Seed chuck and ingot growing apparatus including same

A technology of growth device and crystal seed, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of deteriorating the quality of crystal ingots, etc., and achieves the advantages of improving thermal insulation performance, reducing heater power and improving reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the scope of the embodiments of the embodiments of the present invention can be determined from the matters disclosed in the embodiments, and the spirit of the present invention possessed by the embodiments includes actual modifications (such as addition, deletion, modification, etc.) Wait).

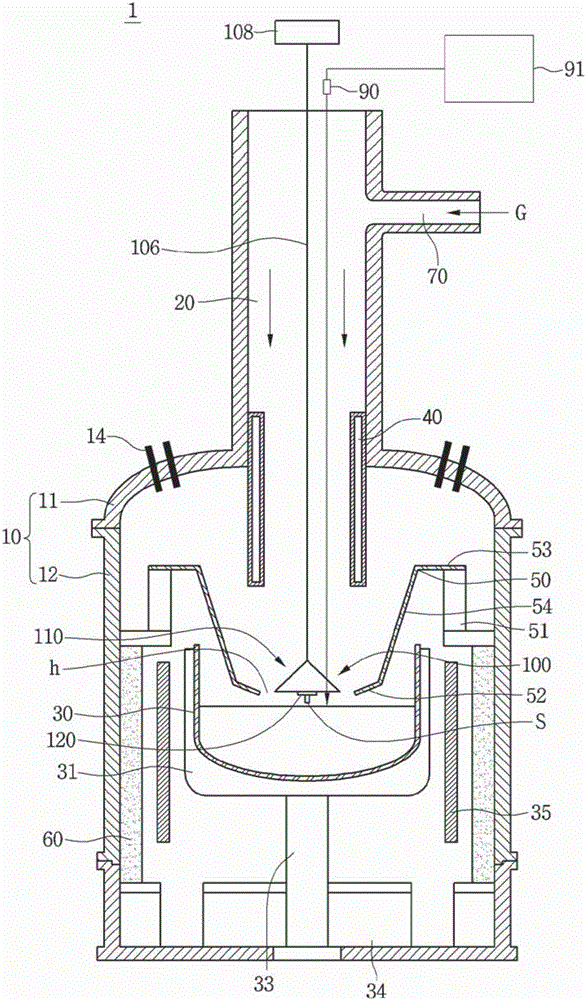

[0042] figure 1 is a view showing the ingot growing apparatus according to the embodiment.

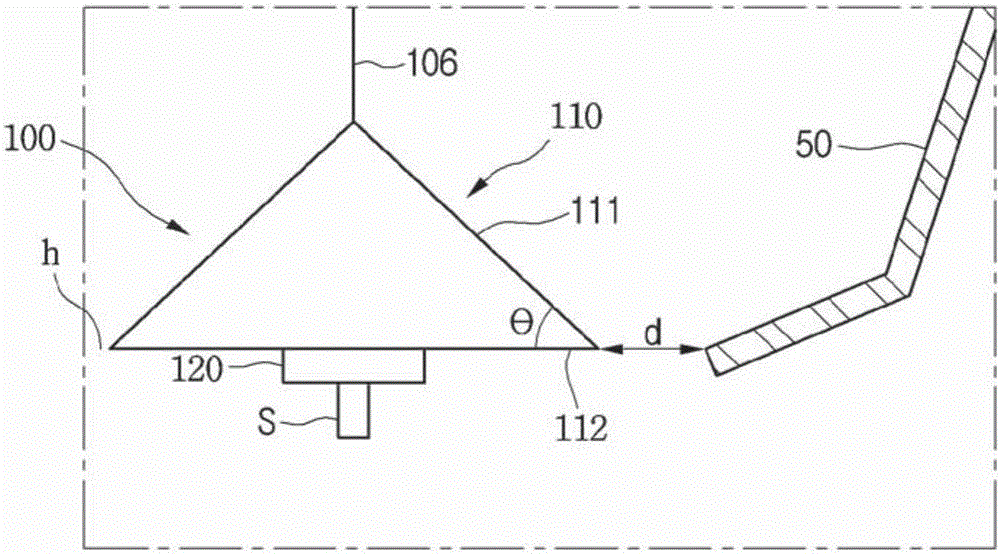

[0043] refer to figure 1 , the crystal ingot growth apparatus 1 may comprise a chamber 10, configured inside the chamber 10 and configured to accommodate hot zone structures 30 and 31 of silicon, configured to heat the heater 35 of the hot zone structures 30 and 31, located in the hot zone structure 30 Outer insulator 60 outside of and 31, upper insulator 50 positioned above hot zone structures 30 and 31 and having holes h through which ingots pass, and an ...

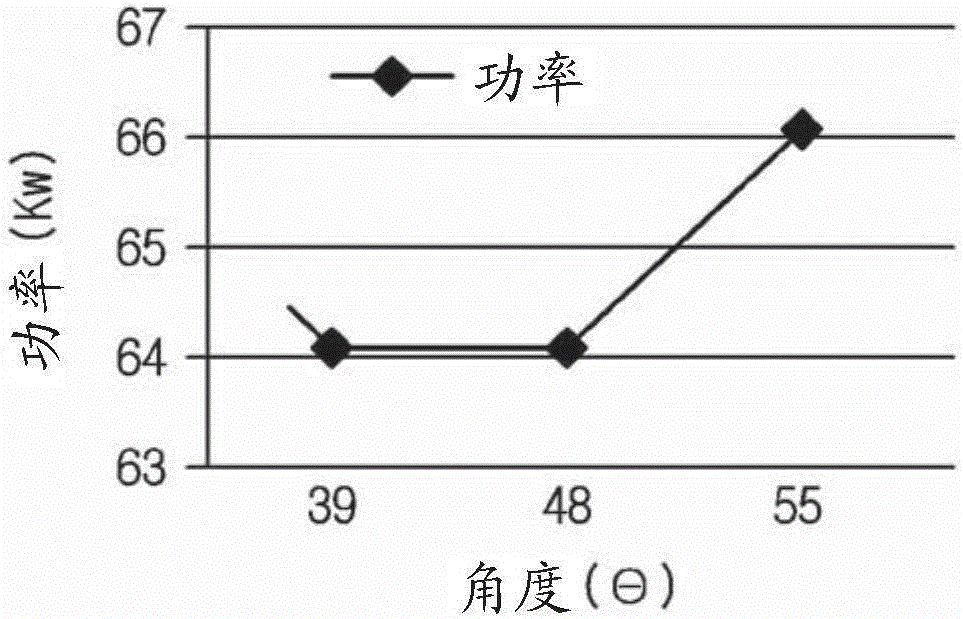

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com