Process for preparing methyl methacrylate according to aldol condensation method

A technology for the preparation of methyl methacrylate and aldol condensation, which is applied in the field of aldol condensation to prepare methyl methacrylate, can solve the problems of short catalyst life, loss, easy carbonization and deactivation, etc., and improve the single cycle Long service life, ensure online regeneration, and reduce the effect of carbon shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

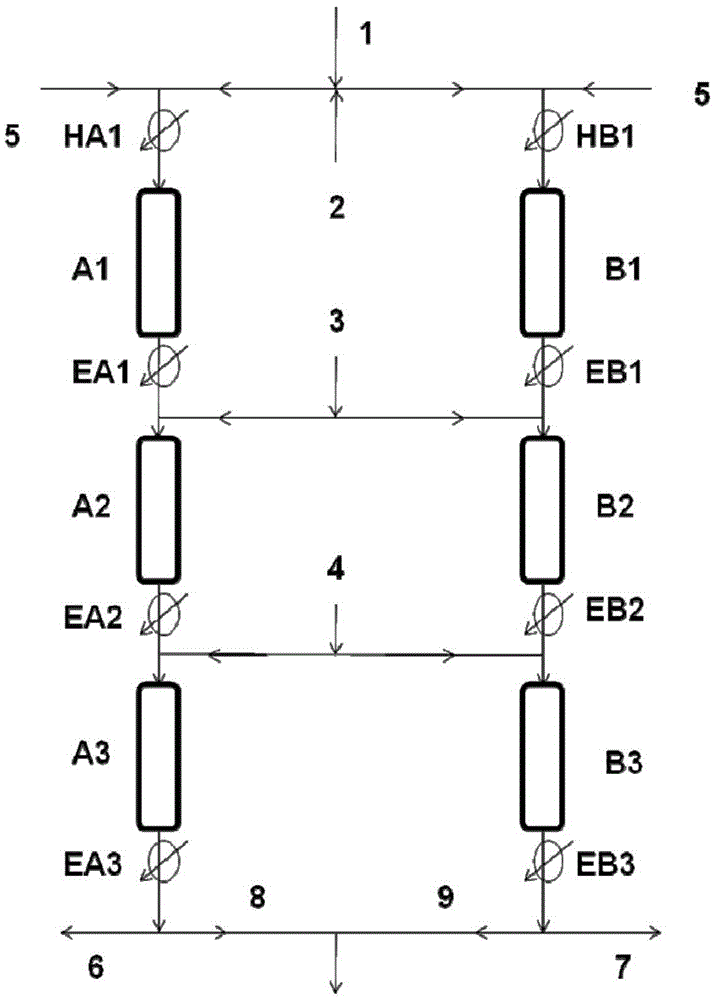

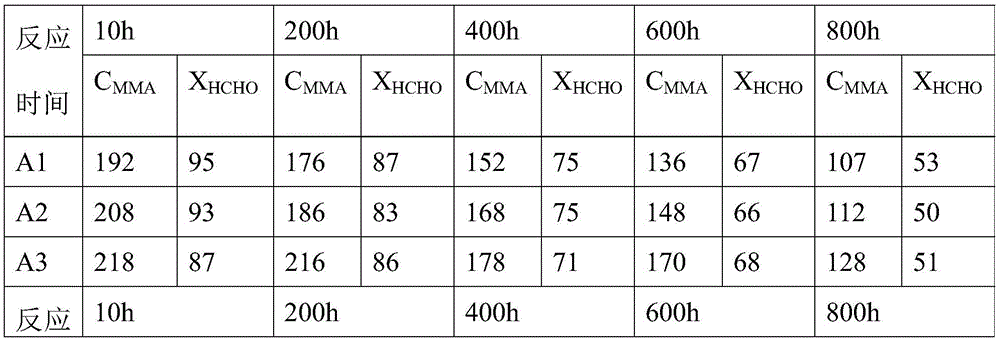

[0024] Such as figure 1 As shown, both the X series and the Y series have three reactors, that is, n=3, therefore, the formaldehyde source is equally divided into 3 feeds. In this embodiment, methyl propionate and formaldehyde are used as raw materials, which are realized by connecting multiple reactors in series and in parallel, specifically including the following steps:

[0025] The X series reactors are put into reaction, and the Y series reactors are waiting to be put into use.

