Center furnace liner L-shaped guide pipe vertical gas boiler

A gas-fired boiler and vertical boiler technology, applied in the direction of fixed conduit components, fluid heaters, heat exchangers, etc., can solve the problems of low fluid convective heat transfer coefficient, short flue gas flow, low water circulation rate, etc., to achieve enhanced The effect of natural convection heat transfer, increasing the radiation heat transfer area, and expanding the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

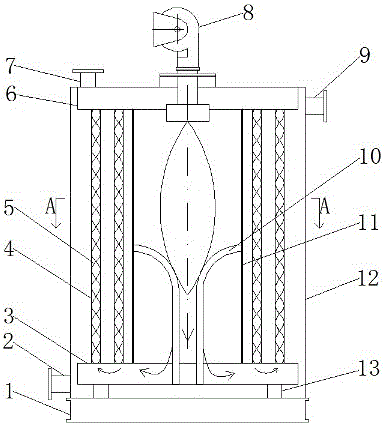

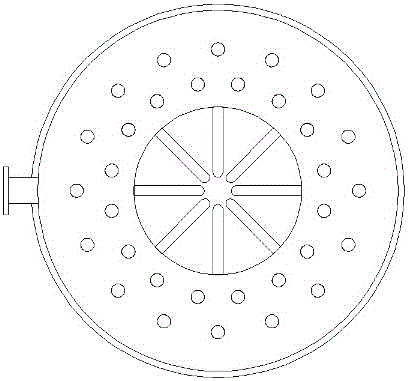

[0014] The cylinder of the central furnace L-shaped duct vertical gas boiler is equipped with a smoke collection box, a smoke transfer chamber, a furnace and a smoke pipe. The furnace is equipped with an L-shaped duct that is radial in the center. When installing, first put the furnace It is welded vertically with the upper smoke collecting box and the lower smoke transfer chamber, and then the L-shaped pipe is put in from the upper part of the furnace, and its upper end is welded with the hole in the middle wall of the furnace, and the lower end is welded with the bottom plate of the smoke transfer chamber; the smoke pipe The two ends are respectively welded on the annular tube plate of the smoke collection box and the smoke transfer chamber, and the steel sheet is twisted to make a spiral deflector, and placed in the smoke tube; the burner is fixed on the top of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com