Palbociclib pharmaceutical composition and preparation method thereof

A composition and drug technology, applied in the field of medicine, can solve the problems of low dissolution rate, the raw material cannot be fully absorbed, and the curative effect is reduced, and achieves the effects of good content uniformity, good dissolution effect, and improved curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The palbociclib pharmaceutical composition of the present embodiment is made up of the following components by mass percentage: palbociclib 27.78%, lactose 21.74%, microcrystalline cellulose 43.48%, carboxymethyl starch sodium 5% (granule Intragranular 3%, extragranular 2%), silicon dioxide 0.5%, magnesium stearate 1.5% (intragranular 1.0%, extragranular 0.5%).

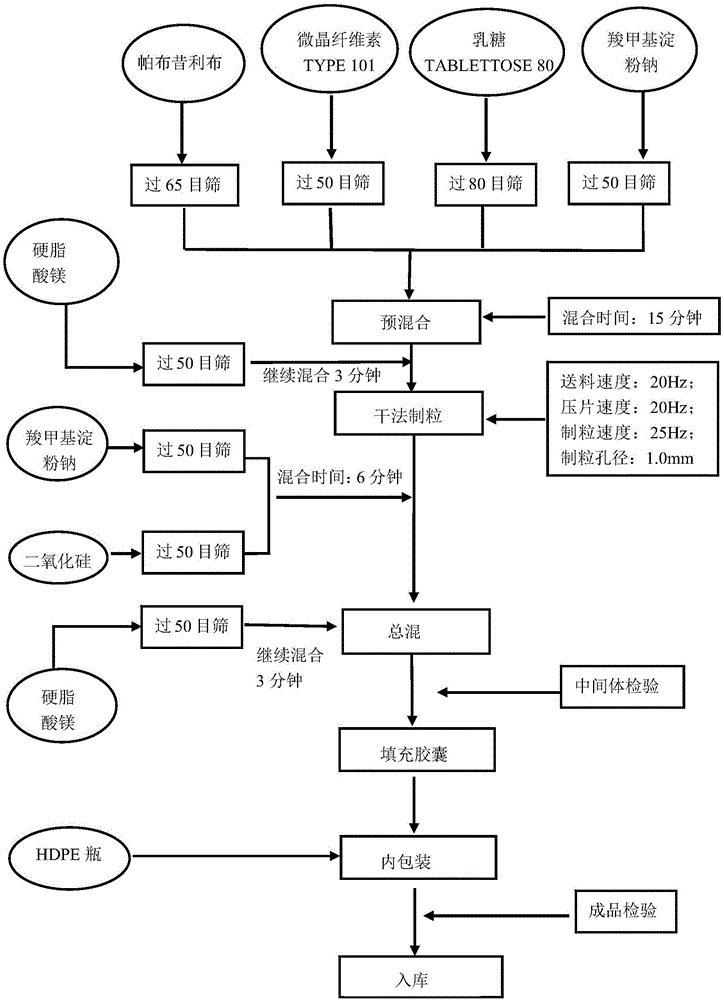

[0032] The above pharmaceutical composition is made into capsules, specification: 75 mg active ingredient / capsule; batch size: 10,000 capsules. The preparation method of the palbociclib pharmaceutical composition capsule of the present embodiment comprises the following steps (technical process such as figure 1 shown):

[0033] 1) Pass the palbociclib raw material through a 65-mesh sieve and set aside; pass lactose (TABLETTOSE 80) through a 80-mesh sieve and set aside; pass microcrystalline cellulose (TYPE 101), sodium carboxymethyl starch, stearin Magnesium acid and silicon dioxide are respectively passed th...

Embodiment 2

[0041] The palbociclib pharmaceutical composition of the present embodiment is made up of the following components by mass percentage: palbociclib 27.78%, lactose 21.74%, microcrystalline cellulose 43.48%, carboxymethyl starch sodium 5% (granule Intragranular 3%, extragranular 2%), silicon dioxide 0.5%, magnesium stearate 1.5% (intragranular 1.0%, extragranular 0.5%).

[0042] The above pharmaceutical composition is made into capsules, specification: 100 mg active ingredient / capsule; batch size: 10,000 capsules. The preparation method of the palbociclib pharmaceutical composition capsule of the present embodiment comprises the following steps:

[0043] 1) Pass the palbociclib raw material through a 65-mesh sieve and set aside; pass lactose (TABLETTOSE 80) through a 80-mesh sieve and set aside; pass microcrystalline cellulose (TYPE 101), sodium carboxymethyl starch, stearin Magnesium acid and silicon dioxide are respectively passed through a 50-mesh sieve for subsequent use; ...

Embodiment 3

[0051] The palbociclib pharmaceutical composition of the present embodiment is made up of the following components by mass percentage: palbociclib 27.78%, lactose 21.74%, microcrystalline cellulose 43.48%, carboxymethyl starch sodium 5% (granule Intragranular 3%, extragranular 2%), silicon dioxide 0.5%, magnesium stearate 1.5% (intragranular 1.0%, extragranular 0.5%).

[0052] The above pharmaceutical composition is made into capsules, specification: 125 mg active ingredient / capsule; batch size: 10,000 capsules. The preparation method of the palbociclib pharmaceutical composition capsule of the present embodiment comprises the following steps:

[0053] 1) Pass the palbociclib raw material through a 65-mesh sieve and set aside; pass lactose (TABLETTOSE 80) through a 80-mesh sieve and set aside; pass microcrystalline cellulose (TYPE 101), sodium carboxymethyl starch, stearin Magnesium acid and silicon dioxide are respectively passed through a 50-mesh sieve for subsequent use; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com