Insulated isolation cloth

An insulation isolation and insulation layer technology, applied in the field of power transmission and transformation operation and maintenance, can solve the problems of easy adhesion of dirt on the surface of the insulation blanket, lack of waterproof and moisture-proof functions, and reduced pin-type creepage distance, etc., to improve the fit and connection stability, improve waterproof and moisture-proof effect, and prevent accidental electric shock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

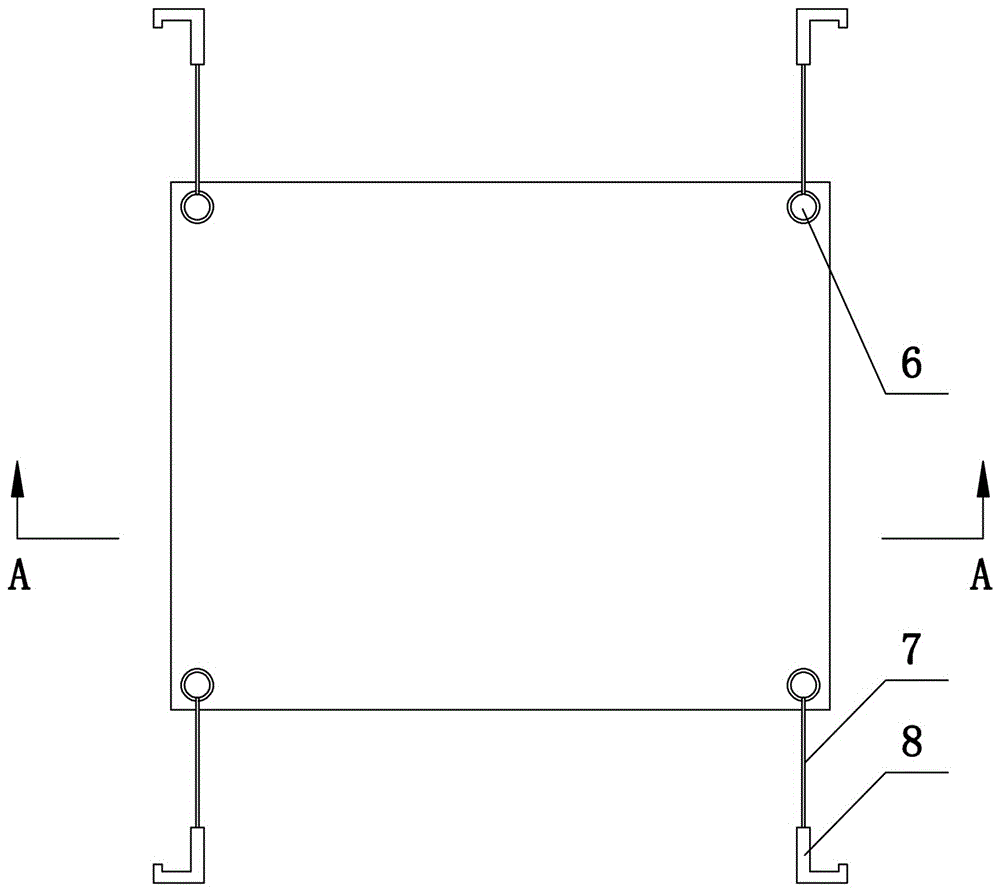

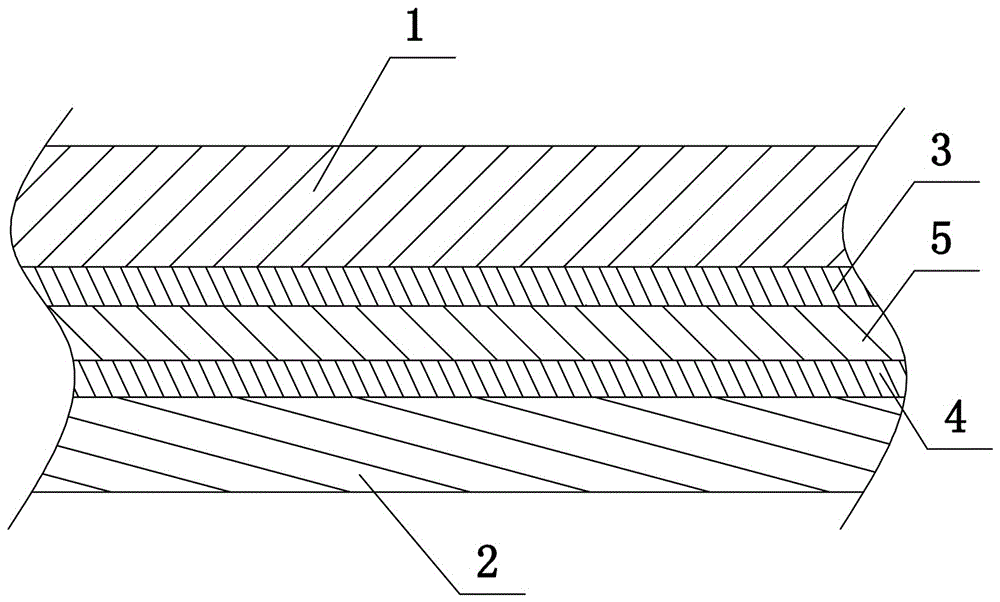

[0029] Such as figure 1 and figure 2 As shown, the present invention discloses an insulating and insulating cloth. The insulating and insulating cloth is rectangular as a whole, including a waterproof layer 1, a support layer and an inner lining layer 2 arranged from the outside to the inside. The waterproof layer 1 includes a spun-bonded non-woven fabric and a coated The waterproof coating on the outer surface of the spunbond non-woven fabric, the waterproof coating is a PTFE film, and the support layer includes an upper adhesive layer 3, a lower adhesive layer 4 and a layer between the upper adhesive layer 3 and the lower adhesive layer 4 Insulation layer 5, insulation layer 5 includes polyurethane, antioxidant and cross-linking agent, antioxidant is a kind of in antioxidant 1010, antioxidant DLTP and antioxidant 168, preferred antioxidant DLTP in this implementation, adhesive The composite layer 3 and the lower adhesive layer 4 are made of water glass, the inner lining la...

Embodiment 2

