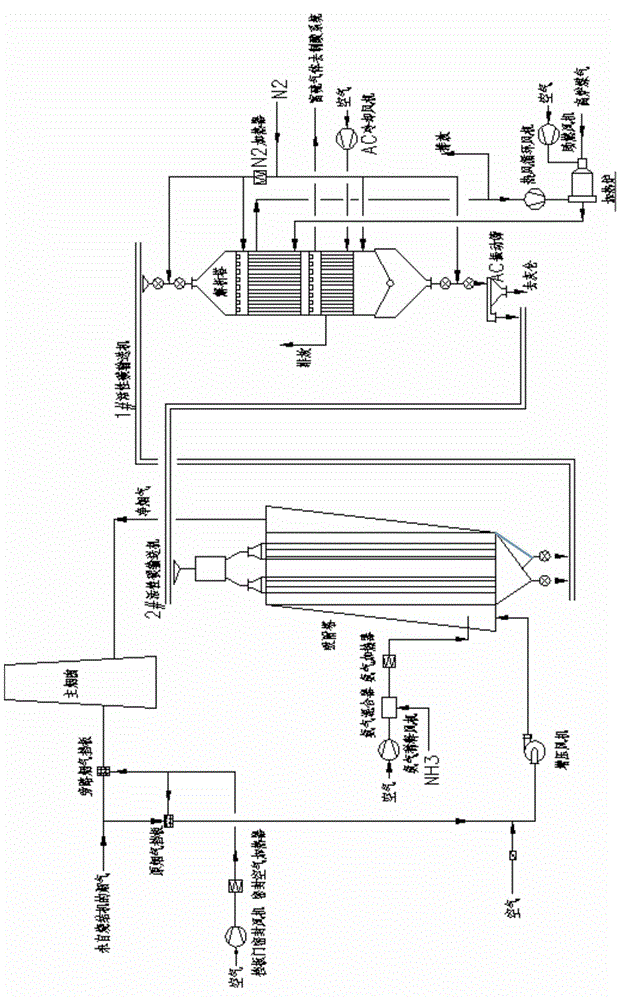

Activated carbon method flue gas cleaning device and flue gas cleaning method

A purification device and flue gas purification technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of increasing investment and operating costs, increasing equipment maintenance workload, and failing to purify flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

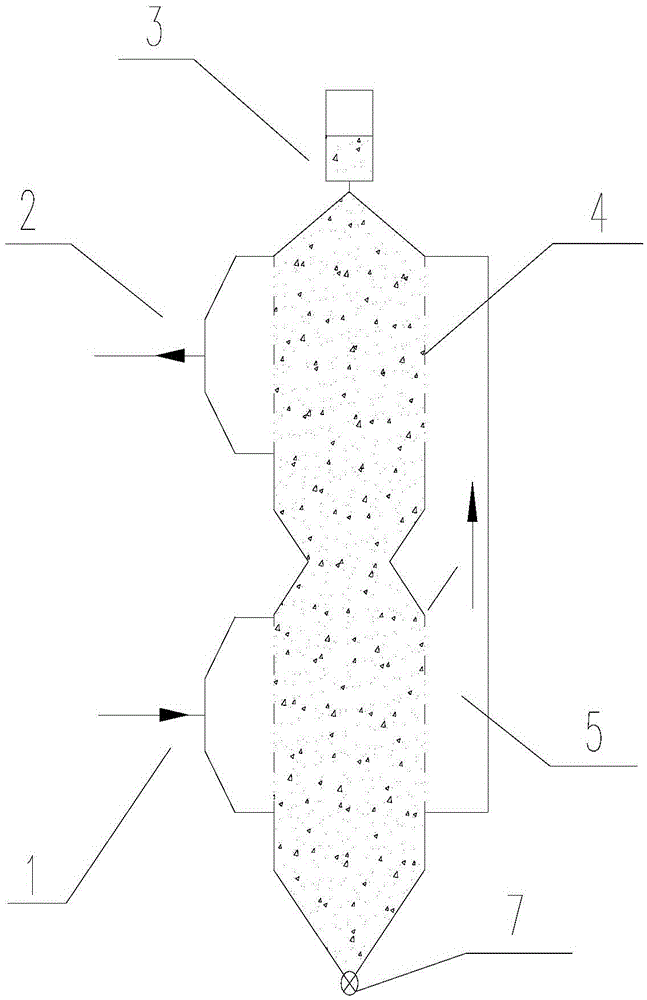

[0083] Adsorption tower such as Figure 4 shown. Desulfurization and denitrification devices include activated carbon adsorption tower (tower height 30 meters, cross-sectional area 120m 2 ) and analytical tower (tower height 20 meters, cross-sectional area 15m 2 ).

[0084] The lower activated carbon bed part A has three activated carbon chambers a1 , a2 and a3 and the upper activated carbon bed part B has three activated carbon chambers b1 , b2 and b3 .

