A kind of preparation method of modified phenolic resin

A phenolic resin and modification technology, which is applied in the chemical field, can solve the problems of complex process and easy pollution of the modified phenolic resin, and achieve the effects of cost reduction and technological progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

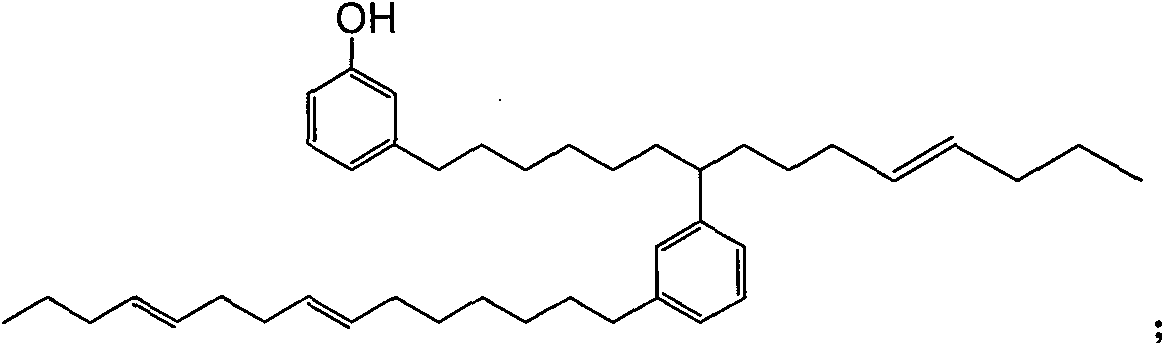

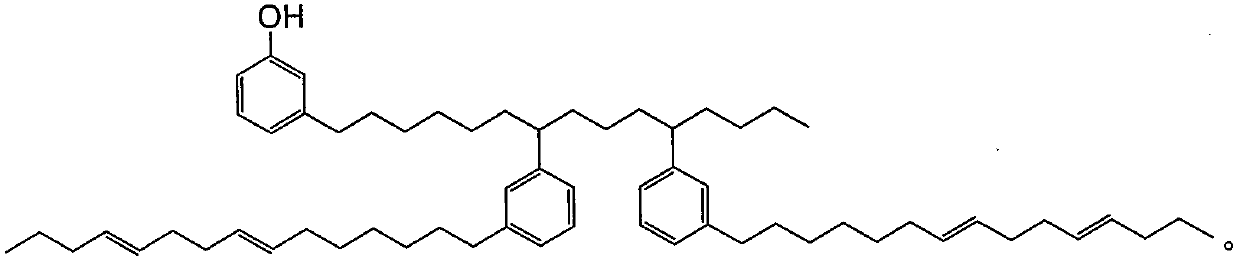

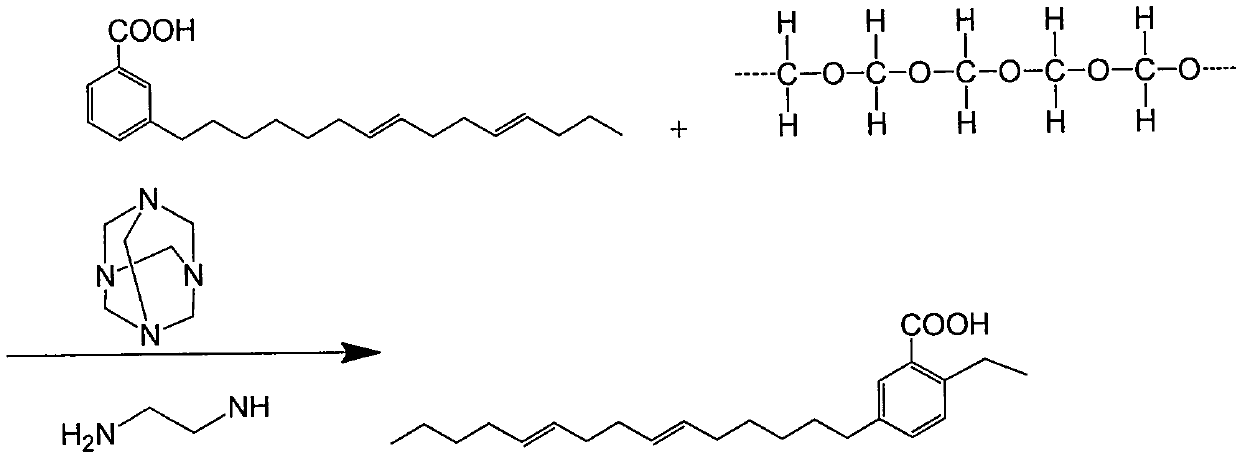

Method used

Image

Examples

Embodiment 1

[0028] 300 grams of heavy phase, 1 gram of urotropine, 21 grams of polyoxymethylene, 4 grams of ethylenediamine, and 30 grams of xylene, add the heavy phase, urotropine, ethylenediamine, and xylene to the reaction bottle, and heat to 50-60°C, add polyoxymethylene in batches, after adding, raise the temperature to 85-95°C, keep it warm for 1 hour, raise the temperature and dehydrate to about 105°C, then vacuum dehydrate, gradually increase the vacuum degree to 0.095MPa, and dehydrate to 120-130°C Keep it for about 30 minutes, add 50 grams of xylene so that the solid content of the resin is between 80% and 90%, stir evenly, and filter out the material. The viscosity is 1972mPa·s, the solid content is 82%, and the yield is 94.18%.

Embodiment 2

[0030] 300 grams of heavy phase, 4 grams of urotropine, 30 grams of polyoxymethylene, 2 grams of ethylenediamine, 50 grams of xylene, add heavy phase, urotropine, ethylenediamine, and xylene in the reaction bottle, and heat to 50-60°C, add polyoxymethylene in batches, after adding, raise the temperature to 85-95°C, keep it warm for 1 hour, raise the temperature and dehydrate to about 105°C, then vacuum dehydrate, gradually increase the vacuum degree to 0.095MPa, and dehydrate to 120-130°C Keep it for about 30 minutes, add 50 grams of xylene so that the solid content of the resin is between 80% and 90%, stir evenly, and filter out the material. The viscosity is 3350mPa·s, the solid content is 89.77%, and the yield is 93.58%.

Embodiment 3

[0032] 300 grams of heavy phase, 4 grams of urotropine, 45 grams of polyoxymethylene, 4 grams of ethylenediamine, and 80 grams of xylene, add heavy phase, urotropine, ethylenediamine, and xylene to the reaction bottle, and heat to 50-60°C, add polyoxymethylene in batches, after adding, raise the temperature to 85-95°C, keep it warm for 1 hour, raise the temperature and dehydrate to about 105°C, then vacuum dehydrate, gradually increase the vacuum degree to 0.095MPa, and dehydrate to 120-130°C Keep it for about 30 minutes, add 50 grams of xylene so that the solid content of the resin is between 80% and 90%, stir evenly, and filter out the material. The viscosity is 3050mPa·s, the solid content is 89.567%, and the yield is 95.58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com