Ultrasonic gas flowmeter signal transmitting-receiving circuit

A technology of signal sending and receiving and ultrasonic wave, which is applied in liquid/fluid solid measurement, measuring flow/mass flow, measuring device, etc., and can solve problems such as ultrasonic signal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

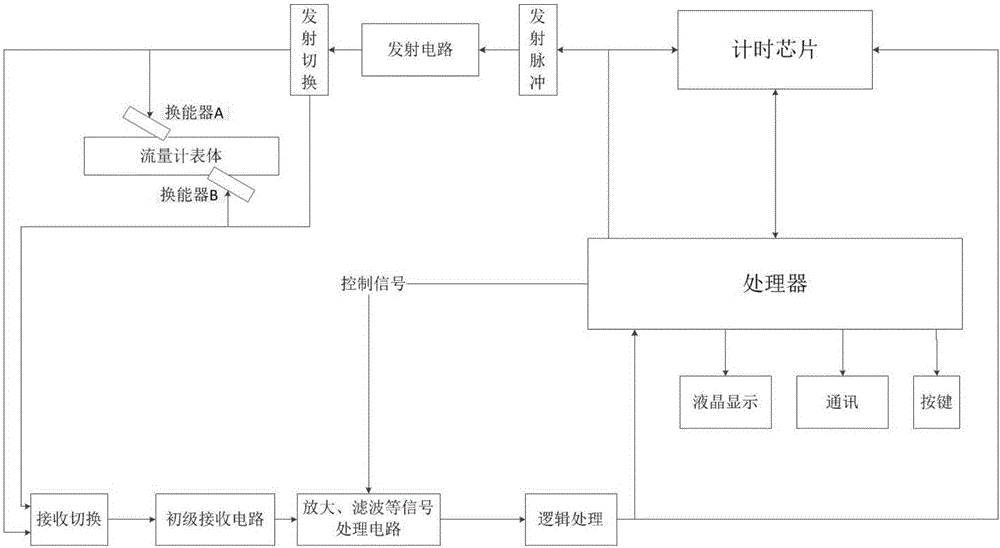

[0020] The system block diagram of the general time difference method ultrasonic flowmeter is as follows figure 1 Shown. The present invention improves the design of the transmitting circuit and the primary receiving circuit.

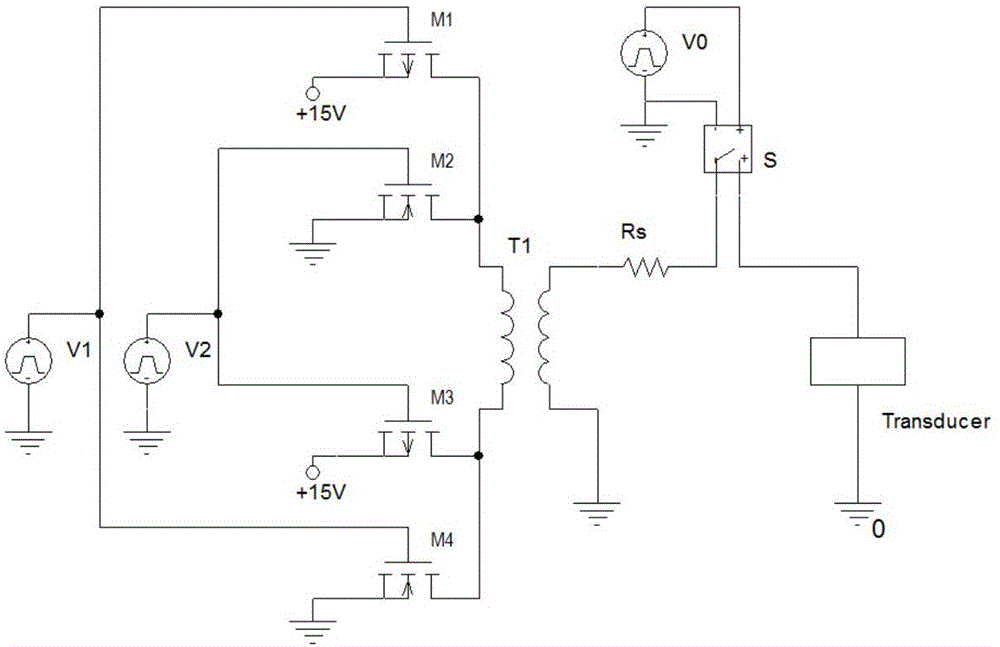

[0021] One: Design the reciprocal transmission circuit of the gas ultrasonic flowmeter, the schematic diagram is as follows figure 2 Shown.

[0022] The attenuation of ultrasonic waves in the gas is serious. In order to obtain a received signal with a relatively high signal-to-noise ratio, a relatively large pulse excitation is required for the transducer. In the figure, T1 is a high-frequency transformer with a transformation ratio of 1:3, M1, M2, M3, and M4 are power MOSFETs, which pass through the signal source V in turn 1 , V 2 By controlling the (M1, M3) and (M2, M4) groups of MOSFETs to turn on, push-pull can be used to obtain a 30V peak-to-peak square wave signal on the primary side of the transformer. S is an analog switch, the switch state is outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com