A kind of preparation method of ammonium propionate crystal and powder thereof

A technology of ammonium propionate and propionic acid, which is applied in the preparation of carboxylate, carboxylate, and organic compounds, etc., can solve the problems of immature preparation process, difficult purification of products, complex process, etc., and achieve good palatability, The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

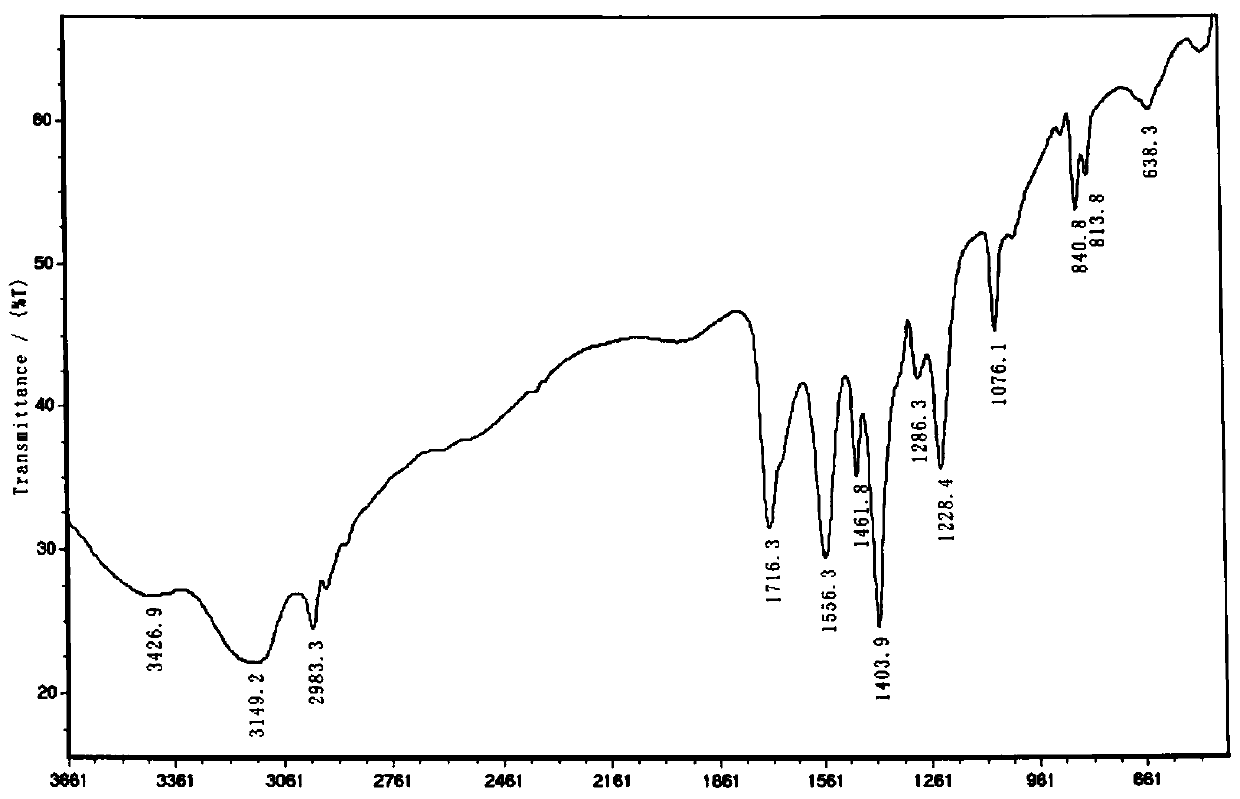

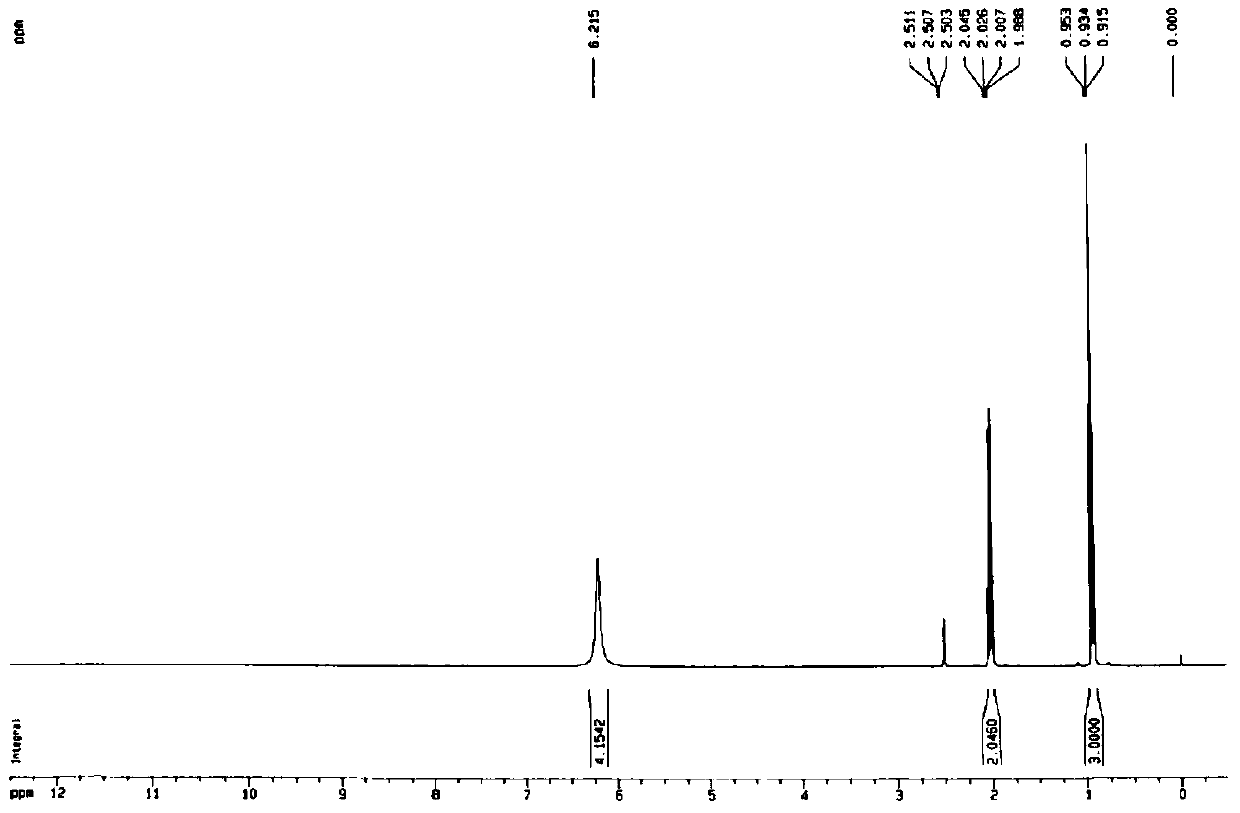

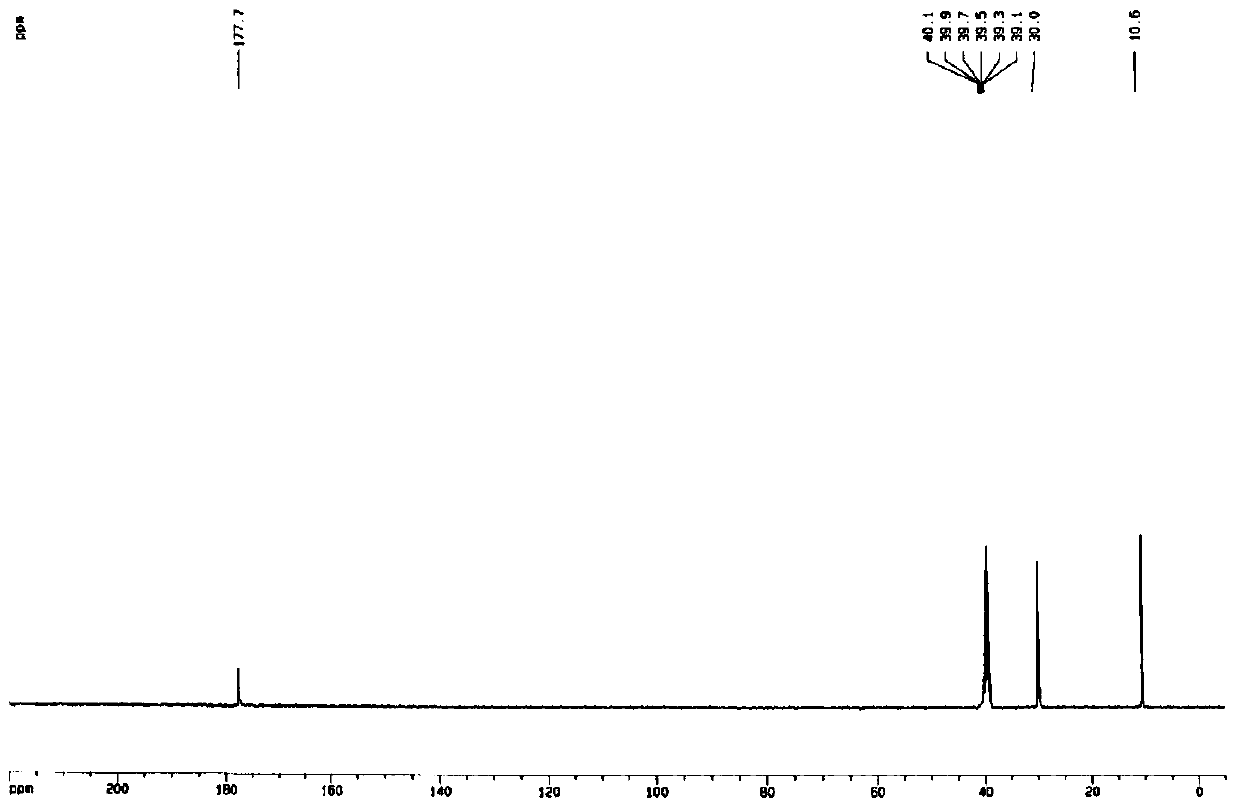

Image

Examples

Embodiment 1

[0035] This example is used to illustrate the preparation method of the ammonium propionate crystal provided by the present invention. Proceed as follows:

[0036] 1) Add 600kg propionic acid to a volume of 1m 3 The first reactor, 700kg propionic acid added volume is 1m 3 The second reactor, 700kg propionic acid added volume is 1m 3 In the third reactor, the first reactor is a main reaction device, the second reactor is a primary ammonia tail gas absorption device, the third reactor is a secondary ammonia absorption device, and the main reaction device , one-level ammonia tail gas absorption device and secondary