Preparation of rapid forming die of individualized airway stent based on 3D printing

A technology of forming molds and 3D printing, applied in the directions of manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., which can solve the complex production process of commercial airway stents, prone to displacement of granulation tissue, and cannot reflect individuality. and other problems, to achieve the effect of overcoming the complex production process, reducing the risk of displacement, and producing fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with embodiment:

[0018] 1) Obtain CT scan data of the patient's chest and import it into medical image processing software to generate a three-dimensional numerical model of the airway wall;

[0019] 2) The three-dimensional numerical model of the patient's airway wall is used to intercept the airway of the diseased segment and smooth it;

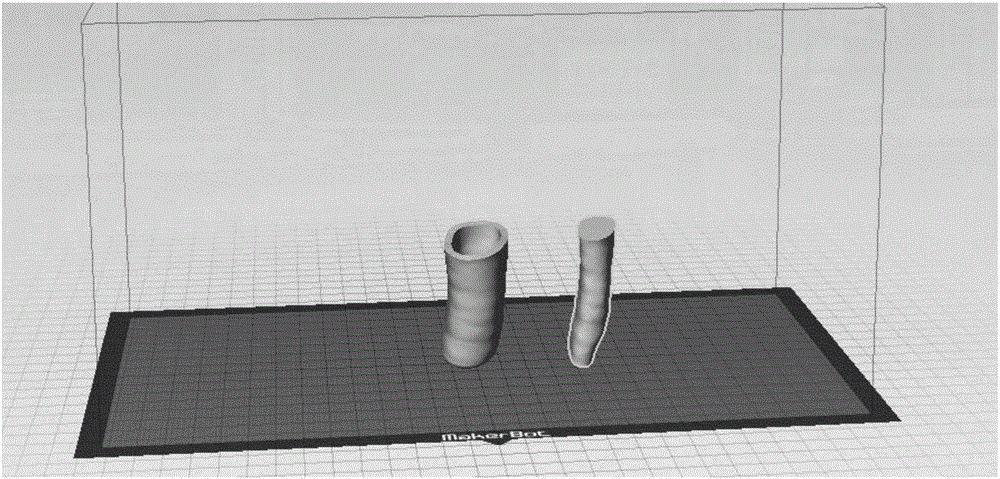

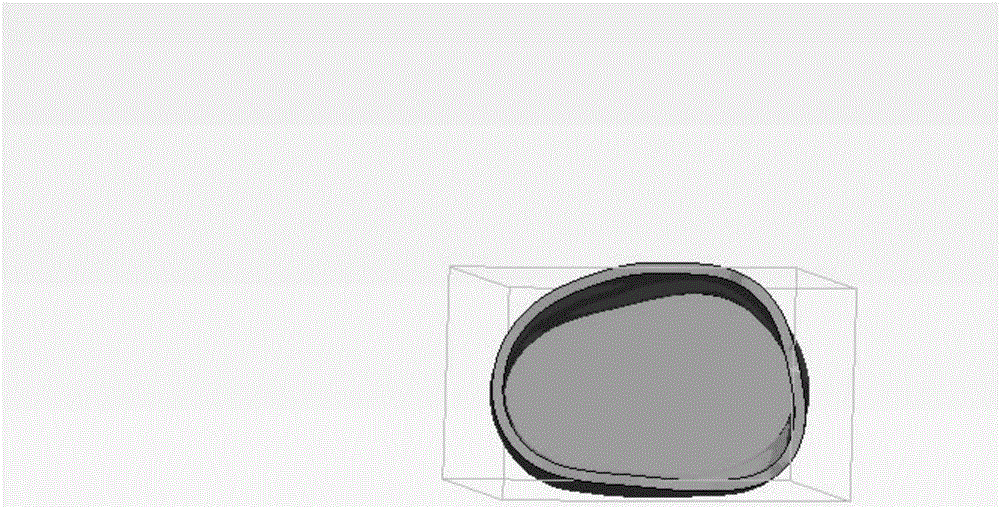

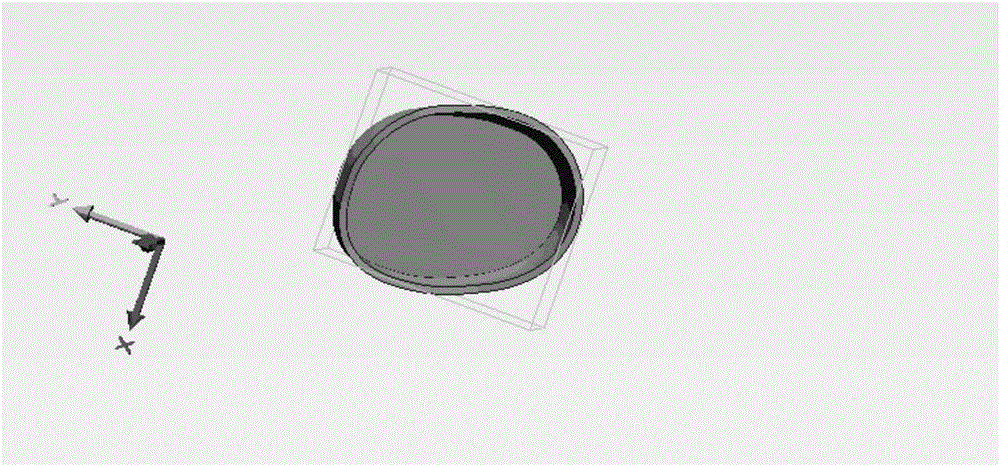

[0020] 3) Expand the smoothed airway wall by 10-30% to obtain the inner wall surface of the individualized airway stent, and then expand the inner wall surface by 1-4mm to obtain the outer wall surface of the individualized airway stent, and perform cavity on the inner wall surface Fill and generate a 3D solid mold core, expand the outer wall to a thickness of 1-3mm to generate a 3D solid to obtain the shell of the mold, intercept a small section of the outer wall of the mold shell and the lower two ports, and increase a certain thickness to obtain the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com