Steel band reinforced antibacterial PE (polyethylene) water supply pipe and preparation method thereof

A technology for water supply pipes and steel strips, applied in the field of pipelines, can solve problems such as easy formation of scale, adhesion or breeding of microorganisms, low impact resistance and compressive strength, and impact on people's health, so as to achieve firm and reliable connection performance and high production efficiency , good overall strength and anti-explosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

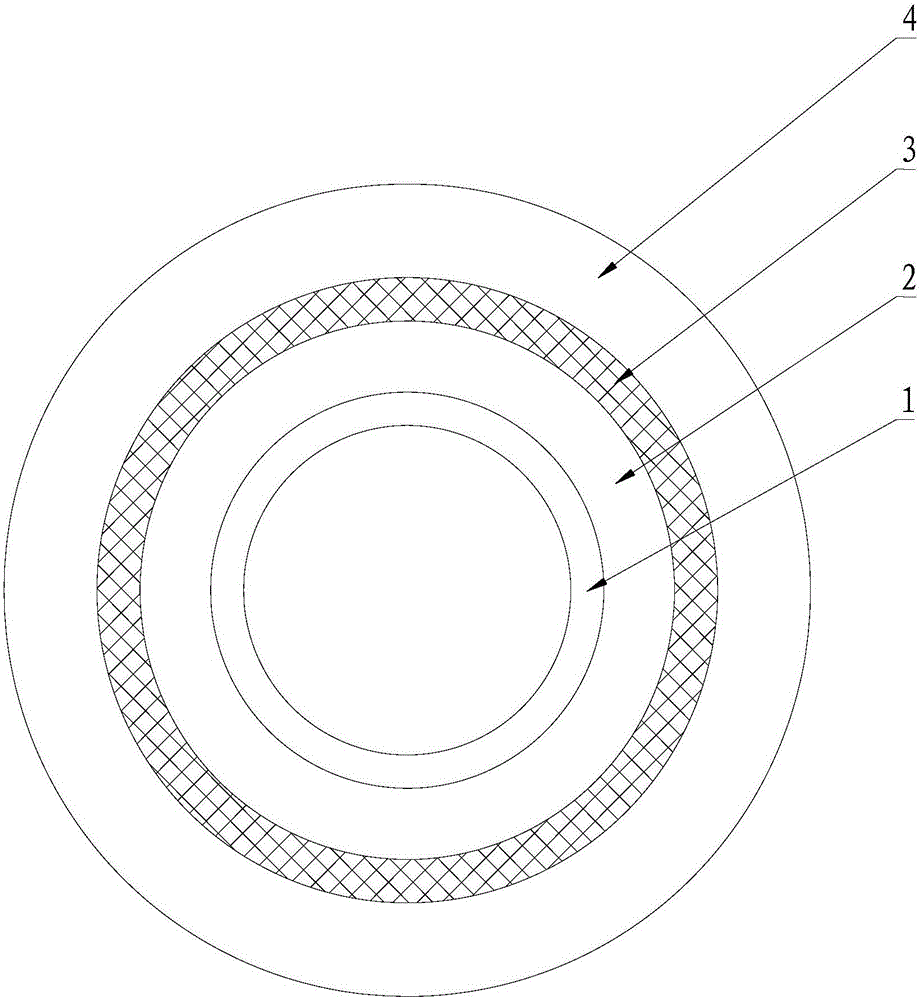

[0031] Please continue to refer figure 1 As shown, the preparation method of the steel belt reinforced antibacterial PE water supply pipe provided by the present invention includes:

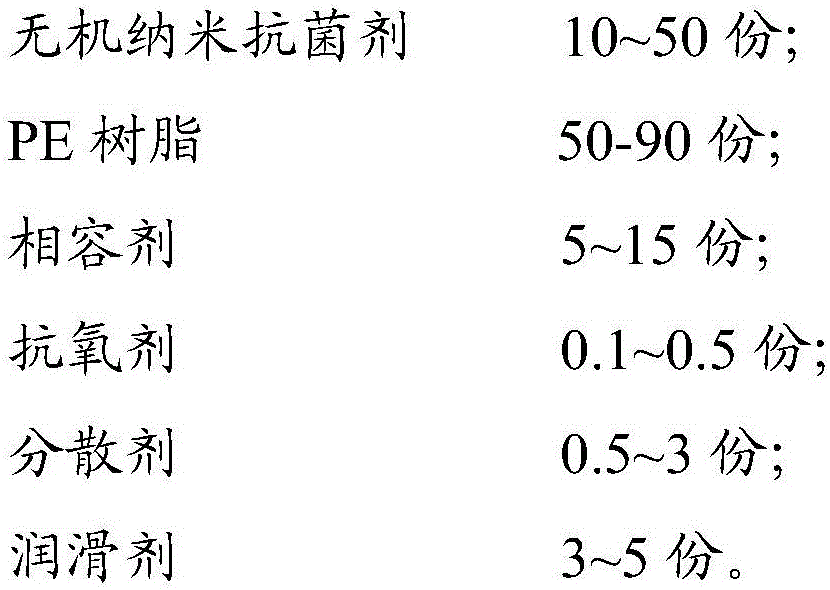

[0032] S1. Weigh the components by weight according to the following formula:

