Automatic inspection machine of step electrode

An automatic inspection and step electrode technology, applied in the field of optical inspection, can solve the problems of easy eye fatigue, easy misjudgment or missed judgment, and decreased efficiency, so as to avoid misjudgment of defects, ensure accuracy, and reduce labor costs.

Active Publication Date: 2017-05-10

厦门福信光电集成有限公司

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the line detection of LCD screens adopts manual visual inspection. The inspectors work for a long time and their eyes are prone to fatigue, resulting in a decrease in efficiency and prone to misjudgments or missed judgments.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

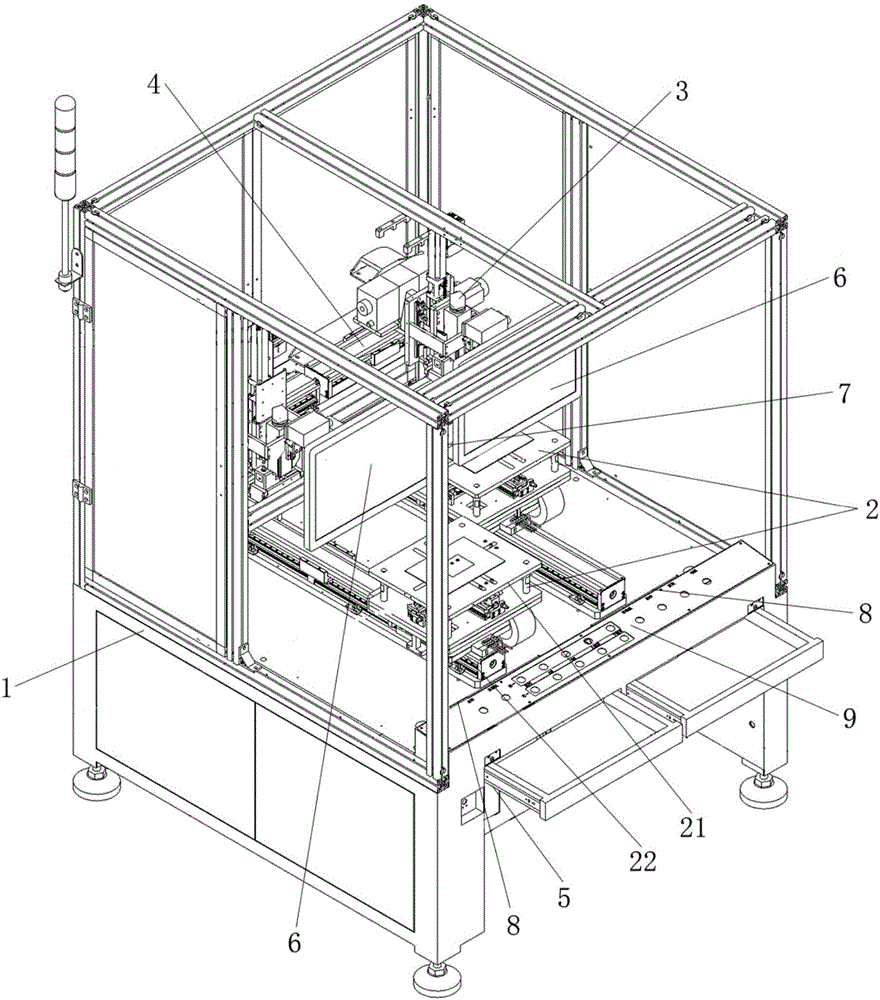

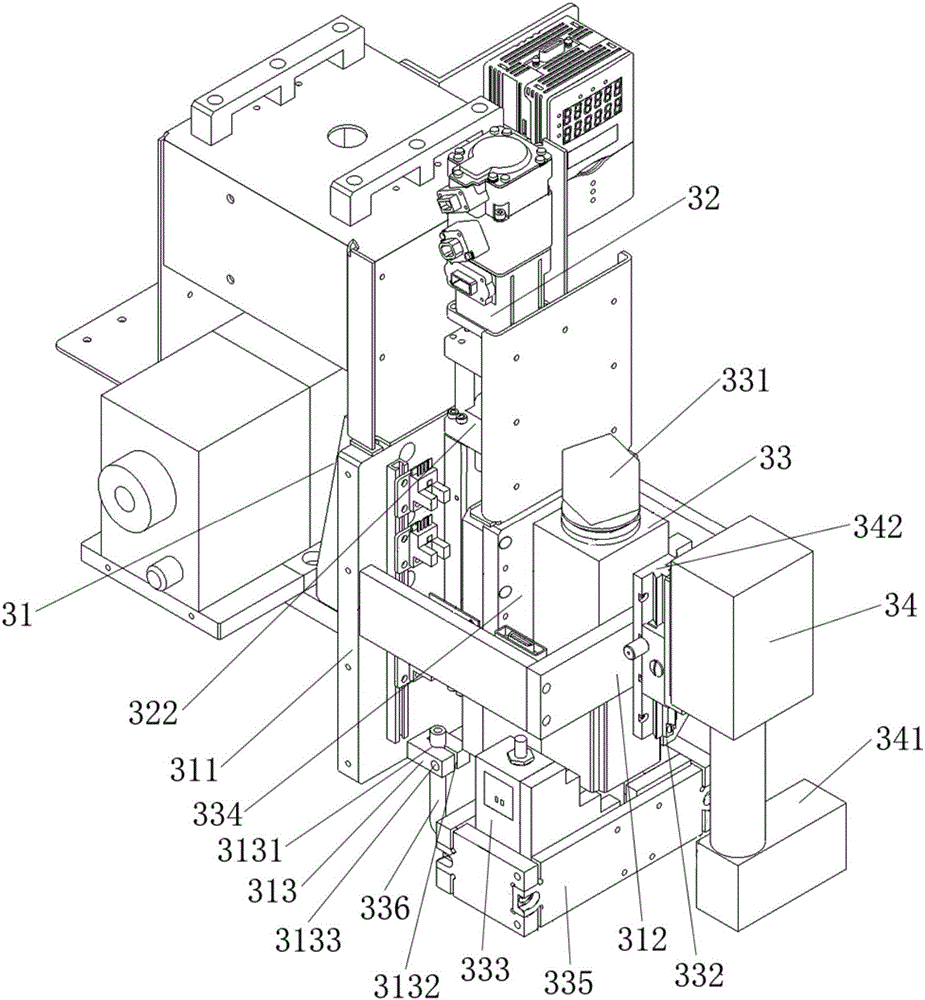

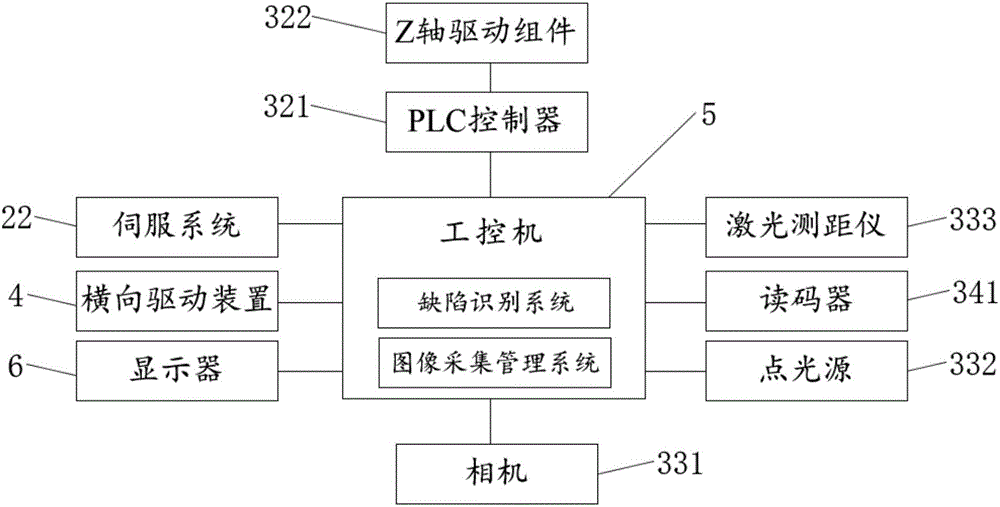

[0031] Cooperate figure 1 , figure 2 and image 3 As shown, the present invention discloses a stepped electrode automatic inspection machine, comprising a frame 1, on which a detection platform 2, an image acquisition device 3, a lateral drive device 4, an industrial computer 5 and a display 6 are arranged, wherein:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an automatic inspection machine of a step electrode. The automatic inspection machine comprises a rack, an image collection device, a transverse drive device, an industrial personal computer and a display screen, wherein the rack is provided with a detection platform and comprises a microscope stage and a servo system; the image collection device is located at the upper part of the microscope stage and comprises a base frame, a Z-axis adjusting mechanism, a shooting mechanism and a code reading mechanism; the Z-axis adjusting mechanism, the shooting mechanism and the code reading mechanism are arranged on the base frame; the Z-axis adjusting mechanism comprises a PLC and a Z-axis drive assembly; the Z-axis drive assembly is controlled by the PLC and drives the shooting