High-performance heat-conducting silica gel and preparation method thereof

A thermally conductive silicon and high-performance technology, applied in the field of high-performance thermally conductive silicone gel and its preparation, can solve the problems of reduced protection of components, reduced material elasticity and toughness, etc., to achieve lasting elasticity and toughness, improve heat resistance, Guaranteed quality reliability and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 high-performance heat-conducting silicone gel

[0042] A high-performance thermally conductive silicone gel of this embodiment, the silicone gel is prepared from component A and component B with a mass ratio of 1:1; the component A:

[0043] Vinyl-terminated silicone oil (vinyl content 0.3wt%) 16g

[0044] Alumina filler (particle size 8 ~ 10um) 84g

[0045] Platinum catalyst (3200ppm) 0.002g

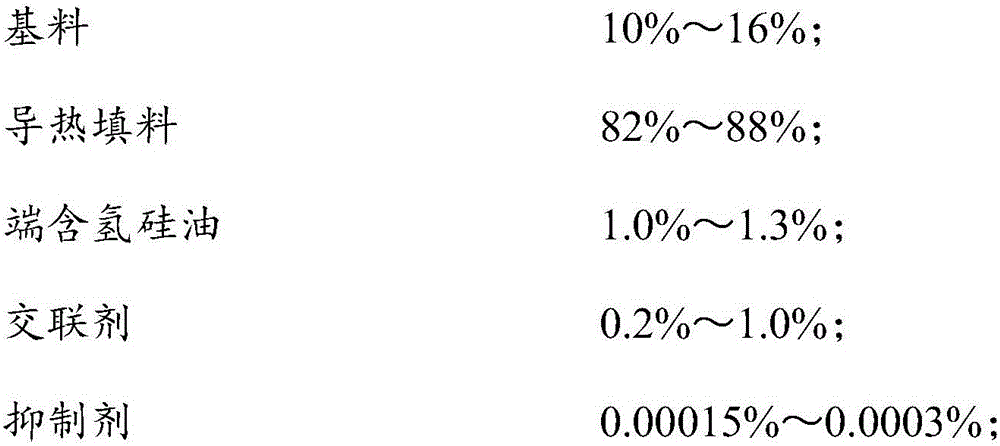

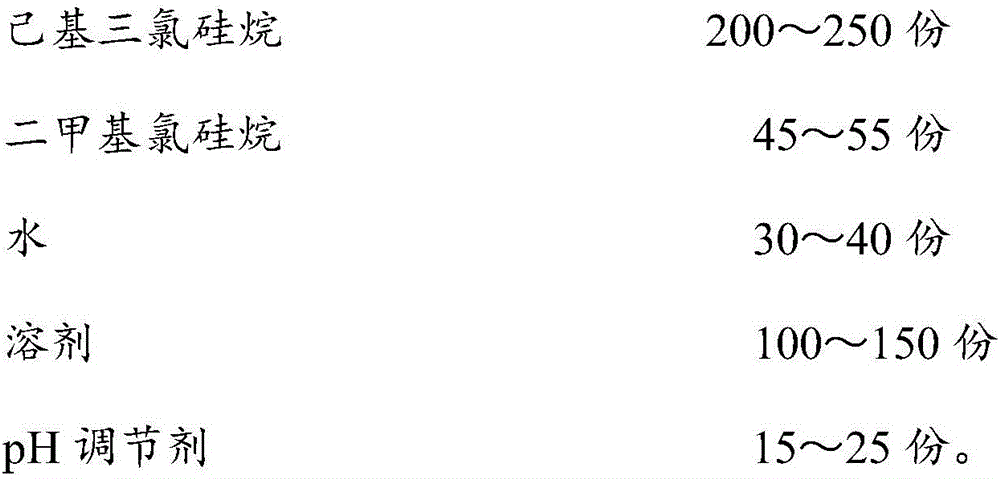

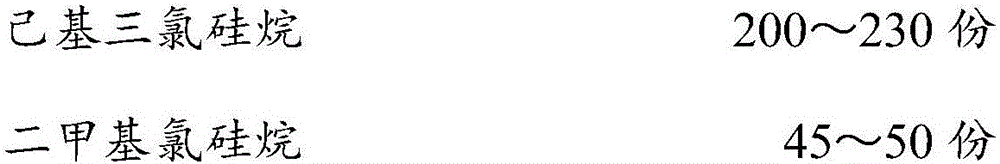

[0046] Described B component is made up of the raw material of following percentage by weight:

[0047]

[0048] The preparation method of a kind of high-performance heat-conducting silicone gel of the present embodiment comprises the following steps:

[0049] 1) Preparation of component A: Mix the base material, heat-conducting filler, and catalyst evenly to obtain the product;

[0050] 2) Preparation of component B: Mix the base material, thermally conductive filler, terminal hydrogen-containing silicone oil, crosslinking agent, and inhibitor uniformly to ob...

Embodiment 2

[0056] Embodiment 2 high-performance heat-conducting silicone gel

[0057] A high-performance thermally conductive silicone gel of this embodiment, the silicone gel is prepared from component A and component B with a mass ratio of 1:1; the component A:

[0058] Vinyl-terminated silicone oil (vinyl content 0.3wt%) 18g

[0059] Alumina filler (particle size 8 ~ 10um) 82g

[0060] Platinum catalyst (3200ppm) 0.002g

[0061] Described B component is made up of the raw material of following percentage by weight:

[0062]

[0063] The preparation method of a kind of high-performance heat-conducting silicone gel of the present embodiment comprises the following steps:

[0064] 1) Preparation of component A: Mix the base material, heat-conducting filler, and catalyst evenly to obtain the product;

[0065]2) Preparation of component B: Mix the base material, thermally conductive filler, terminal hydrogen-containing silicone oil, crosslinking agent, and inhibitor uniformly to obt...

Embodiment 3

[0071] Embodiment 3 high-performance heat-conducting silicone gel

[0072] A high-performance thermally conductive silicone gel of this embodiment, the silicone gel is prepared from component A and component B with a mass ratio of 1:1; the component A:

[0073] Vinyl-terminated silicone oil (vinyl content 0.3wt%) 15g

[0074] Alumina filler (particle size 8-10um) 85g

[0075] Platinum catalyst (3200ppm) 0.002g

[0076] Described B component is made up of the raw material of following percentage by weight:

[0077]

[0078] The preparation method of a kind of high-performance heat-conducting silicone gel of the present embodiment comprises the following steps:

[0079] 1) Preparation of component A: Mix the base material, heat-conducting filler, and catalyst evenly to obtain the product;

[0080] 2) Preparation of component B: Mix the base material, thermally conductive filler, terminal hydrogen-containing silicone oil, crosslinking agent, and inhibitor uniformly to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com