Multi-channel parallel heat pipe radiator

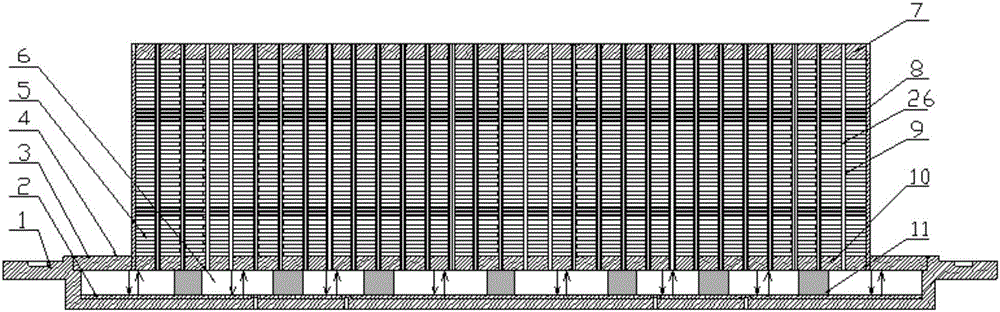

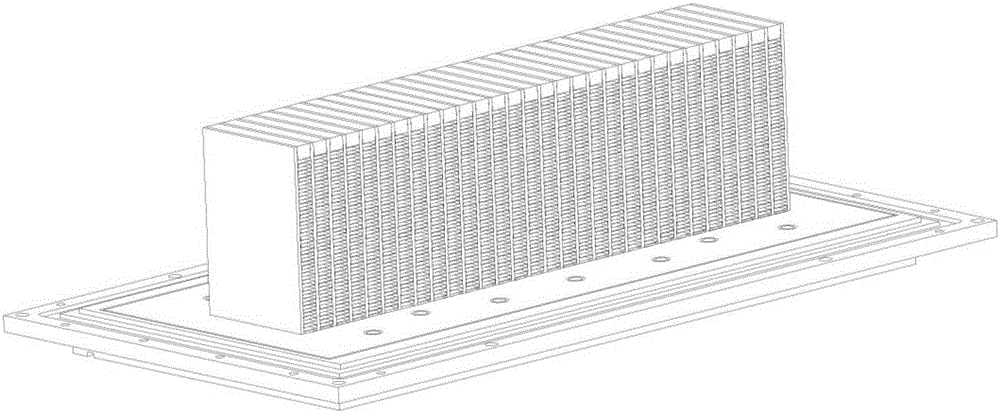

A heat pipe radiator, parallel technology, which is applied in the field of multi-channel parallel heat pipe radiator, can solve the problems of large flow resistance on both sides of the medium, fluid velocity not reaching turbulent flow, unsuitable phase change radiator, etc., to achieve working medium Fast reflow, high cooling power, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] like Image 6 As shown, an auxiliary metal fiber layer is provided on the side wall of the support structure 11 in this embodiment, and the capillary channel of the metal fiber layer at the top and bottom of the evaporation chamber 6 is connected through the auxiliary metal fiber layer, that is, on the outside of the support structure 11 The capillary fiber ring 21 is assembled, and the capillary fiber ring 21 is formed by stamping or moulding. The specific manufacturing process of this embodiment is:

[0048] (1) According to the design requirements, the extrusion process is used to complete the forming of the multi-channel parallel heat pipe 9 of the aluminum flat belt type. The shape of the phase change channel 26 is rectangular, the size is 2mm*2mm, the wall thickness is 0.5mm, and the secondary structure is U The shape of the groove 15, the width and height dimensions are 0.2mm*0.2mm, and the circle diameter is 0.2mm, and the inner cavity of the phase change chann...

Embodiment 2

[0056] like Figure 7 , Figure 8a , Figure 8b and Figure 8c As shown, the end of the tube body of the multi-channel parallel heat pipe 9 described in this embodiment connected to the substrate is provided with a sawtooth structure. Fibrous layer contact. Capillary contact realizes rapid return of working fluid. Method 4 is mechanically contacting fibers with liquid absorption in flat belt heat pipe flanging and bending grooves. Cut out the zigzag structure 23 after the edge of the flat heat pipe is divided, and bend it so that the heat pipe micro-grooves directly contact the lower fiber layer 2 for reflow. Its specific manufacturing process is:

[0057] (1) According to the design requirements, the extrusion process is used to complete the forming of the multi-channel parallel heat pipe 9 of the aluminum flat belt. The shape of the channel is rectangular, the size is 2mm*2mm, the wall thickness is 0.5mm, and the secondary structure is an Ω-shaped groove. Groove 16 has...

Embodiment 3

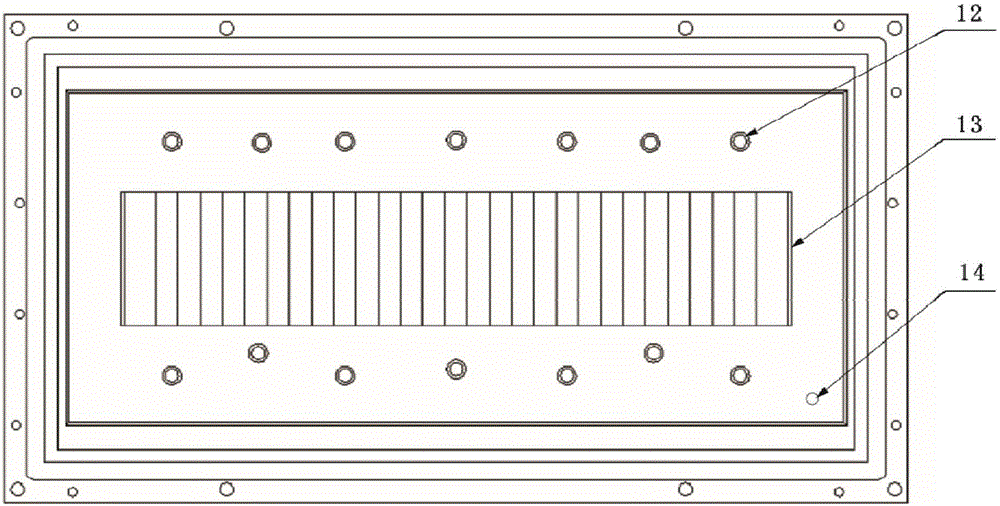

[0065] like Figure 9 As shown, auxiliary grooves are provided on the side wall of the supporting structure 11 in this embodiment, and the method 4 of fast return flow of the working fluid by capillary contact is to assemble the auxiliary groove ring outside the supporting structure 11 . Machining or laser processing on the upper base plate 3 produces 6 micro-grooves in the evaporation cavity, and then simultaneously sinters the upper fiber layer 22 and the lower fiber layer 2 in the cavity surfaces of the upper base plate 3 and the lower base plate 1, and assembles auxiliary grooves outside the supporting structure 11 The ring 24 is reflowed. Its specific manufacturing process is:

[0066] (1) According to the design requirements, the extrusion process is used to complete the forming of the multi-channel parallel heat pipe 9 of the aluminum flat belt. The shape of the channel is rectangular, the size is 3mm*2mm, the wall thickness is 0.5mm, and the secondary structure is a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com