Hollow metal microneedle array, syringe needle, syringe and prefilled syringe

A microneedle array and syringe technology, applied in hypodermic injection devices, needles, microneedles, etc., can solve the problems of complex microneedle arrangement process, difficult to narrow the microneedle spacing, and small number of microneedles, and achieve a wide and consistent application range. The effect of good performance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

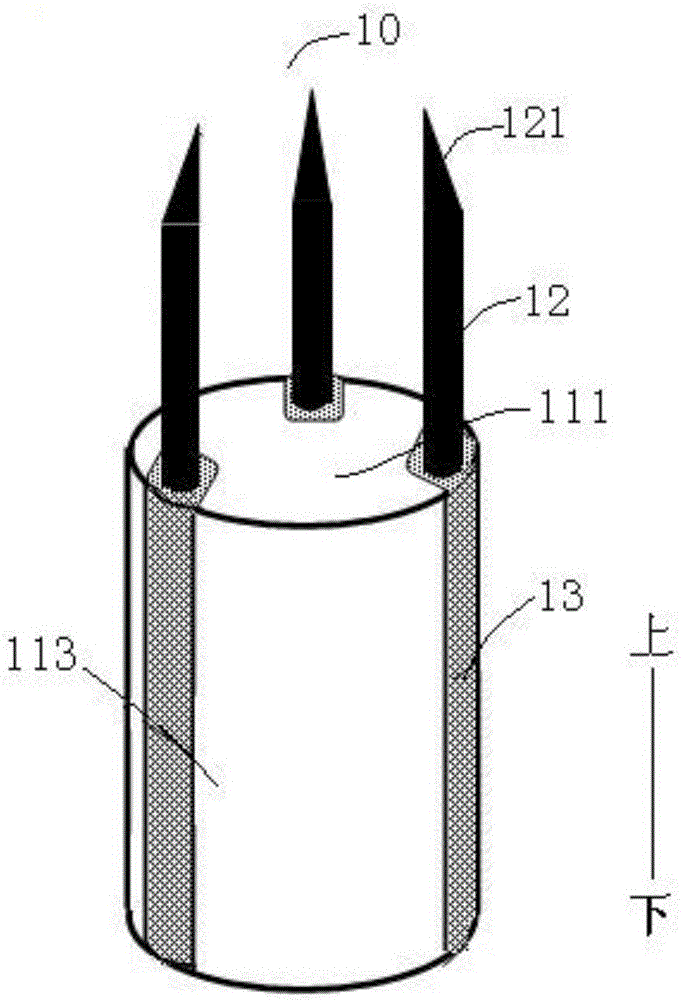

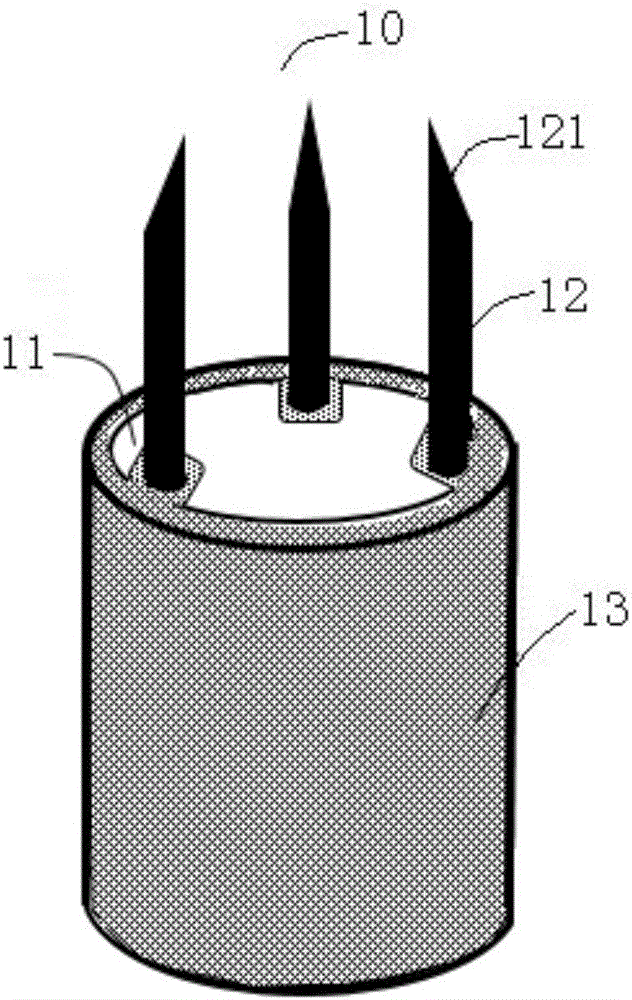

[0058] The following first combines the attached Figure 1 to Figure 10 The hollow metal microneedle array 10 according to the embodiment of the first aspect of the present invention will be described in detail.

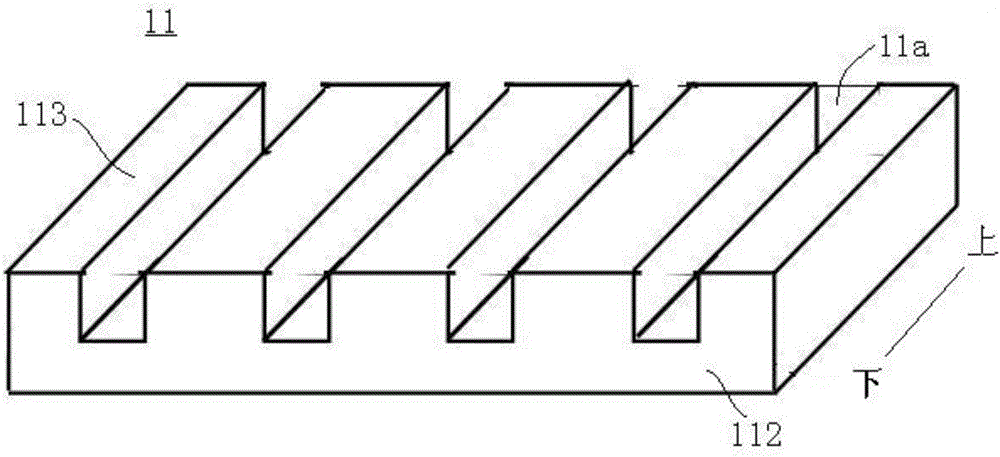

[0059] Such as Figure 1 to Figure 3 As shown, the hollow metal microneedle array 10 according to the embodiment of the present invention includes: a grooved base 11, a plurality of metal capillaries 12 and an adhesive 13, the grooved base 11 has an upper surface 111, a lower surface 112 and a side surface 113, with The side surface 113 of the groove base 11 is provided with at least two grooves 11a arranged at intervals, parallel to each other and pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com