Two-dimensional material flexible substrate structure, semiconductor light emitting device and manufacturing method thereof

A flexible substrate and two-dimensional material technology, applied in the semiconductor field, can solve the problem that the flexible substrate cannot fully absorb and release stress, and achieve the effects of increasing device integration functions, reducing costs, and expanding wavelengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

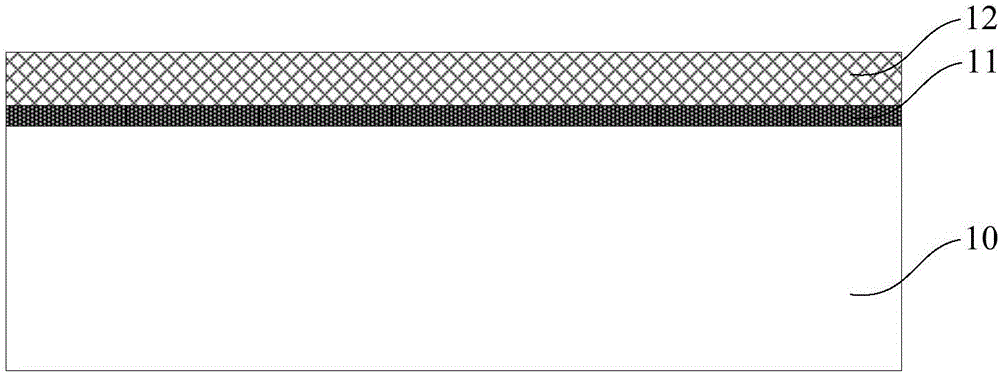

[0071] see figure 1 , the present invention provides a two-dimensional material flexible substrate structure, the two-dimensional material flexible substrate structure includes: a supporting substrate 10; a two-dimensional material layer 11, the two-dimensional material layer 11 is located on the supporting substrate 10 surface; a flexible substrate 12, the flexible substrate 12 is located on the surface of the two-dimensional material layer 11.

[0072] As an example, the supporting substrate 10 may be a semiconductor substrate, a semi-insulator substrate, an insulator substrate, or a thermally conductive material substrate. Preferably, in this embodiment, the supporting substrate 10 is a Si substrate.

[0073] As an example, the two-dimensional material layer 11 may be a graphene layer, a silicene layer, a germanene layer, a BN layer, MoS 2 Layer or WS 2 layer. Preferably, in this embodiment, the two-dimensional material layer 11 is a graphene layer.

[0074] As an exam...

Embodiment 2

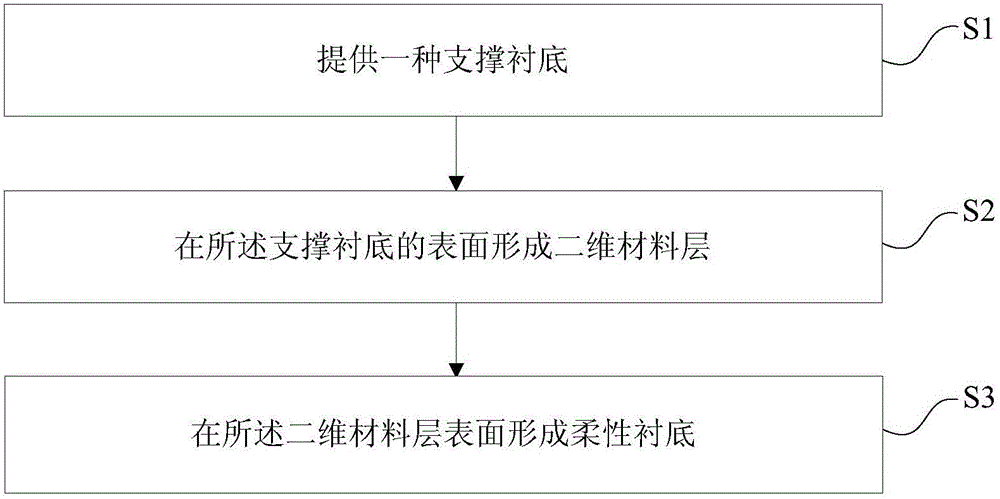

[0078] see figure 2 , the present invention also provides a method for manufacturing a two-dimensional material flexible substrate structure, the method for manufacturing a two-dimensional material flexible substrate structure includes the following steps:

[0079] 1) providing a support substrate;

[0080] 2) forming a two-dimensional material layer on the surface of the supporting substrate;

[0081] 3) Forming a flexible substrate on the surface of the two-dimensional material layer.

[0082] To perform step 1), see figure 2 Step S1 in and image 3 , providing a support substrate 10 .

[0083] As an example, the supporting substrate 10 may be a semiconductor substrate, a semi-insulator substrate, an insulator substrate, or a thermally conductive material substrate. Preferably, in this embodiment, the supporting substrate 10 is a Si substrate.

[0084] Execute step 2), see figure 2 Step S2 in and Figure 4 , forming a two-dimensional material layer 11 on the surfa...

Embodiment 3

[0100] see Figure 11 and Figure 12, the present invention also provides a semiconductor light emitting device, the semiconductor light emitting device includes: the two-dimensional material flexible substrate structure described in Embodiment 1 and a light emitting device material layer 17, the light emitting device material layer 17 is located on the flexible the surface of the substrate. For the specific structure of the two-dimensional material flexible substrate structure, please refer to Embodiment 1, which will not be repeated here.

[0101] see Figure 11 , in an example, the light emitting device material layer includes: a lower electrode 171, the lower electrode 171 is located on the surface of the flexible substrate 12; a lower waveguide layer 172, the lower waveguide layer 172 is located on the lower electrode 171 The surface of the quantum well layer 173, the quantum well layer 173 is located on the surface of the lower waveguide layer 172, and the quantum wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com