Anodic oxidation process for automobile aluminum alloy baggage holders

A car luggage rack and anodic oxidation technology, which is applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of failing to pass the test of alkali resistance, etc., and achieve the effect of strengthening functionality and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, a special production process sequence is adopted, and the main points are chemical polishing and hole sealing processes.

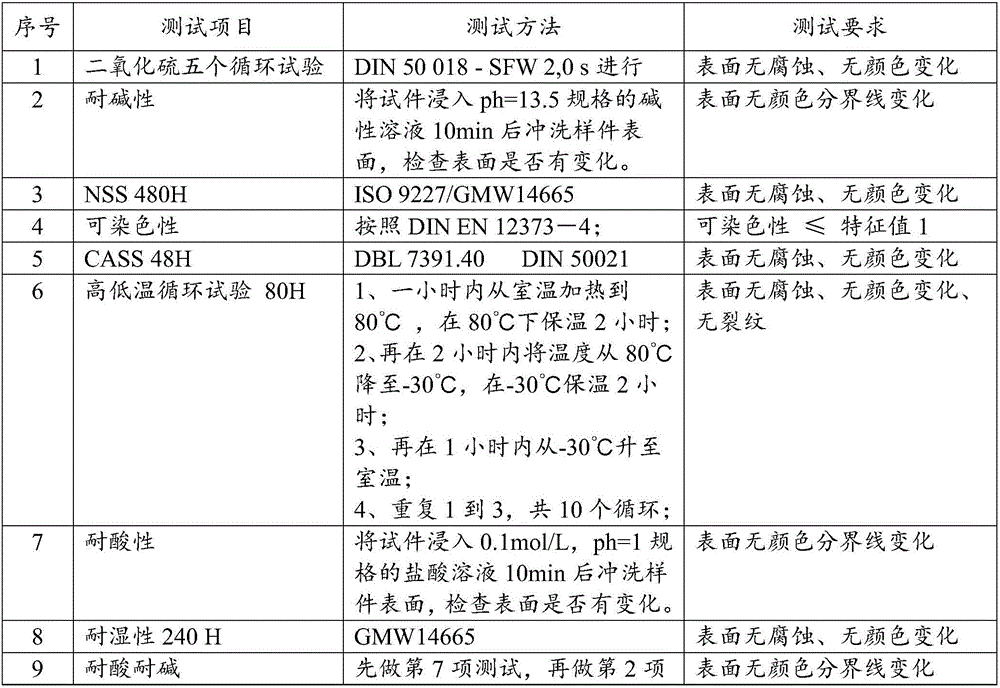

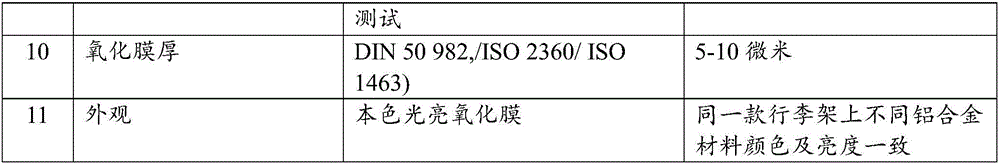

[0022] Specifically, two acid polishing, anodic oxidation and three-time sealing processes are adopted. The anodized film after this process has excellent corrosion resistance and high and low temperature resistance, and is required to meet the requirements in Table 1.

[0023] Table 1 shows the test requirements for the anodized film.

[0024]

[0025]

[0026] For realizing table 1 requirement, the present invention is realized like this. Its process steps include:

[0027] (1) Feeding; (2) Wax removal; (3) Double washing; (4) Chemical polishing; (5) Triple washing; (6) Lighting; (7) Triple washing; (8) Anodizing; (9) (10) low temperature sealing; (11) triple washing; (12) room temperature sealing; (13) triple washing; (14) high temperature sealing; (15) triple washing; (16) drying; (17) Cutting inspection.

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com