Thermally conductive hexagonal boron nitride hybrid material and its preparation method and application

A hexagonal boron nitride and mixing technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, fibrous fillers, etc., can solve the problems of unsatisfactory thermal conductivity and heat resistance, unstable thermal conductivity, etc., and achieve improved Stability of work, stable thermal conductivity, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

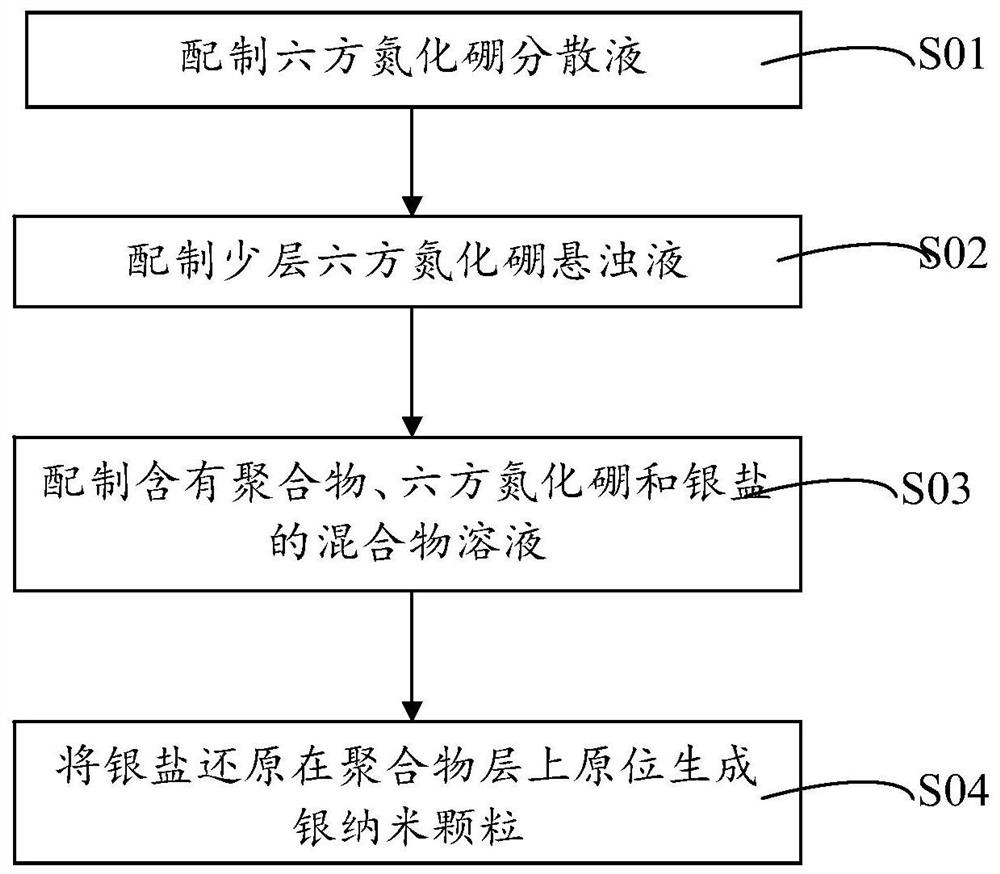

[0029] Correspondingly, an embodiment of the present invention also provides a method for preparing the heat-conducting hexagonal boron nitride hybrid material described above. The process of the preparation method is as follows figure 1 shown, including the following steps:

[0030] S01. Prepare a hexagonal boron nitride dispersion: disperse hexagonal boron nitride in a solvent to prepare a hexagonal boron nitride dispersion;

[0031] S02. Prepare a few-layer hexagonal boron nitride suspension: perform a first centrifugation on the hexagonal boron nitride dispersion to collect the upper dispersion; then perform a second centrifugal separation on the upper dispersion to collect the precipitate and carry out drying treatment, and then prepare the dried precipitate into hexagonal boron nitride suspension;

[0032] S03. Prepare a mixture solution containing polymer, hexagonal boron nitride and silver salt: add polymer to the hexagonal boron nitride suspension for mixing treatme...