mechanism to move; the shooting mechanism comprises a camera, a point light source and a laser range finder; the laser range finder is used for measuring the distance between the laser range finder and the surface of a liquid crystal screen; the code reading mechanism is used for reading bar code information carried on the liquid crystal screen; the transverse drive device is used for determining transverse motion of the image collection device relative to the detection platform; the industrial personal computer is connected with the servo system, the PLC, the camera, the point light source and the laser range finder separately and is provided with an image collection management system and a defect identification system; and the display screen is used for displaying an operation interface and a defect detection result.

Description

technical field [0001] The invention relates to the technical field of optical inspection, in particular to an automatic inspection machine for stepped electrodes. Background technique [0002] Liquid crystal displays have the advantages of small size, low power consumption, and low radiation, and have been widely used in electronic equipment such as desktop computers, notebook computers, mobile phones, LCD TVs, and car computers. The liquid crystal display screen is manufactured through a complex production process, and the signal lines on it are prone to various defects. Therefore, it is necessary to detect the circuit defects on the liquid crystal display screen to prevent defective products from flowing out. [0003] At present, the line detection of LCD screens adopts manual visual inspection. The inspectors work for a long time and their eyes are prone to fatigue, resulting in a decrease in efficiency and prone to misjudgments or missed judgments. Contents of the inv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/88

CPCG01N21/8851

Inventor 陈思华黄海明陈松岩翁德胜王士奇王晓丹

Owner 厦门福信光电集成有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com