Method for producing glycyrrhetinic acid monoglucuronide by fermentation, and application

A technology of glycyrrhizic acid and glycyrrhizic acid, applied in the field of bioengineering, can solve the problems of inability to meet industrial production requirements, many by-products, low yield and the like, and achieve the effects of low cost, short production cycle and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Each L of seed culture medium contains: peptone 5g, glucose 10g, potassium dihydrogen phosphate 1g, magnesium sulfate 0.4g.

[0020] Each L of fermentation medium contains: glycyrrhizic acid 5g, sodium nitrate 3g, potassium dihydrogen phosphate 2g, magnesium sulfate 1g, ferrous sulfate 0.01g.

[0021] The basket-shaped fungus (Talaromyces sp) was inoculated into the seed medium, and cultured at 25-40° C. for 36-48 hours. Transfer to the fermentation medium with sodium nitrate as the nitrogen source according to the volume, control the initial pH 4.5-6.5, ferment at 25-37°C for 120-144h, control the final concentration of 5g / L-glycyrrhizic acid as a carbon source and inducer.

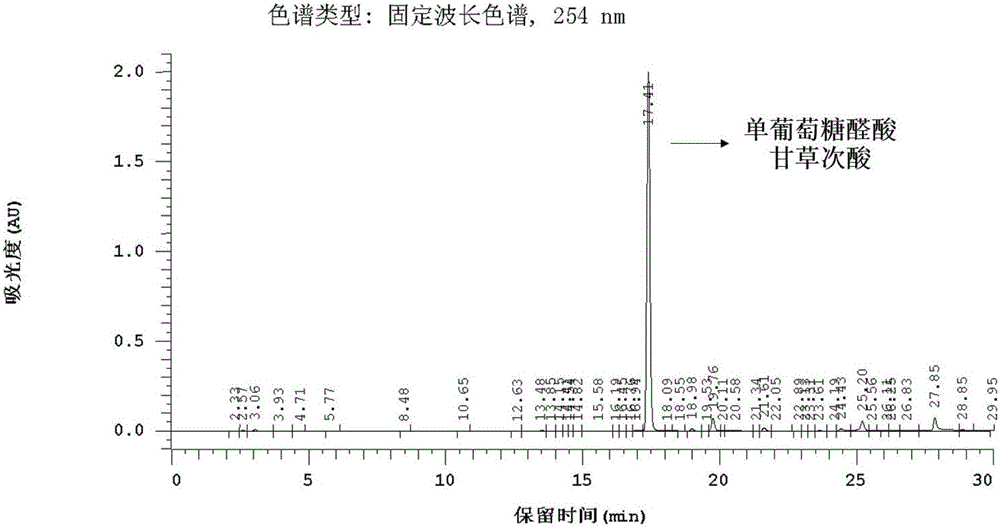

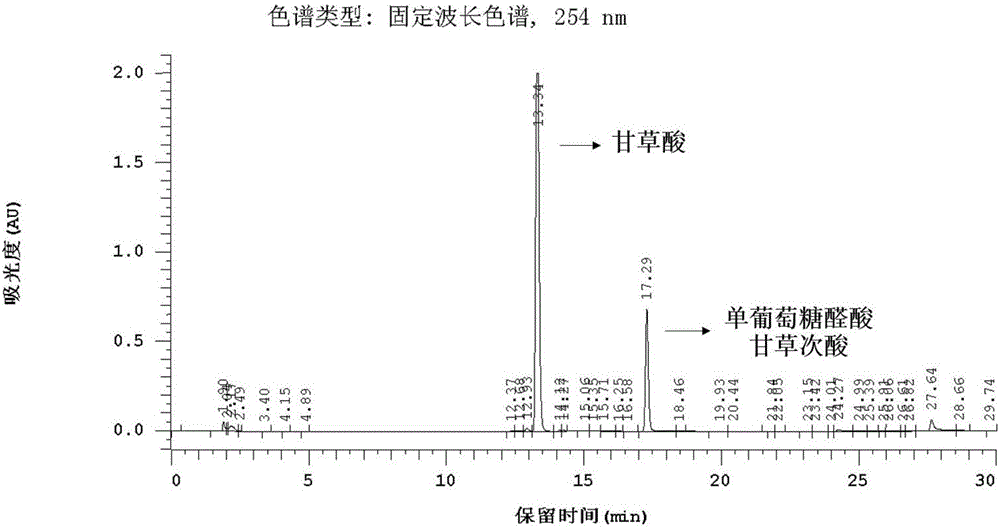

[0022] Detect the output, purity and conversion rate of the target product in the fermentation broth after the fermentation is finished, and the results are as follows: figure 1 Shown, retention time is that the product GAMG output of 16.91 reaches 4.05g / L, and productive rate is 88.00%, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com