A method and application of fermentative production of glycyrrhetinic acid monoglucuronate

A technology of glycyrrhetinic acid aldehyde and glucose, applied in the field of bioengineering, can solve the problems of low yield, inability to meet the needs of industrial production, and many by-products, and achieve the effects of low cost, easy operation, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Each L of seed culture medium contains: peptone 5g, glucose 10g, potassium dihydrogen phosphate 1g, magnesium sulfate 0.4g.

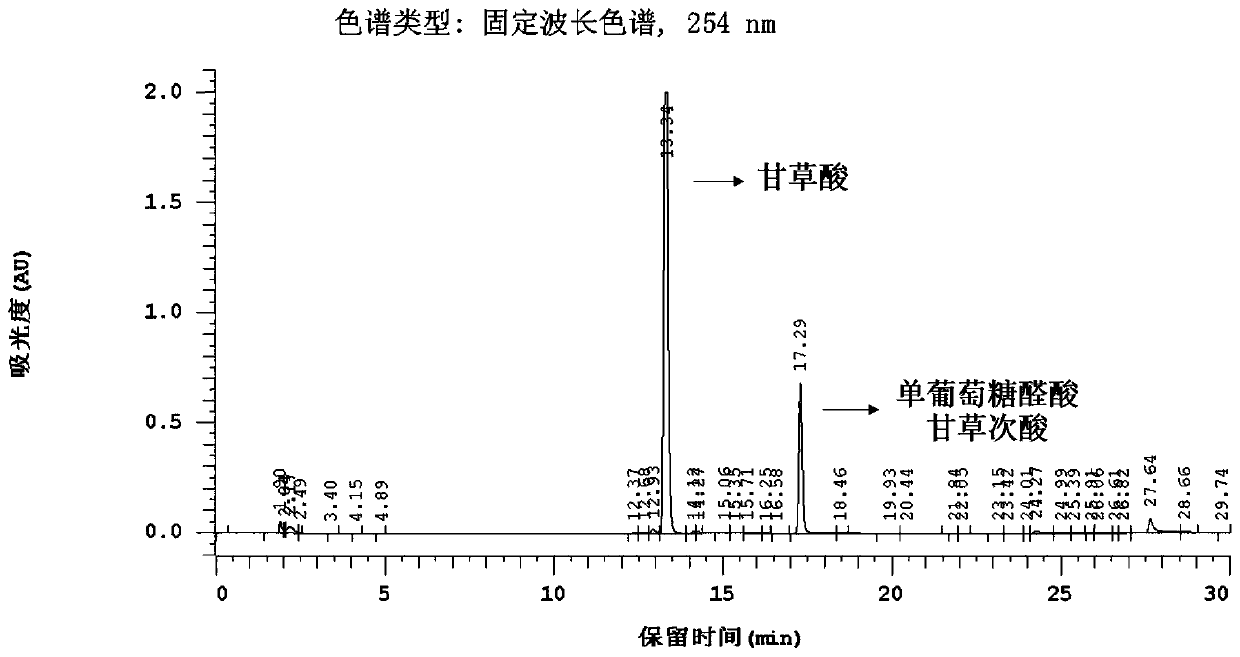

[0020] Each L of fermentation medium contains: glycyrrhizic acid 5g, sodium nitrate 3g, potassium dihydrogen phosphate 2g, magnesium sulfate 1g, ferrous sulfate 0.01g.

[0021] The basket-shaped fungus (Talaromyces sp) was inoculated into the seed medium, and cultured at 25-40° C. for 36-48 hours. Transfer to the fermentation medium with sodium nitrate as the nitrogen source according to the volume, control the initial pH 4.5-6.5, ferment at 25-37°C for 120-144h, control the final concentration of 5g / L-glycyrrhizic acid as carbon source and inducer.

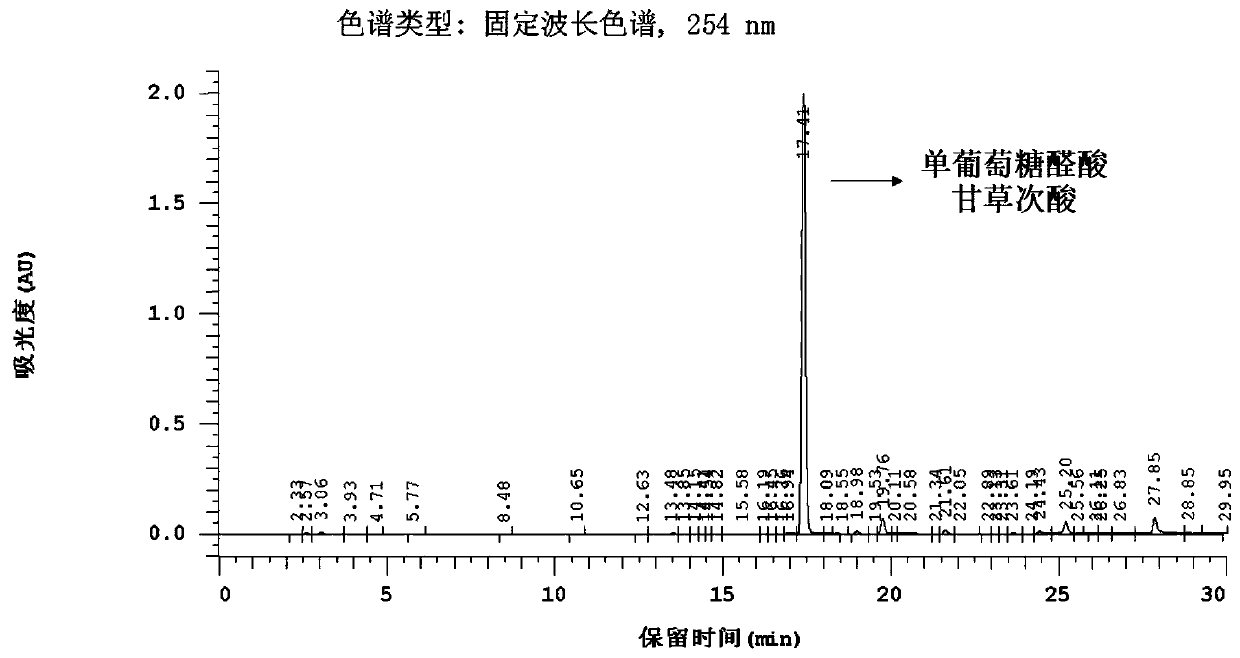

[0022] Detect the output, purity and conversion rate of the target product in the fermentation broth after the fermentation is finished, and the results are as follows: figure 1 Shown, retention time is that the product GAMG output of 16.91 reaches 4.05g / L, productive rate is 88.00%, and this by-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com