Efficient molybdenum spraying device

A high-efficiency, drying device technology, applied in the direction of spraying device, liquid spraying device, melt spraying, etc., can solve the problems that the adjustment frame cannot meet the work requirements, the angle of spraying is reduced, and the spraying effect is poor, so as to reduce the Masking effect, avoid powder needle clogging, and reduce the effect of coating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

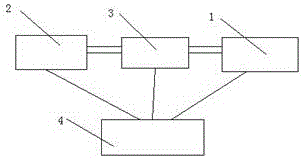

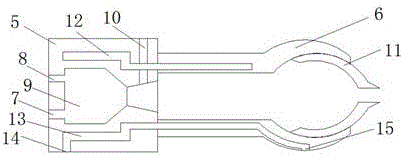

[0017] Such as Figure 1-2 As shown, a high-efficiency molybdenum spraying device of this embodiment includes a spray gun 1, a powder feeder 2, a drying device 3 and a control system 4, the powder feeder 2 is connected to the spray gun 1 through a pipeline, and the drying device 3 is set on the pipeline between the powder feeder 2 and the spray gun 1, the spray gun 1, the powder feeder 2 and the drying device 3 are all electrically connected to the control system 4, and the spray gun 1 includes a gun body 5 and a gun barrel 6. The gun barrel 6 is installed on one end face of the gun body 5, and the end face of the gun body 5 away from the gun barrel 6 is provided with a fuel inlet 7 and an air inlet 8, and a combustion chamber is arranged inside the gun body 5 9. The combustion chamber 9 communicates with the fuel inlet 7 and the air inlet 8, the outlet of the combustion chamber 9 communicates with the gun barrel 6, and the side of the gun body 5 has a powder inlet channel 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com