Gas sterilization device and method

A sterilization device and gas technology, applied in water supply devices, disinfection, construction, etc., can solve the problems of long sterilization cycle time, corrosion residue of items, poor diffusivity, etc., and achieve shortened operation time, short sterilization time, and clearing time fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

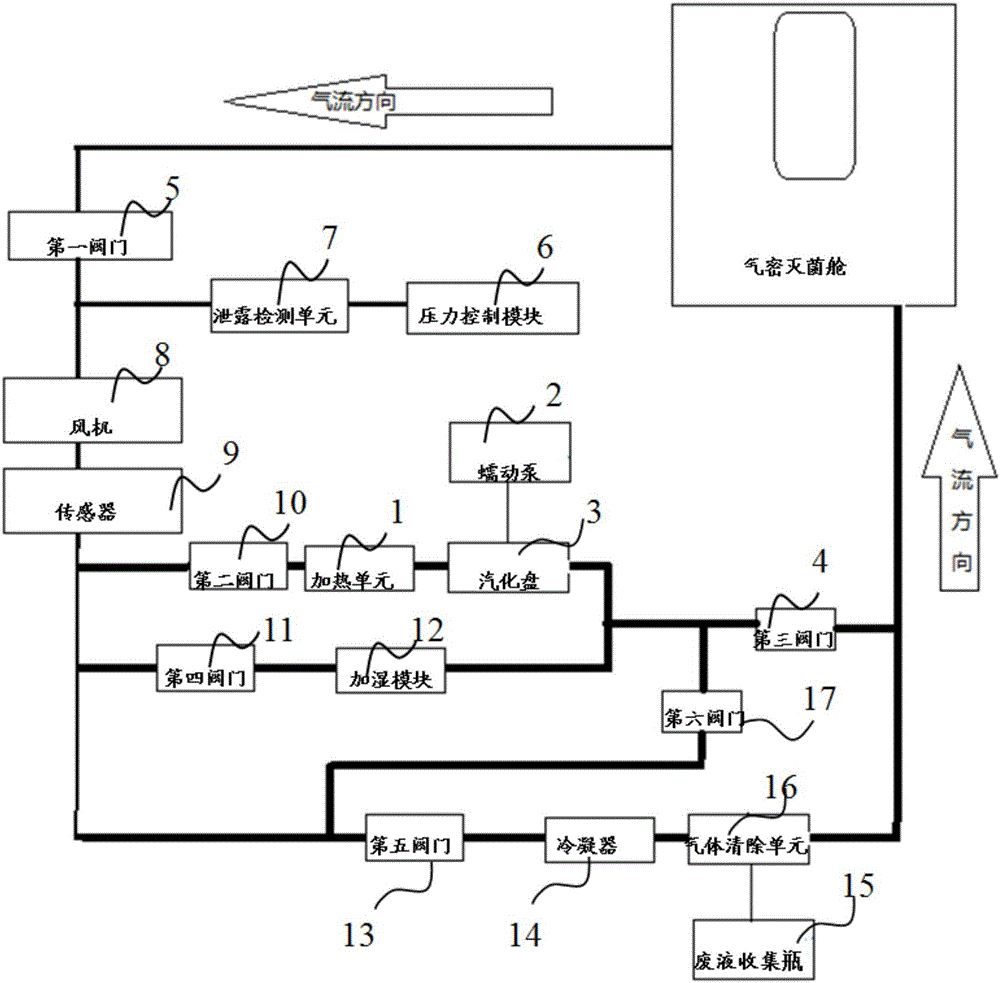

[0039] Such as figure 1 As shown, a gas sterilizing device according to the embodiment of the present invention includes a gas generator, a humidification module 12, a pressure control module 6, a sensor 9 and a PLC control module, and the gas outlet of the gas generator is connected to the airtight sterilization chamber. The air inlet end is connected, and the gas outlet end of the airtight sterilization chamber is connected with the sensor 9, and the gas generator, the airtight sterilization chamber and the sensor 9 form a first loop; the PLC control module controls the gas generator, the airtight sterilization chamber, and the sensor respectively. Humidification module 12 and pressure control module 6.

[0040] In the above-mentioned gas sterilization device, the gas generated by the gas generator is transported to the airtight sterilization chamber through pipelines, and the airtight sterilization chamber is sterilized and disinfected. Wherein, the PLC control module can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com