[0085] Along the airflow direction, according to the sequence of each layer of activated carbon contacting the flue gas, each layer is defined as the lower anterior chamber, middle chamber, and rear chamber; the upper anterior chamber, middle chamber, and rear chamber. The thickness of the front, middle and rear chambers of the lower layer are 150mm, 450mm, 900mm respectively, and the total thickness is 1500mm; The activated carbon residence time in the back chamber is, for example, 40h, 120h, 240h.

[0086] The upper a...

Embodiment 2

[0093] Adsorption tower such as Figure 5 shown. For flue gas with little fluctuation in pollutant composition, the roller feeder for upper layer unloading can be eliminated, and the residence time of materials in each layer can be realized by controlling the width of each chamber on the upper and lower layers. The height of the transition zone (C) of the adsorption tower or the length of the transition zone (C) of the adsorption tower in the vertical direction is 3m.

[0094] Along the airflow direction, according to the sequence of each layer of activated carbon contacting the flue gas, each layer is defined as the lower anterior chamber, middle chamber, and rear chamber; the upper anterior chamber, middle chamber, and rear chamber. The thickness of the front, middle and rear chambers of the lower layer are 150mm, 450mm, 900mm respectively, and the total thickness is 1500mm; The activated carbon residence time in the back chamber is, for example, 40h, 120h, 240h.

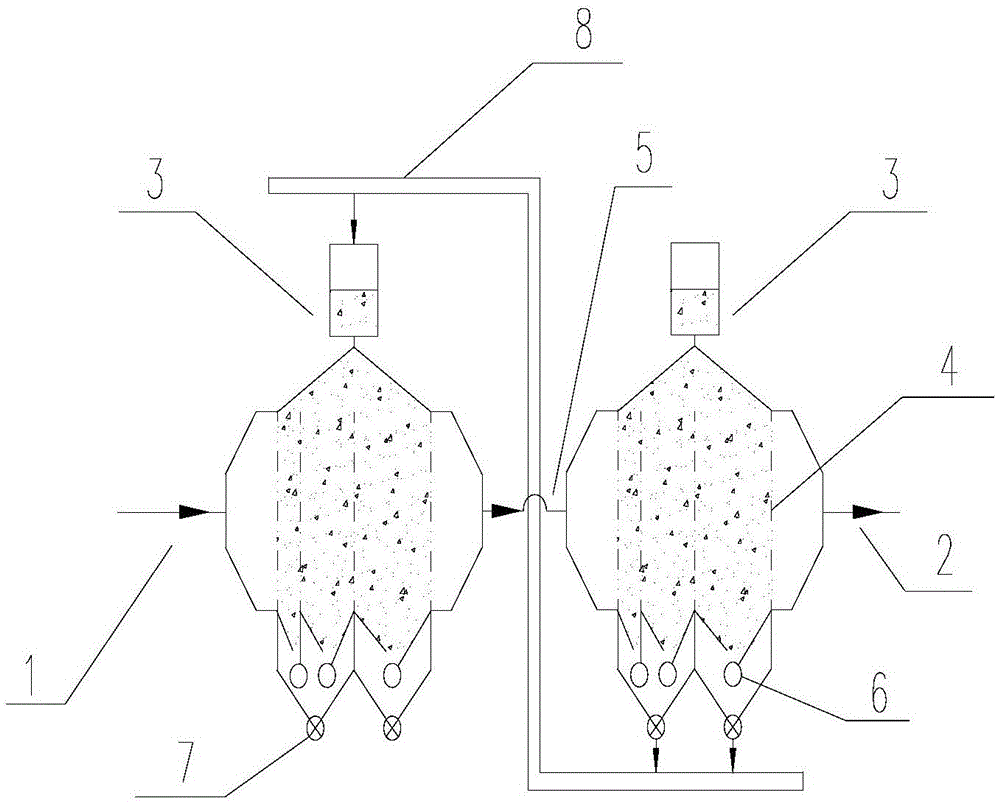

Embodiment 3

[0096] Adsorption tower such as Image 6 shown. In order to reduce the initial filling amount of activated carbon, reduce investment costs, and at the same time reduce the residence time of activated carbon that has not been in contact with flue gas in the tower, the length of the activated carbon channel between the upper and lower layers can be reduced.

[0097] Along the airflow direction, according to the sequence of each layer of activated carbon contacting the flue gas, each layer is defined as the lower anterior chamber, middle chamber, and rear chamber; the upper anterior chamber, middle chamber, and rear chamber. The thickness of the front, middle and rear chambers of the lower layer are 150mm, 450mm, 900mm respectively, and the total thickness is 1500mm; The activated carbon residence time in the back chamber is, for example, 40h, 120h, 240h.

[0098] The middle activated carbon passage 10 is an invalid area, so under the premise of ensuring the feeding speed of ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com