Tetracycline degrading bacterium and application thereof to livestock and poultry excrement composting treatment

A technology of tetracycline and degrading bacteria, which is applied in the field of aquaculture waste treatment, can solve the problems of few types of tetracycline-degrading microorganisms, difficulty in improving the degradation efficiency, and residues of livestock and poultry manure, so as to improve the root environment of crops, reduce tetracycline residues, and enhance The effect of nutrient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

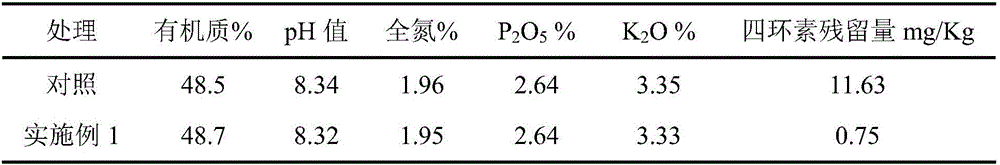

Embodiment 1

[0037]The processing object of the present invention is fresh chicken manure, the organic materials added in the composting treatment are mushroom dregs and rice bran, and the initial tetracycline content in the used chicken manure is 60mg / Kg. The number of degrading bacteria in the tetracycline-degrading bacteria fermentation broth was 1.0×10 9 CFU / mL.

[0038] The composting process is carried out in a closed composting reactor (VTD-100), and the specific steps and process conditions are as follows:

[0039] (1) 125kg of chicken manure with a moisture content of 80%, 100kg of mushroom dregs with a moisture content of 15%, and 25kg of rice bran with a moisture content of 8% are mixed evenly with a mixer. At this time, the moisture content of the mixed stock is about 46%; Divide into 2 portions, each portion is 125kg.

[0040] (2) Add 8L of the above-mentioned tetracycline-degrading bacteria fermentation liquid to one part, mix it evenly with the composting material, and the...

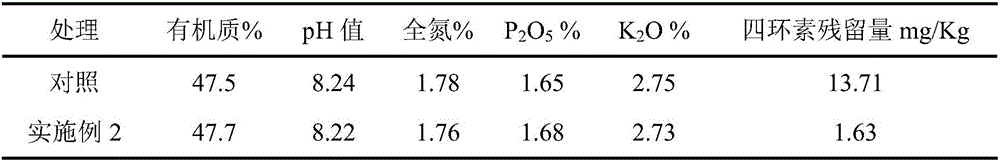

Embodiment 2

[0047] The processing object of the present invention is fresh pig manure, the organic materials added in the composting treatment are mushroom dregs and rice bran, and the initial content of tetracycline in the used pig manure is 78mg / Kg. The number of degrading bacteria in the tetracycline-degrading bacteria fermentation broth was 1.0×10 9 CFU / mL.

[0048] The composting process is carried out in a closed composting reactor (VTD-100), and the specific steps and process conditions are as follows:

[0049] (1) 125kg of pig manure with a moisture content of 78%, 100kg of mushroom dregs with a moisture content of 15%, and 25kg of rice bran with a moisture content of 8% are mixed evenly with a mixer, and the moisture content of the mixed stockpiles is about 46% at this time; Divide into 2 portions, each portion is 125kg.

[0050] (2) Add 8L of the above-mentioned tetracycline-degrading bacteria fermentation liquid to one part, mix it evenly with the composting material, and the...

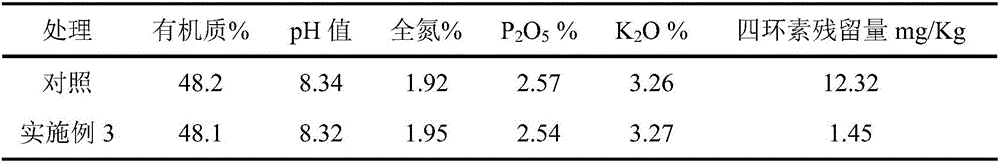

Embodiment 3

[0057] The processing object of the present invention is fresh chicken manure, the organic materials added in the composting treatment are mushroom dregs and rice bran, and the initial tetracycline content in the used chicken manure is 60mg / Kg. The number of degrading bacteria in the tetracycline-degrading bacteria fermentation broth was 1.0×10 9 CFU / mL.

[0058] The composting process is carried out by the trough composting process, and the oxygen supply method of this process is a combination of turning and aeration.

[0059] Taking the conventional compost without adding tetracycline-degrading bacteria as a control, adjust the mixing ratio of the compost according to the routine, so that the C / N ratio of the compost is 30:1 and the moisture content is about 55%. According to 1000kg of compost, add 50kg of clean water, further mix evenly, and push the evenly mixed material into the compost tank for composting treatment. On the 28th day, the pile was removed from the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com