Novel silver-introduced hafnium-nitride-membrane high-infrared-reflection durable material

A hafnium nitride film and infrared reflection technology, which is applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problem of low melting point, easy corrosion, no high durability and high infrared reflection, poor durability to achieve excellent durability and good infrared reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

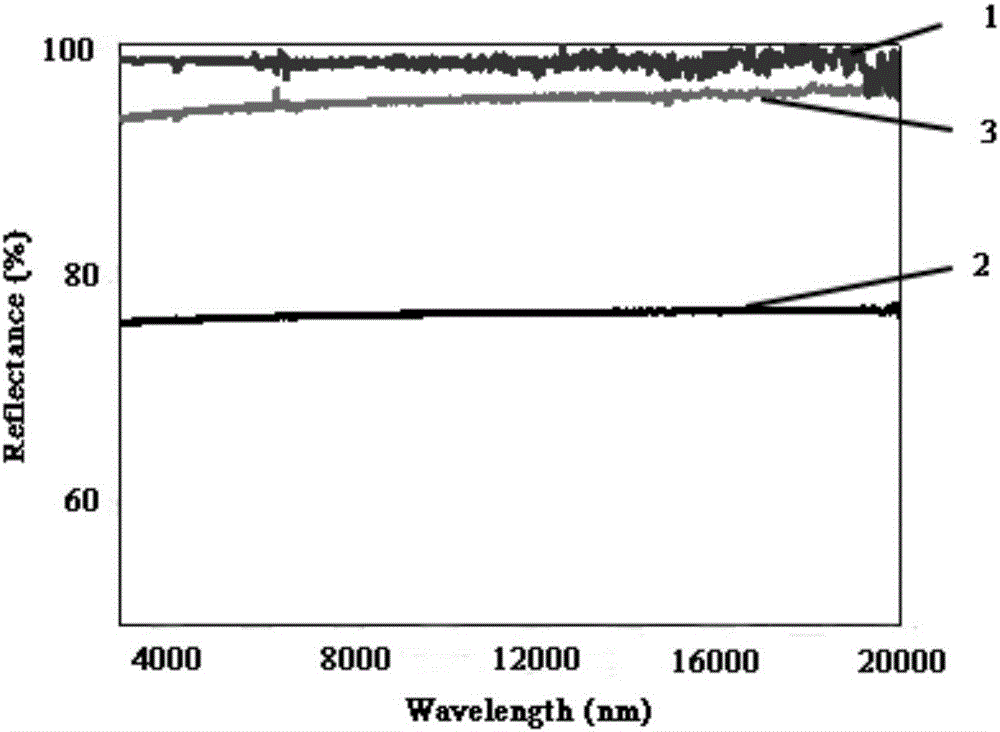

[0024] A new type of silver-introduced hafnium nitride film high infrared reflective durable material, the material is HfN-Ag composed of HfN and Ag x The film, wherein the content of Ag is 3.5 at.%.

[0025] The preparation method of the novel silver-introduced hafnium nitride film high-infrared reflective durable material of this embodiment is as follows: (1) select a silicon wafer as a substrate, and ultrasonically clean it in acetone, ethanol, and deionized water for 20 minutes each; (2) Put the pure Hf target and Ag target into the magnetron sputtering chamber, adjust the base distance of the target to 70mm, and evacuate to 4×10 -4 Pa, the substrate is heated up to 200°C, the pure Hf target adopts a DC power supply, and the sputtering power is set to 150W, and the pure Ag target adopts an RF power supply, and the sputtering power is set to 60W; (3) the N 2 gas and Ar gas, N 2 The gas flow rate is 2.8sccm, the Ar gas flow rate is 80sccm, the working pressure and bias vol...

Embodiment 2

[0027] A new type of silver-introduced hafnium nitride film high infrared reflective durable material, the material is HfN-Ag composed of HfN and Ag x film, wherein the content of Ag is 3.1 at.%.

[0028] The preparation method of the novel silver-introduced hafnium nitride film high-infrared reflective durable material in this embodiment is as follows: (1) select a glass substrate as the substrate, and ultrasonically clean it in acetone, ethanol, and deionized water for 20 minutes each; (2) Put the pure Hf target and Ag target into the magnetron sputtering chamber, adjust the base distance of the target to 70mm, and evacuate to 4×10 -4 Pa, the substrate is heated up to 200°C, the pure Hf target adopts a DC power supply, and the sputtering power is set to 150W, and the pure Ag target adopts an RF power supply, and the sputtering power is set to 50W; (3) N 2 gas and Ar gas, N 2 The gas flow rate is 2.8sccm, the Ar gas flow rate is 80sccm, the working pressure and bias voltage...

Embodiment 3

[0030] A new type of silver-introduced hafnium nitride film high infrared reflective durable material, the material is HfN-Ag composed of HfN and Ag x film, wherein the content of Ag is 0.8 at.%.

[0031] The preparation method of the novel silver-introduced hafnium nitride film high-infrared reflective durable material in this embodiment is as follows: (1) select a glass substrate as the substrate, and ultrasonically clean it in acetone, ethanol, and deionized water for 20 minutes each; (2) adjust The base distance of the target is 70mm, put the pure Hf target and the Ag target into the magnetron sputtering chamber, and evacuate to 4×10 -4 Pa, the substrate is heated up to 200°C, the pure Hf target adopts a DC power supply, and the sputtering power is set to 150W, and the pure Ag target adopts an RF power supply, and the sputtering power is set to 20W; (3) N 2 gas and Ar gas, N 2 The gas flow rate is 2.8sccm, the Ar gas flow rate is 80sccm, the working pressure and bias vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com