Embodiment 1

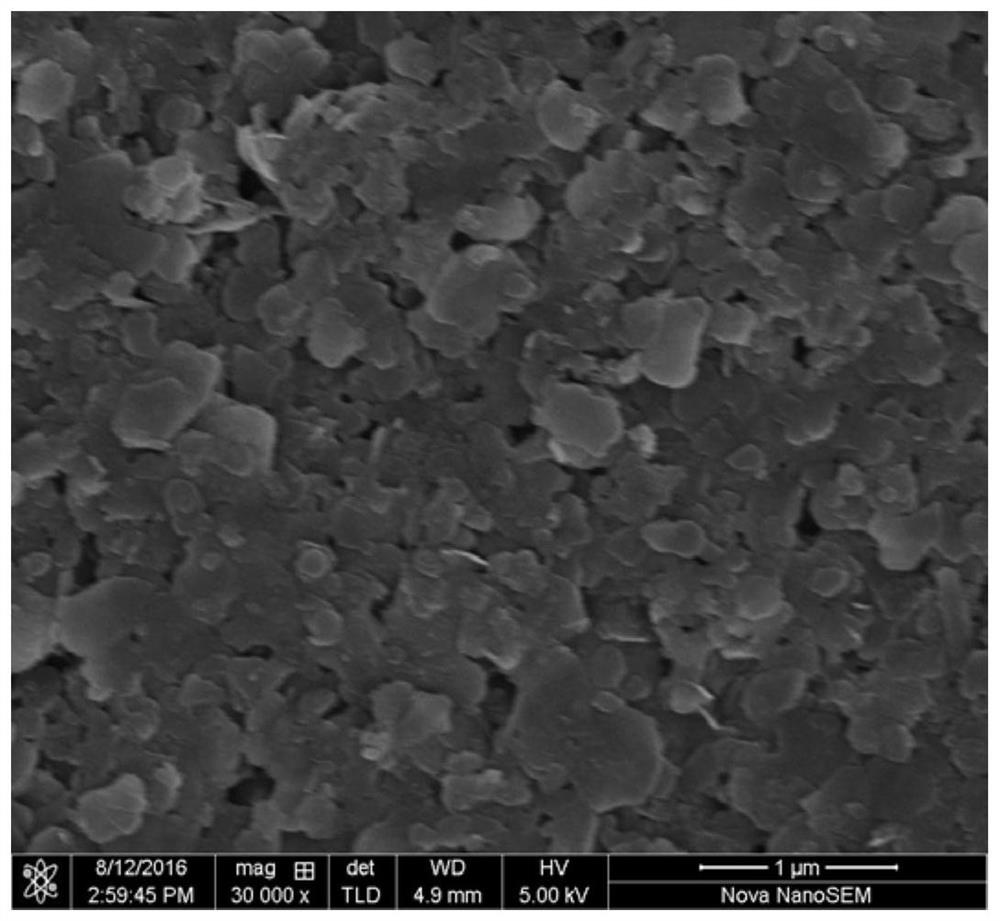

[0048] The invention provides a thermally conductive hexagonal boron nitride hybrid material, which includes hexagonal boron nitride (h-BN) and a polymer layer coated on the hexagonal boron nitride, and the polymer layer is loaded with silver nanoparticles.

[0049] Its preparation method is as follows:

[0050] S11. Stripping of hexagonal boron nitride:

[0051] Mix 2g h-BN and 300ml N-methylpyrrolidone in a 500ml jar, and disperse ultrasonically for 24 hours at room temperature; put the mixed solution after ultrasonic treatment into a 50ml centrifuge tube and centrifuge at 3000rpm in a desktop high-speed centrifuge Finally, take the upper layer solution to obtain a thinner h-BN mixed solution. The obtained h-BN mixed solution with thinner sheets was centrifuged at 10,000 rpm, and the bottom precipitate was collected, washed, and dried to obtain 1.2 g of h-BN with thinner sheets after peeling off.

[0052] S12. Linear polymer coated h-BN:

[0053] Take 0.1g of h-BN with a...

