Preparation method of InP quantum dots and InP quantum dots

A technology of quantum dots and ligands, which is applied in the field of semiconductor nanomaterial preparation, can solve the problems that limit the application of InP quantum dots, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] According to a preferred embodiment of the present invention, the indium-first ligand solution and the indium-second ligand solution are obtained by adding the indium precursor to a non-coordinating solvent containing the first ligand or the second ligand of. According to different experimental schemes, when adding the indium-second ligand solution to the mixed system, the indium-second ligand solution can be the same as the indium-first ligand solution, or can be mixed with the indium-first ligand solution. The solutions are not the same.

[0026] According to a preferred embodiment of the present invention, when preparing the indium-first ligand solution or the indium-second ligand solution, the ratio of the amount of the indium precursor to the first ligand or the second ligand is controlled Within the range of 1:0.5-1:4.

[0027] In the present invention, the indium precursor includes at least one of indium acetate, indium chloride, indium carbonate, indium iodide...

specific Embodiment approach

[0031]According to a preferred embodiment of the present invention, add indium-second ligand solution or pH 3 Finally, keep the reaction for 1-120 minutes respectively, more preferably, keep the reaction for 5-30 minutes. Through this period of time, the reaction can fully proceed, the particle size of the nanocrystals becomes more uniform, and the defects on the surface gradually decrease. It should be noted that, similar to the above experimental steps, the pH 3 It is added to the mixing system in the form of gas or gas solution. According to a specific embodiment of the present invention, add indium-second ligand solution to the InP nanocrystal core with smaller particle size, react for 5-30 minutes, and then add pH 3 Gas solution, react for 5-30 minutes. According to another specific embodiment of the present invention, add the indium-first ligand solution to the InP nanocrystal core with a smaller particle size, react for 5-30 minutes, and then pass into the pH 3 Gas,...

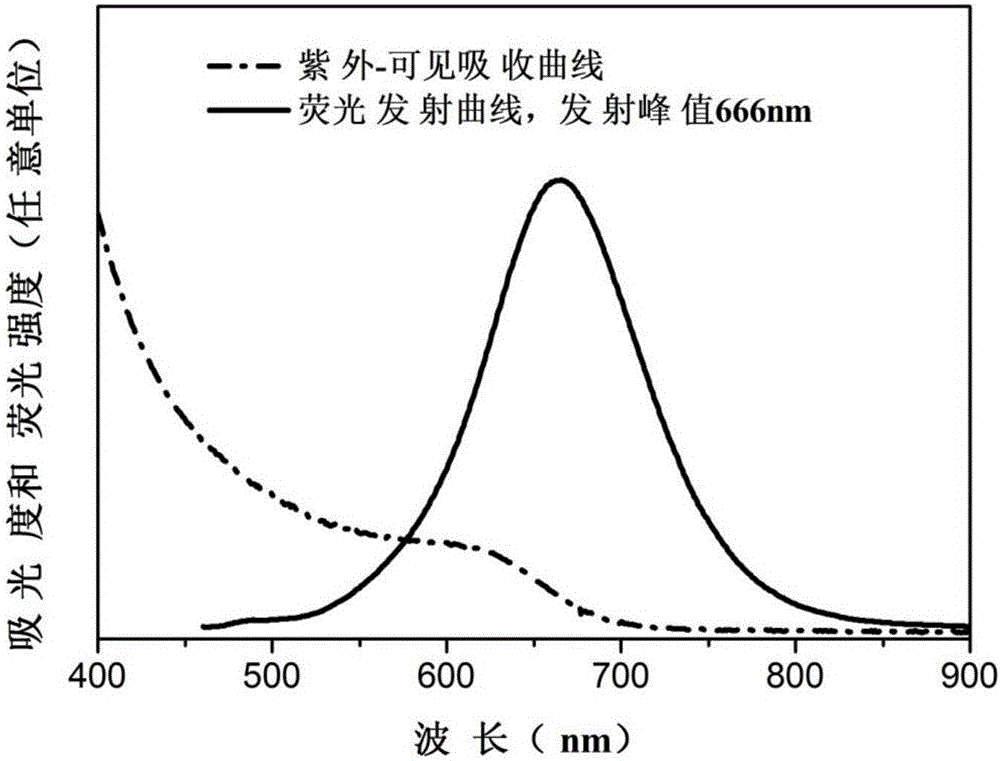

Embodiment 1

[0048] InP quantum dots with an emission peak of 666nm were prepared. Specific steps are as follows:

[0049] 1. Preparation of indium myristate (In-MA): Add 3 g of indium acetate, 5 g of myristic acid and 50 mL of 1-octadecene in a three-necked flask, feed nitrogen and heat to dissolve, and keep the reaction for 30 minutes. A clear and transparent solution of In-MA with a concentration of 0.2M was obtained;

[0050] 2. Preparation of zinc oleate (Zn-OA): add 5g of zinc acetate, 20mL of acetic acid and 30mL of 1-octadecene into a three-necked flask, feed nitrogen and heat to dissolve, keep the reaction for 30 minutes, and obtain a concentration of 0.5M Zn-OA clear transparent solution;

[0051] 3. Preparation of InP quantum dots: Add 300mg of indium acetate, 100mg of zinc acetate, 700mg of myristic acid and 10mL of 1-octadecene into a three-necked flask, pass in nitrogen gas and heat until dissolved, keep the reaction for 60 minutes, and obtain clarification Clear solution....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com