Polyethylene for rotational moulding and preparation method thereof

A technology of polyethylene and polyethylene resin, which is applied in the field of polyethylene processing, can solve problems such as foaming process and drop performance detection not mentioned, and achieve excellent drop performance, enhanced impact resistance and drop resistance, and good plasticization effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Examples 1 to 5 are specific implementations of polyethylene for rotomoulding and its preparation method of the present invention. Wherein embodiment 1 is the best implementation mode.

Embodiment 1~5

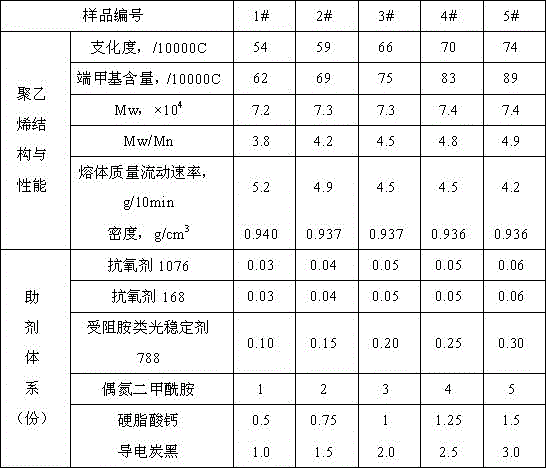

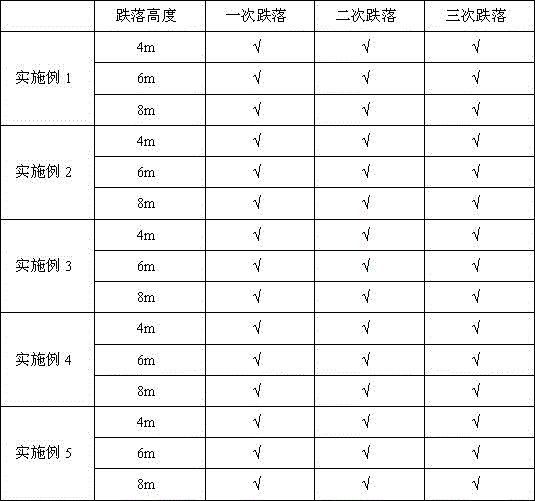

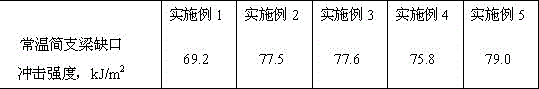

[0035] Examples 1-5 can obtain polyethylene powders with different degrees of branching, terminal methyl content, molecular weight, melt mass flow rate and density by changing the addition amount of hexene-1 and the control of polymerization reaction temperature and pressure. The polyethylene for rotomolding of the present invention is obtained by the above-mentioned preparation method with the preferred auxiliary agent formula. The structural performance characteristics and additive system of special structure polyethylene powder are shown in Table 1.

[0036] Table 1 Example 1~5 polyethylene structure performance characteristics and additive system

[0037]

[0038] These 5 samples above 1~5# are prepared into polyethylene for rotational molding by the method of the present invention, adopt following steps:

[0039] 1) Polyethylene resin, polyphenol hindered phenolic antioxidant, phosphite antioxidant, ultraviolet absorber, azodicarbonamide, calcium stearate and conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com