[0033]

[0034] S2. Put the above-mentioned components in a high-mixer and mix and stir for 5-10 minutes, and then melt and extrude and pelletize through a twin-screw extruder to obtain the antibacterial layer raw material. The extrusion process is: a zone temperature of 100°C, Zone temperature 130°C, zone three temperature 160°C, zone four temperature 170°C, zone five temperature 175°C, zone six temperature 175°C, zone seven temperature 170°C, head temperature 170°C, host speed during extrusion: 400~480r / min; feeding speed 30~38r / min;

[0035] S3. The inner PE layer is pre-coated on the steel belt layer, and the antibacterial layer and the outer PE layer are respectively extruded on the inner and outer sides of the steel...

Embodiment 1

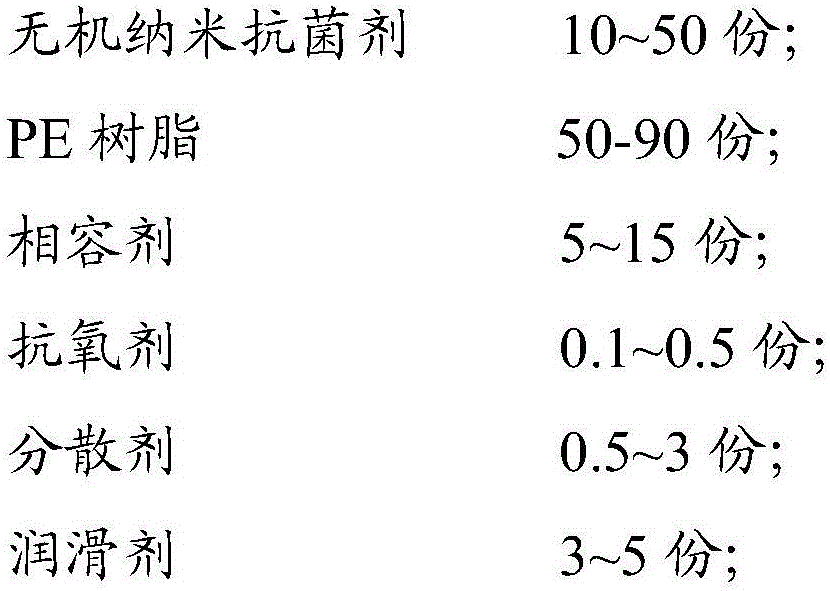

[0048] (1) Weigh out the components by weight according to the following formula:

[0049]

[0050]

[0051] (2) Place the above components in a high-mixer and stir for 5-10 minutes;

[0052] (3) The mixture obtained in step (2) is melt-extruded and pelletized by a twin-screw extruder. The process conditions are: temperature in the first zone is 100°C, temperature in the second zone is 130°C, temperature in the third zone is 160°C, and temperature in the fourth zone 170℃, temperature of five zone 175℃, temperature of six zone 175℃, temperature of seven zone 170℃, head temperature 170℃, main engine speed during extrusion: 400r / min; feeding speed 30r / min.

[0053] (4) By pre-coating the inner PE layer on the steel strip layer, and then extruding the antibacterial layer and the outer PE layer on both the inner and outer sides of the pre-coated steel strip layer, by controlling the temperature, pressure and time during the production and molding process The parameters ensure that the st...

Embodiment 2

[0055] (1) Weigh out the components by weight according to the following formula:

[0056]

[0057] (2) Place the above components in a high-mixer and stir for 5-10 minutes;

[0058] (3) The mixture obtained in step (2) is melt-extruded and pelletized by a twin-screw extruder. The process conditions are: temperature in the first zone is 100°C, temperature in the second zone is 130°C, temperature in the third zone is 160°C, and temperature in the fourth zone 170℃, temperature of five zone 175℃, temperature of six zone 175℃, temperature of seven zone 170℃, head temperature 170℃, main engine speed during extrusion: 430r / min; feeding speed 33r / min.

[0059] (4) By pre-coating the inner PE layer on the steel strip layer, and then extruding the antibacterial layer and the outer PE layer on both the inner and outer sides of the pre-coated steel strip layer, by controlling the temperature, pressure and time during the production and molding process The parameters ensure that the steel and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com