Cast-in-situ ardealite based early strength fireproof composite wallboard and preparation method thereof

A technology of cast-in-place phosphogypsum and composite wallboard, applied in building materials and other directions, can solve the problems of not being able to further meet the requirements of light weight, fire prevention, easy construction, increasing the turnover cost of formwork, poor fire resistance, etc. Compressive strength and softening coefficient, the effect of strength guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

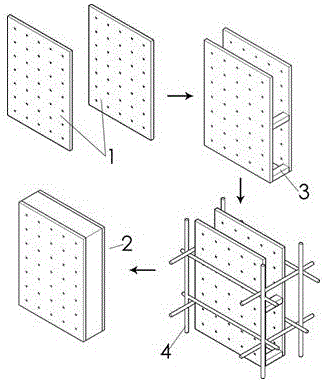

[0037] The preparation method of cast-in-place phosphogypsum-based early-strength fireproof composite wallboard comprises the following steps:

[0038] (1) Manufacture and support of calcium silicate board:

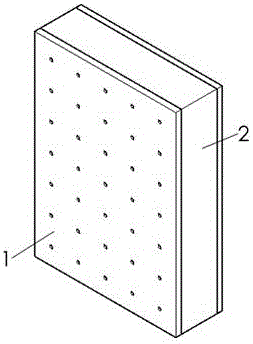

[0039] A. According to the experimental wall size of 1500mm×1500mm×120mm, cut out two calcium silicate boards with the same size as the largest wall area of 1500mm×1500mm;

[0040] B. Drill holes on two calcium silicate boards, the required hole size is 2mm, and the horizontal and vertical spacing between each hole is 50mm;

[0041] C. Place a β-type phosphorus building plaster block at the corner between the two calcium silicate boards and at the middle of the edge of the calcium silicate board. The size of the block is consistent with the design thickness of the cast-in-place wall, which is 120mm×80mm× 60mm block, brush the adhesive on the contact surface of the block and the calcium silicate board; then, set up scaffolding to clamp and fix the two calcium silicate b...

Embodiment 2

[0057] The preparation method of cast-in-place phosphogypsum-based early-strength fireproof composite wallboard comprises the following steps:

[0058] (1) Manufacture and support of calcium silicate board:

[0059] A. According to the experimental wall size of 2000mm×1000mm×120mm, cut out two calcium silicate boards with the same size as the largest wall area of 20000mm×1000mm;

[0060] B. Drill holes on two calcium silicate boards, the required aperture size is 3mm, and the horizontal and vertical spacing between each hole is 50mm;

[0061] C. Place a β-type phosphorus building plaster block at the corner between the two calcium silicate boards and at the middle of the edge of the calcium silicate board. The size of the block is consistent with the design thickness of the cast-in-place wall, which is 120mm×80mm× 60mm block, brush the adhesive on the contact surface of the block and the calcium silicate board; then, set up scaffolding to clamp and fix the two calcium silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com