ammonia tail gas absorption device are connected in sequence; and the propionic acid in the main reaction device and the first-level ammonia tail gas absorption device is stirred; in the present embodiment, the main reaction device is the main reaction The first-level ammonia tail gas absorption device is the first-level ammonia tail gas absorption tank, and the sec...

Embodiment 2

[0044] This example is used to illustrate the preparation method of the ammonium propionate crystal provided by the present invention. Proceed as follows:

[0045]1) Add 650kg propionic acid to a volume of 1m 3 The first reactor, 750kg propionic acid added volume is 1m 3 The second reactor, 750kg propionic acid added volume is 1m 3 In the third reactor, the first reactor is a main reaction device, the second reactor is a primary ammonia tail gas absorption device, the third reactor is a secondary ammonia absorption device, and the main reaction device , one-level ammonia tail gas absorption device and secondary ammonia tail gas absorption device are connected in sequence; and the propionic acid in the main reaction device and the first-level ammonia tail gas absorption device is stirred; in the present embodiment, the main reaction device is the main reaction The first-level ammonia tail gas absorption device is the first-level ammonia tail gas absorption tank, and the seco...

Embodiment 3

[0053] This example is used to illustrate the preparation method of the ammonium propionate crystal provided by the present invention. Proceed as follows:

[0054] 1) Add 700kg propionic acid to a volume of 1m 3 The first reactor, 800kg propionic acid added volume is 1m 3 The second reactor, 800kg propionic acid added volume is 1m 3 In the third reactor, the first reactor is a main reaction device, the second reactor is a primary ammonia tail gas absorption device, the third reactor is a secondary ammonia absorption device, and the main reaction device , one-level ammonia tail gas absorption device and secondary ammonia tail gas absorption device are connected in sequence; and the propionic acid in the main reaction device and the first-level ammonia tail gas absorption device is stirred; in the present embodiment, the main reaction device is the main reaction The first-level ammonia tail gas absorption device is the first-level ammonia tail gas absorption tank, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com