[0026] Methyl propionate 1 and the first strand of formaldehyde 2 are heated together by the heat exchanger HA1 and enter the first reactor A1 of the X series. The reaction temperature is 330°C, the reaction pressure is 0.6MPa, and the molar ratio of methyl propionate to formaldehyde is 10:1, the liquid hourly space velocity is 1.8 / h; the material reacted in the first reactor A1 of the X series is cooled by the heat exchanger EA1, and enters the second reactor A2 of the X series together with th...

Embodiment 2

[0043] As a comparison, the single-cycle service life of the catalyst after formaldehyde is not fed in stages, that is, the case of n=1, was investigated. The effect is as follows.

[0044] Reactor operating conditions are shown in the table below.

[0045] temperature reflex reaction pressure liquid hourly space velocity Ester-aldehyde ratio A1 reactor 345℃ 0.6MPa 0.6 / h 3.33:1

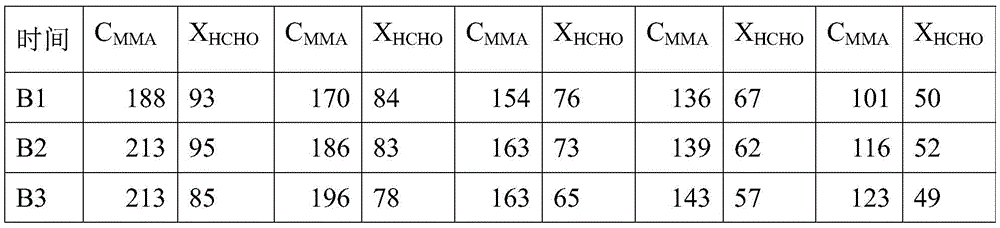

[0046] The results of the reactor reaction operation are shown in the table below.

[0047]

[0048] Note: Y MMA is the space-time yield of methyl methacrylate, g / (Kg.cat.h);

[0049] x HCHO is the effective conversion rate of formaldehyde, %.

[0050] The experimental results of embodiment 1 and embodiment 2 show, reduce catalyst load to original 1 / 3 (cluster 1.8 / h reduces to 0.6 / h), ester-aldehyde ratio reduces to 3.33:1 from 10:1, promptly guarantees that this reactor The unit processing capacity of the catalyst is consistent with the unit processing capacit...

Embodiment 3

[0052] Considering the case of n=5, the catalyst position is 20% Cs / SiO2.

[0053] The reaction operating conditions of each reactor of the X and Y series are shown in the table below.

[0054] A series temperature reflex reaction pressure liquid hourly space velocity Ester-aldehyde ratio A1 reactor 330℃ 0.6MPa 2.5 / h 15:1 A2 reactor 340℃ 0.5MPa 2.5 / h 14:1 A3 reactor 360℃ 0.4MPa 2.5 / h 13:1 A4 reactor 380℃ 0.3MPa 2.5 / h 12:1 A5 reactor 400℃ 0.2MPa 2.5 / h 11:1 B1 reactor 330℃ 0.6MPa 2.5 / h 15:1 B2 reactor 340℃ 0.5MPa 2.5 / h 14:1 B3 reactor 360℃ 0.4MPa 2.5 / h 13:1 B4 reactor 380℃ 0.3MPa 2.5 / h 12:1 B5 reactor 400℃ 0.2MPa 2.5 / h 11:1

[0055] Regeneration conditions are similar to Example 1.

[0056] According to above-mentioned conditions, the reaction result of each reactor is as follows:

[0057]

[0058]

[0059] Note: C MMA is the space-time yield of methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com