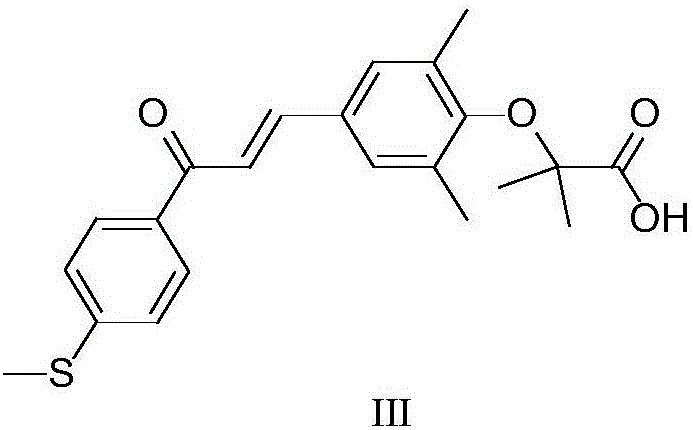

GFT505 and preparation method for intermediate thereof

An intermediate and time technology, applied in the field of preparation of GFT505 and its intermediates, can solve the problems of difficult purification, high impurity content, unsuitable for industrial production, etc., and achieve the effects of short reaction time, high purity and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

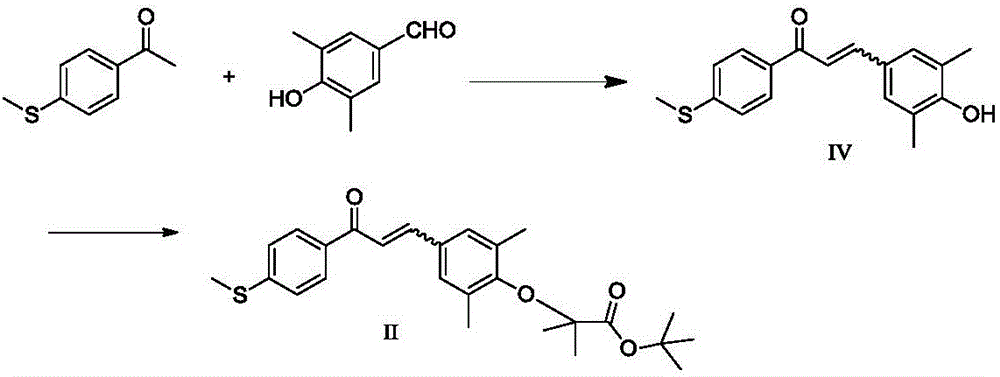

[0036] Example 1: Preparation method of GFT505 intermediate IV (refer to patent WO2011 / 144579)

[0037]

[0038] Add 4-methylmercaptoacetophenone (50g, 0.301mol) and 3,5-dimethyl-4-hydroxybenzaldehyde (45g, 0.301mol) into 200ml hydrogen chloride methanol solution (4mol / L), 20~30℃ Stir for 3 hours, lower the temperature to 0-10° C., stir for 1 hour, filter, and dry to obtain 83 g of GFT505 intermediate (IV) as a yellow solid, with a yield of 93%.

Embodiment 2

[0039] Example 2: Preparation method of GFT505 intermediate IV (refer to patent WO2011 / 144579)

[0040] Add 4-methylmercaptoacetophenone (19Kg, 114mol) and 3,5-dimethyl-4-hydroxybenzaldehyde (17.1Kg, 114mol) into 76L hydrogen chloride methanol solution (4mol / L), and stir at 20-30°C After 3 hours, the temperature was lowered to 0-10°C, stirred for 1 hour, centrifuged, and vacuum-dried at 40°C for 12 hours to obtain 31.6Kg of GFT505 intermediate (IV) as a yellow solid, with a yield of 93%. LCMS: m / z=299 (M+H) + .

Embodiment 3

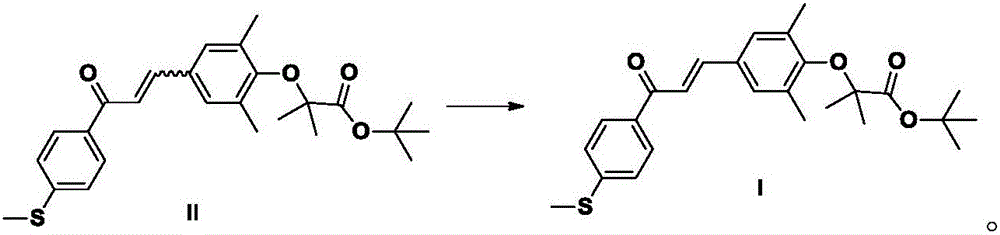

[0041] Embodiment 3: the preparation method of GFT505 intermediate II (reference document US2006 / 142611)

[0042]

[0043] GFT505 intermediate IV (78.8g, 0.263mol) was added to the reaction flask, acetonitrile (480ml) was added, potassium carbonate (54.5g, 0.395mol), tert-butyl 2-bromoisobutyrate (39.3g, 0.176 mol), heated to 75~85°C for 10 hours, added potassium carbonate (54.5g, 0.395mol), and tert-butyl 2-bromoisobutyrate (39.3g, 0.176mol) for 10 hours, then added carbonic acid Potassium (54.5g, 0.395mol), tert-butyl 2-bromoisobutyrate (39.3g, 0.176mol) were reacted for 10 hours until the compound was completely reacted, concentrated under reduced pressure to dryness, added 800g water and 400g dichloromethane, and divided layer, washed with water, the organic phase was dried over anhydrous sodium sulfate, filtered, the organic phase was concentrated to dryness, and recrystallized with ethyl acetate and petroleum ether to obtain 81.1 g of solid compound II with a yield of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap