / v). In 50mL LB medium, culture at 37°C and 200rpm until the cell concentration OD600 to about 0.6, add IPTG with a final concentration of 0.1mM, induce culture at 26°C for 6h, collect the cells by centrifugation at 4°C and 8000rpm for 10min, and store at -80 Store at ℃ for later use.

Embodiment 3

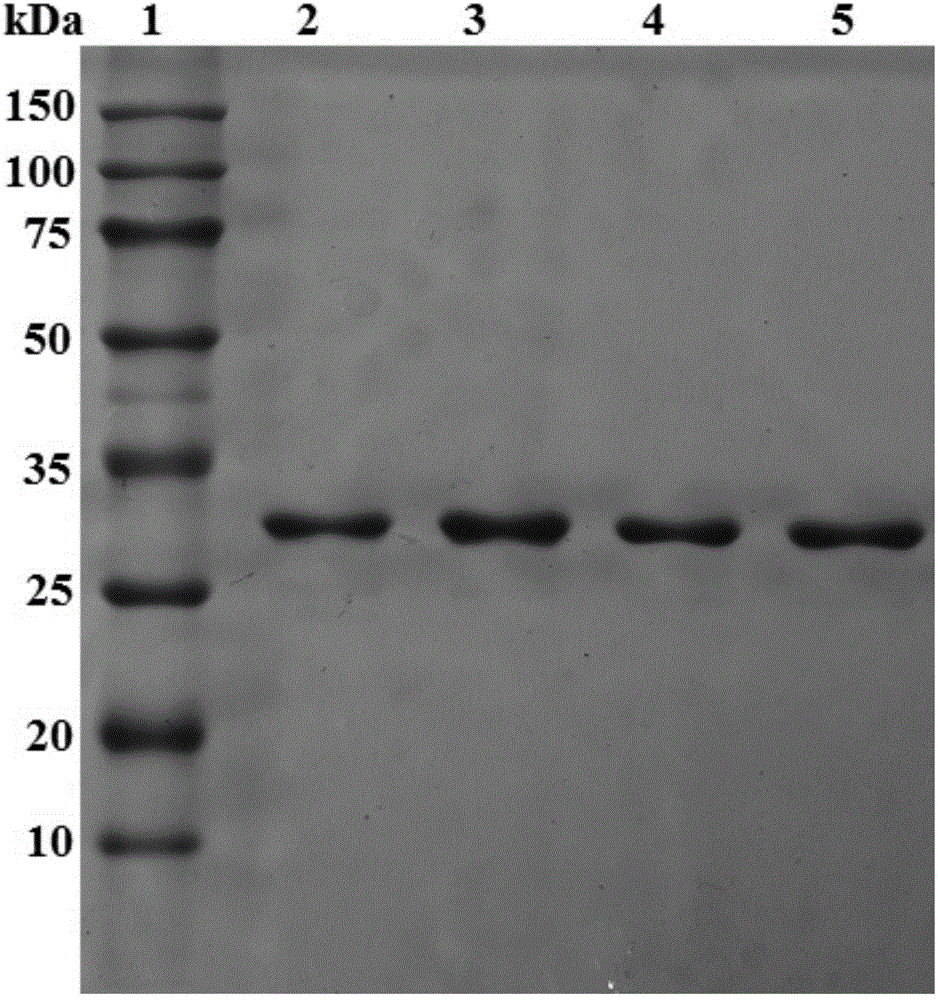

[0048] Embodiment 3: Separation and purification of short-chain dehydrogenase mutants

[0049] The thalli cells that embodiment 2 collects are suspended in 10mL Na 2 HPO 4 -NaH 2 PO 4 In buffer solution (100mM, pH 8.0), shake well and then crush under ultrasonic wave (effective time 8min). The broken liquid was centrifuged at 12,000 rpm for 10 min to remove cell debris, and the supernatant (crude enzyme liquid) was collected for subsequent separation and purification of the enzyme. The purification column is Ni-NTA, and the column volume is 5mL. First equilibrate the Ni-NTA column with loading equilibration buffer (20mM sodium phosphate, 500mM NaCl and 20mM imidazole, pH 7.4), and load the crude enzyme at a rate of 5mL / min. solution, eluted with loading equilibration buffer to remove unadsorbed protein, and finally eluted with elution buffer (20mMT sodium phosphate, 500mM NaCl and 500mM imidazole, pH 7.4) to collect the target protein. The enzyme liquid is desalted with H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com