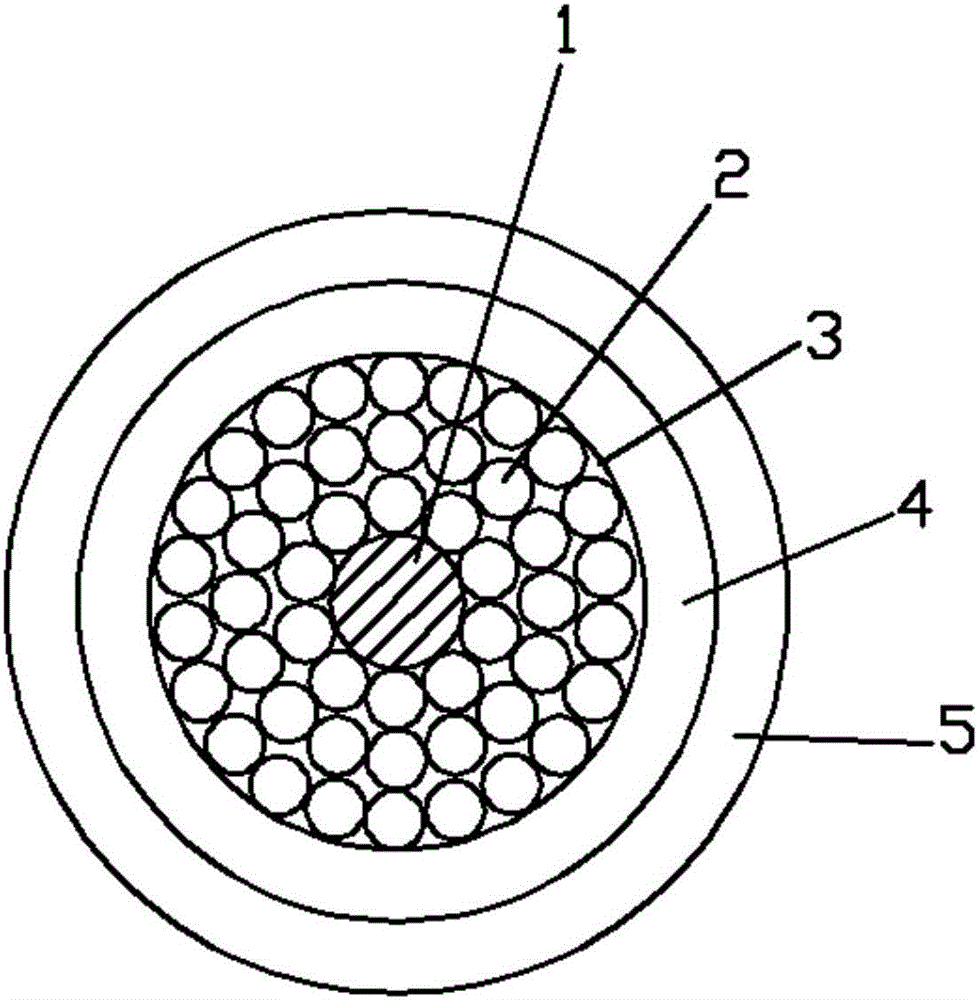

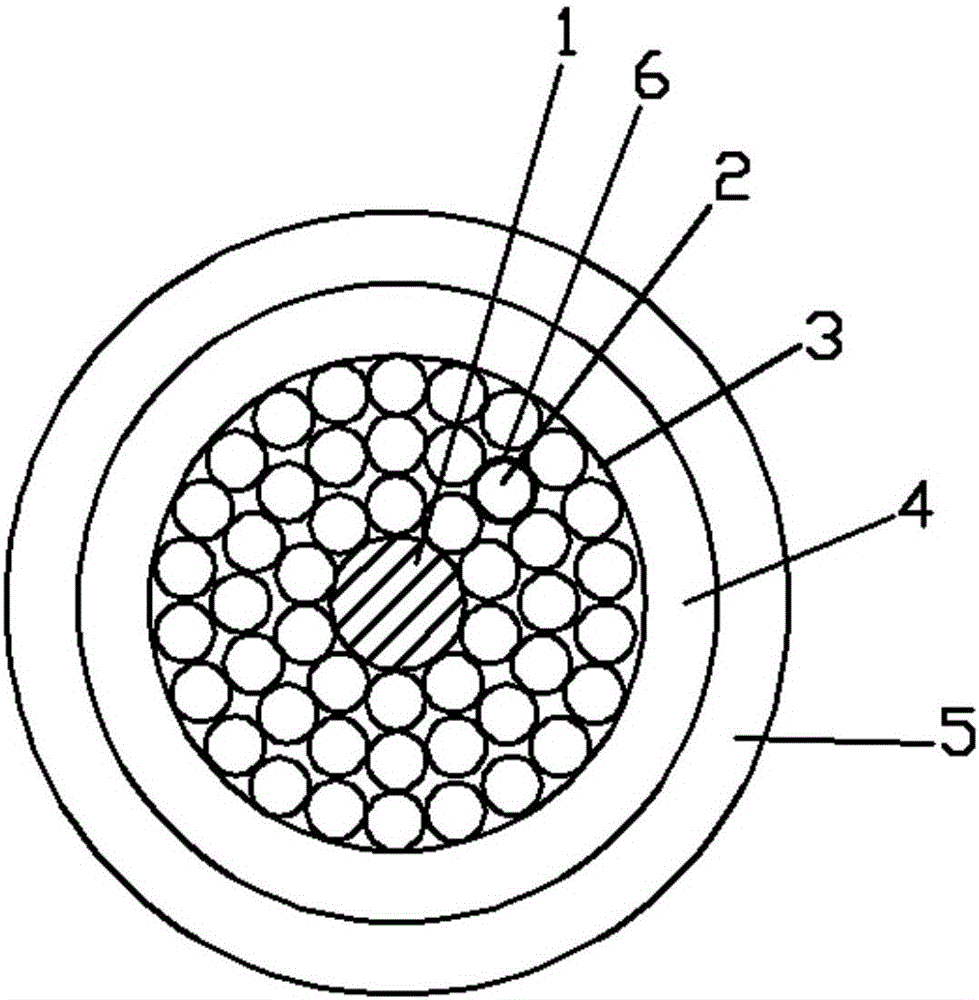

Continuous tube cable with steel wire for load bearing

A coiled tubing and steel wire technology, which is applied in the manufacture of cables, insulated cables, and cables/conductors, etc., can solve problems such as limited life of load-bearing structures, insulation damage, leakage accidents, etc., to enhance load-bearing performance, reduce requirements, and improve bearing capacity Effect of mechanical load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The chemical composition of coiled tubing is: C: 0.1%, Cr: 1.1%, Ni: 0.72%, Mo: 0.32%, V: 0.11%, Nb: 0.05%, B: 0.034%, P: 0.015%, S: 0.008%, the rest is Fe and unavoidable impurities.

Embodiment 2

[0024] The chemical composition of coiled tubing is: C: 0.11%, Cr: 1.1%, Ni: 0.7%, Mo: 0.3%, V: 0.1%, Nb: 0.06%, B: 0.032%, P: 0.015%, S: 0.009%, the rest is Fe and unavoidable impurities.

Embodiment 3

[0026] The chemical composition of coiled tubing is: C: 0.12%, Cr: 1%, Ni: 0.71%, Mo: 0.3%, V: 0.12%, Nb: 0.05%, B: 0.035%, P: 0.016%, S: 0.01%, the rest is Fe and unavoidable impurities.

[0027] Preferably, the preparation process of the steel strip used for manufacturing coiled tubing is as follows: first, the above-mentioned components are smelted according to the corresponding mass percentage and cast into a slab; second, the slab is heated to 1236°C, and the holding time is 2.0 min / mm, depending on the thickness of the slab; third, the temperature control range of the finish rolling is 792°C, and the temperature is kept for 15 minutes; fourth, quenching is carried out after heating to 1024°C; fifth, high temperature tempering is carried out at 664°C Processing; Sixth, natural cooling in the air. The steel strip after the above heat treatment not only has excellent welding performance, but also has excellent ductility and plasticity, which can greatly improve the service...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com