Cooling and conveying device

A cooling conveying and cooling mechanism technology, applied in cooling fluid circulation devices, household refrigeration devices, packaging, etc., can solve the problems of low utilization rate of cooling water, large water flow at one time, slow cooling speed, etc., and achieve better effect of cooling medicine , good cooling effect and accelerated cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

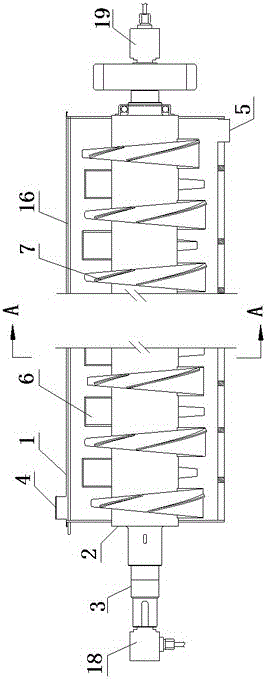

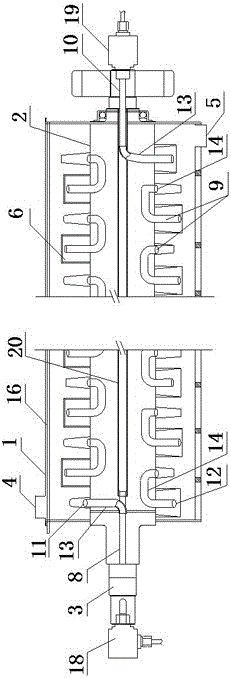

[0029] refer to Figure 1~Figure 2 , a cooling conveying device, comprising a material trough 1, a main shaft 2, a driving mechanism 3, a material inlet 4, a material outlet 5 and a cooling mechanism, the main shaft is intermittently provided with propulsion blades, and the propulsion blades include a cavity matrix 6 and the spiral blade 7 arranged on the base of the cavity, the cooling mechanism includes a water inlet pipe 8, a communication pipe 9 and a water outlet pipe 10 arranged in the main shaft, and the communication pipe connects the water inlet pipe, the air outlet pipe The cavity base and the water outlet pipe are connected in sequence.

[0030] The propulsion blades of the present invention are arranged intermittently, the base of the propulsion blades has a cavity matrix, and the inner space of the cavity matrix is connected by a communication pipe 9 . Both ends of the main shaft are made hollow to accommodate the water inlet pipe 8 and the water outlet pipe 10...

Embodiment 2

[0035] refer to Figure 1~2 , the present invention provides a preferred method of "the communication pipe connects the water inlet pipe, the cavity base body and the water outlet pipe in sequence": the cavity base body is provided with an interface so that the cavity base body communicates with the communication pipe . With such a structure, the water inlet pipe is connected to the communication pipe, the communication pipe is connected to the cavity base, and the communication pipe is connected to the water outlet pipe, so that the cooling water can flow freely from the water inlet pipe to the water outlet pipe.

[0036] Specifically, the two ends of the cavity base along the length direction are respectively provided with a water inlet port 11 and a water outlet port 12, and the communication pipe includes a communication pipe I13 and a communication pipe II14, and one end of the communication pipe I is connected to the water inlet pipe. Or the water outlet pipe is connect...

Embodiment 3

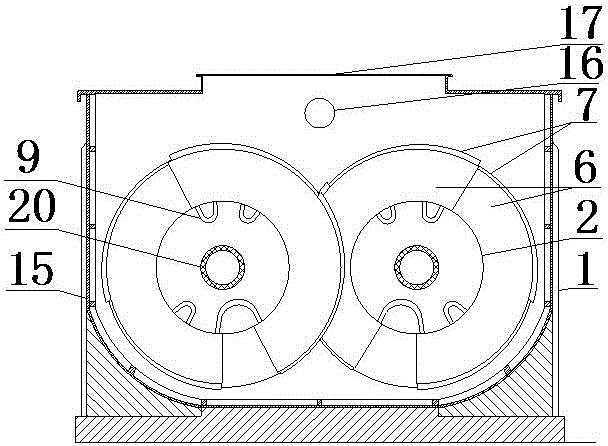

[0039] refer to image 3 , In the present invention, the shell of the trough is a double-layer structure, and a cavity is formed between the double-layer structures, and cooling water 15 is passed into the cavity.

[0040] The shell of the material trough is fed with cooling water and cooperates with the cooling mechanism to achieve more efficient cooling of the material. Specifically, interfaces can be provided at both ends of the trough to connect the cavity of the shell with the water inlet pipe and the water outlet pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com