Canned chewing cane and manufacturing method thereof

A production method and technology of fruit cane, which is applied in the direction of fruit and vegetable preservation, food ingredients as taste improvers, food ingredients as taste improvers, etc., can solve problems such as inability to form industrialized production, undisclosed production process, and inability to preserve for a long time , to achieve the effect of convenient operation, quality improvement and healthier taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

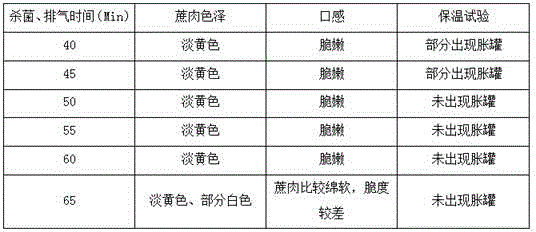

Examples

Embodiment 1

[0040] A kind of canned fruit cane, comprising the following raw materials in parts by weight:

[0041] Fruit cane 40, white sugar 5, pure sesame oil 4, soybean 10, sea salt 1, cane juice 20.

[0042] Described canned fruit cane, its preparation method comprises the following steps:

[0043] ①Choose high-quality fruit cane with thin skin, crisp stem, juicy, sweet, crisp, tender and refreshing taste, peel and wash;

[0044] ②Cut off the cane nodes first, slice them longitudinally along the length of the fruit cane, cut the cane meat between the two cane nodes obliquely three times, and cut them into uniform oblique pieces of fruit cane; the cut cane nodes are squeezed into sugarcane juice;

[0045] ③ Add 20g of dry salt per 100g of fruit cane and mix directly, the salting time is 3-5 days, after desalination, use a mass concentration of 0.6%-1.0%CaCl 2 The solution is immersed for 1-2 hours for hardening treatment;

[0046] ④ Pour the processed fruit cane pieces in step ③ into...

Embodiment 2

[0053] A kind of canned fruit cane, comprising the following raw materials in parts by weight:

[0054] Fruit cane 50, white sugar 7.5, pure sesame oil 4.5, soybean 12.5, sea salt 2, cane juice 25.

[0055] Described canned fruit cane, its preparation method comprises the following steps:

[0056] ①Choose high-quality fruit cane with thin skin, crisp stem, juicy, sweet, crisp, tender and refreshing taste, peel and wash;

[0057] ②Cut off the cane nodes first, slice them longitudinally along the length of the fruit cane, cut the cane meat between the two cane nodes obliquely three times, and cut them into uniform oblique pieces of fruit cane; the cut cane nodes are squeezed into sugarcane juice;

[0058] ③ Add 20g of dry salt per 100g of fruit cane and mix directly, the salting time is 3-5 days, after desalination, use a mass concentration of 0.6%-1.0%CaCl 2 The solution is immersed for 1-2 hours for hardening treatment;

[0059] ④ Pour the processed fruit cane pieces in ste...

Embodiment 3

[0066] A kind of canned fruit cane, comprising the following raw materials in parts by weight:

[0067] Fruit cane 60, white sugar 10, pure sesame oil 5, soybean 15, sea salt 3, cane juice 30.

[0068] Described canned fruit cane, its preparation method comprises the following steps:

[0069] ①Choose high-quality fruit cane with thin skin, crisp stem, juicy, sweet, crisp, tender and refreshing taste, peel and wash;

[0070] ②Cut off the cane nodes first, slice them longitudinally along the length of the fruit cane, cut the cane meat between the two cane nodes obliquely three times, and cut them into uniform oblique pieces of fruit cane; the cut cane nodes are squeezed into sugarcane juice;

[0071] ③ Add 20g of dry salt per 100g of fruit cane and mix directly, the salting time is 3-5 days, after desalination, use a mass concentration of 0.6%-1.0%CaCl 2 The solution is immersed for 1-2 hours for hardening treatment;

[0072] ④ Pour the processed fruit cane pieces in step ③ i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com