[0033]Such as Figure 3 to Figure 5 As shown, the present invention includes a waterproof layer 1, a support layer and an inner lining layer 2 arranged from outside to inside, and the waterproof layer 1 includes a spunbonded nonwoven fabric and a waterproof coating coating the outer surface of the spunbonded nonwoven fabric, and the waterproof coating The layer is a PTFE film, and the supporting layer includes an upper adhesive layer 3, a lower adhesive layer 4, and an insulating layer 5 arranged between the upper adhesive layer 3 and the lower adhesive layer 4, and the insulating layer 5 includes polyurethane, antioxidant and cross-linking layer. Joint agent, antioxidant is one of antioxidant 1010, antioxidant DLTP and antioxidant 168, preferred antioxidant DLTP in this implementation, upper adhesive layer 3 and lower adhesive layer 4 adopt water glass, inner The lining layer 2 is polyamide fiber interwoven with warp and weft, the inner side of the waterproof layer 1 is bonde...

Embodiment 3

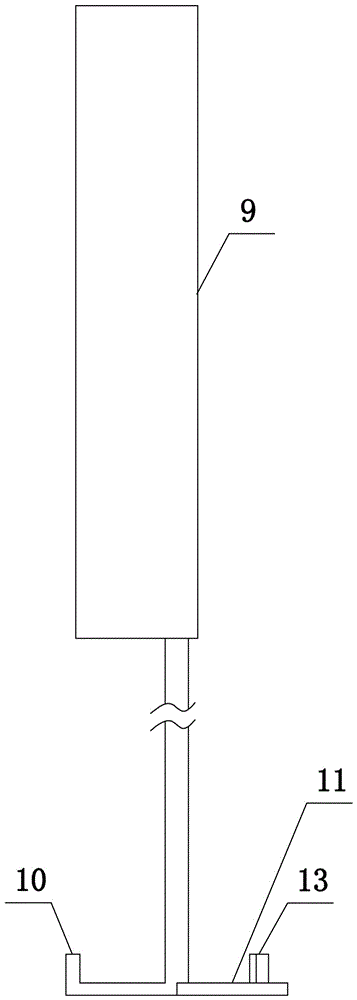

[0036] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is: as Figure 6 As shown, the ends of the first hook 10 and the L-shaped hook 13 are M-shaped, especially the ends of the first hook 10 and the L-shaped hook 13 are designed to be M-shaped, and the angle between the two free ends 14 of the M-shaped structure is 90°. °, the structure of the first hook 10 is shown in the figure. When this structure is in use, the two free ends of the M shape are attached to the two side walls of the lower end of the cuboid cabinet, and the corners of the cuboid are stuck in the concave of the M shape structure. At the groove 15, this design can effectively increase the contact area between the first hook 10 and the second hook and the electrical equipment, thereby improving the stable strength between the present invention and the electrical equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com