Rapid dyeing method of liquid dye for suede ultrafine fiber synthetic leather

A technology of superfine fiber and liquid dyes, applied in the field of dyeing, can solve the problems of low dye absorption rate, poor dyeing fastness, and long dyeing time, and achieve high dye absorption rate, simple dyeing method, and less discharge of dyeing wastewater Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

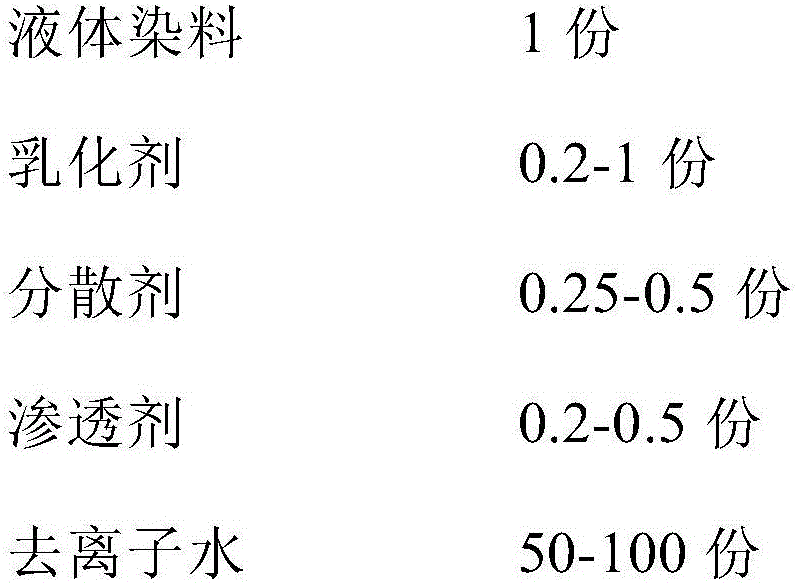

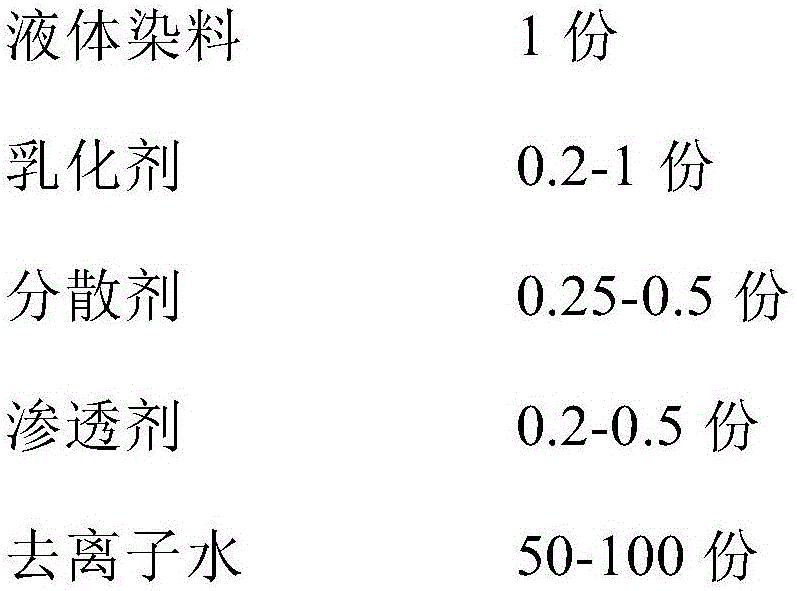

[0022] In parts by weight, pour 1 part of liquid dye Ruby PB into a dry emulsifier, add 0.2 part of sulfated castor oil, 0.5 part of dispersant MF and stir evenly; then add 0.5 part of penetrant JRC and continue stirring ; Finally, add 50 parts of deionized water, stir until the emulsification is uniform, and obtain the dye water treatment solution. Put the filtered dye water treatment solution into a continuous padding tank, and control the base cloth with a liquid rate of 55% through one dipping and one rolling; dry at 130°C for 10 minutes, then cool and roll , You can get dyed superfine fiber synthetic leather.

Embodiment 2

[0024] In parts by weight, pour 1 part of liquid dye Sapphire Blue PR into a dry emulsifier, add 0.4 parts of Pingpingjia O-25, 0.25 parts of dispersant NNO and stir evenly; then add 0.3 parts of penetrant T and continue stirring ; Finally, add 80 parts of deionized water, stir until the emulsification is uniform, and obtain the dye water treatment solution. Put the filtered dye water treatment solution into a continuous padding tank, and control the liquid rate of the base fabric to 60% through one dipping and one rolling; dry it at 120°C for 15 minutes, then cool it and wind it up , You can get dyed superfine fiber synthetic leather.

Embodiment 3

[0026] In parts by weight, pour 1 part of liquid dye black PR into a dry emulsifier, add 1 part of sulfated castor oil, 0.25 part of dispersant CS, and stir well; then add 0.2 part of penetrant JRC, and continue stirring; Finally, add 100 parts of deionized water, stir until the emulsification is uniform, and obtain the dye water treatment solution. Put the filtered dye water treatment solution into a continuous padding tank, and control the base cloth with a liquid rate of 65% through one dipping and one rolling; dry at 110°C for 12 minutes, then cool and wind , You can get dyed superfine fiber synthetic leather.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com