Two-way deformable shape memory alloy bump and manufacturing method thereof

A technology of memory alloy and memory alloy plate, which is applied in the field of material bending and deformation, can solve the problems of complex driving mechanism, complex processing technology, and low surface accuracy, and achieve simple manufacturing process, high surface accuracy, and good fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

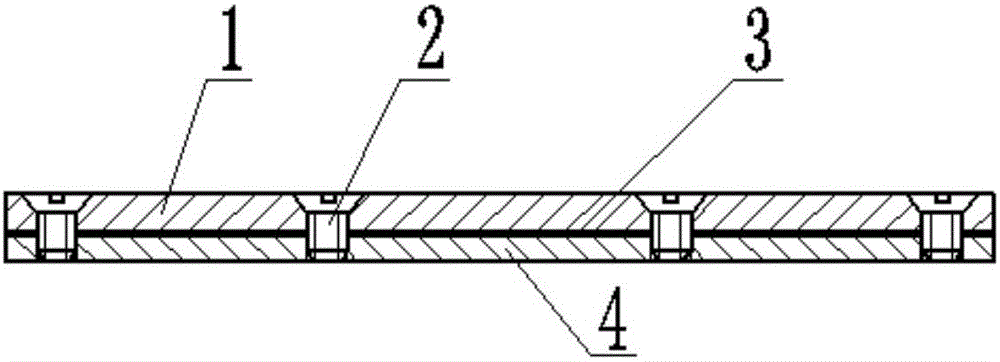

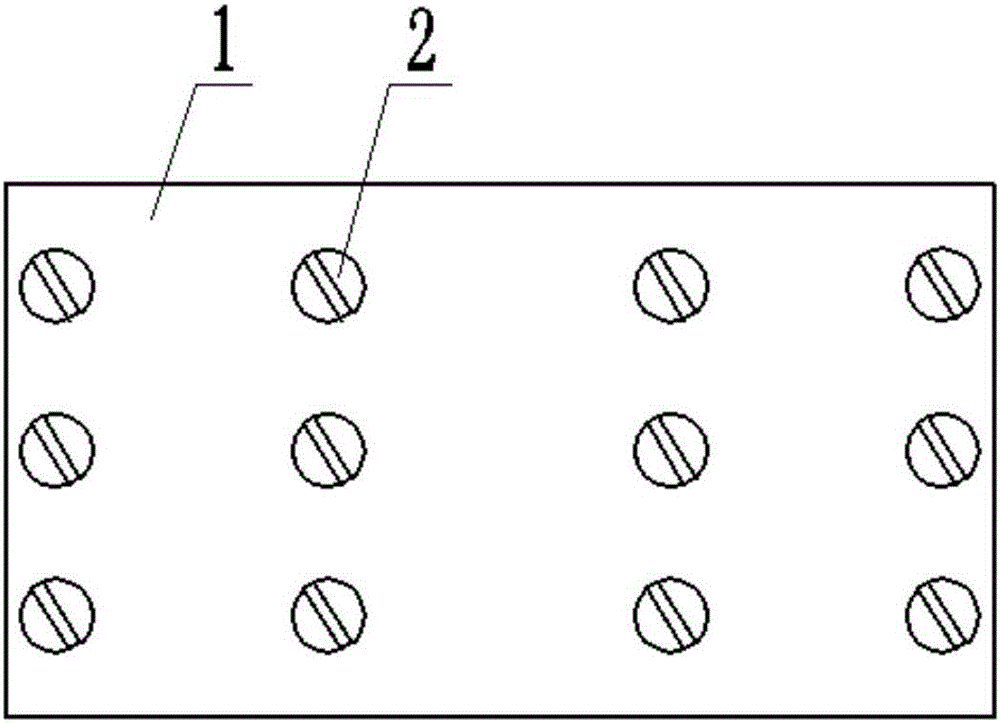

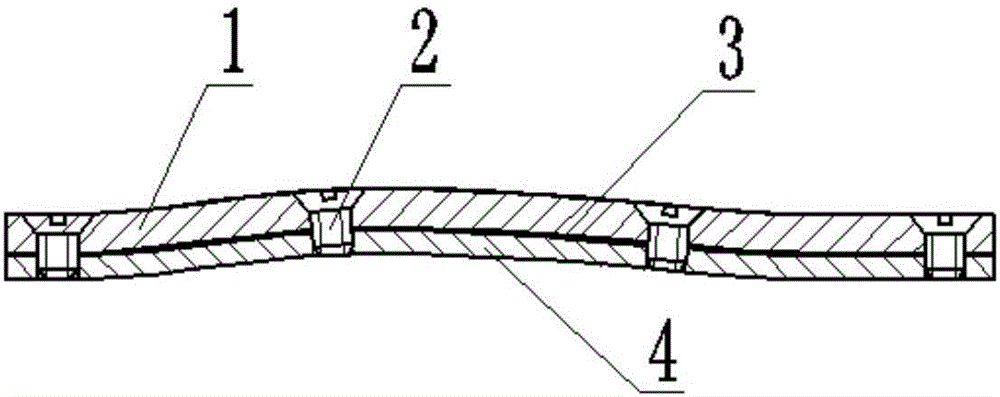

[0042] Use wire cutting to cut the shape memory alloy plate and spring steel plate into the following dimensions: shape memory alloy plate size (length × width × thickness) 76mm × 41mm × 3mm; spring steel plate size (length × width × thickness) 76mm × 41mm × 2mm; The required heating film size (length×width×thickness) is 76mm×41mm×(0.1~0.2)mm; a countersunk screw hole with a diameter of 3mm is made on the shape memory alloy plate;

[0043] Design and manufacture forming molds according to needs, including upper and lower forming molds. Place the shape memory alloy plate between the upper and lower forming molds, and tighten them with bolts and nuts. Place the mold with the shape memory alloy plate in the heating furnace, heat up to 800°C, keep it warm for 1 hour, and close The power supply of the heating furnace is cooled to room temperature with the furnace; the mold is disassembled, the shape memory alloy plate after forming is taken out, and annealed at 450 ℃ for 20 minutes; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com