Embodiment 2

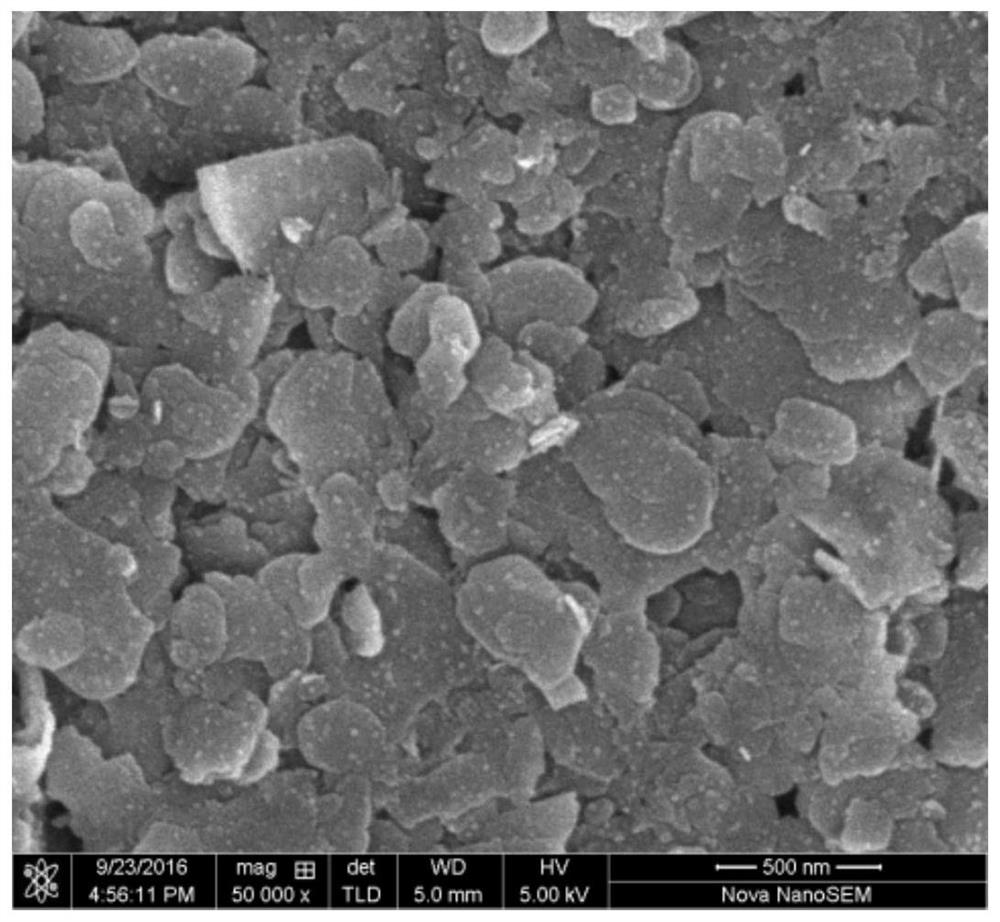

[0058] The present invention provides a thermally conductive hexagonal boron nitride hybrid material, the structure of which is the same as that of the thermally conductive hexagonal boron nitride hybrid material in Embodiment 1.

[0059] Its preparation method is as follows:

[0060] S21. Stripping of hexagonal boron nitride:

[0061] Mix 2g h-BN and 300ml N-methylpyrrolidone in a 500ml jar, and ultrasonically disperse at room temperature for 24h. Put the mixed solution after ultrasonic treatment into a 50ml centrifuge tube and centrifuge at a speed of 3000rpm in a desktop high-speed centrifuge, then take the upper layer solution to obtain a thinner h-BN mixed solution. The obtained h-BN mixed solution with thinner sheets was centrifuged at a speed of 10000rpm, and the bottom precipitate was taken, washed and dried to obtain 1.2g of h-BN with thinner sheets after peeling off;

[0062] S22. Linear polymer coated h-BN:

[0063] Take 0.1 g of h-BN with a thin layer and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com